Answered step by step

Verified Expert Solution

Question

1 Approved Answer

business analytics all 3phases are here Phase 1: Careful production site planning is important to increase production efficiency which in turn Inaximizes production capacity. Machines

business analytics

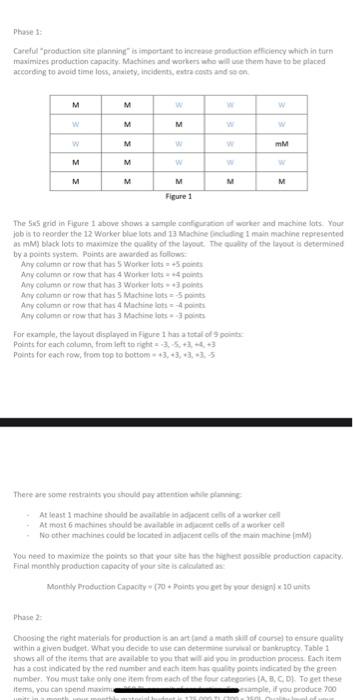

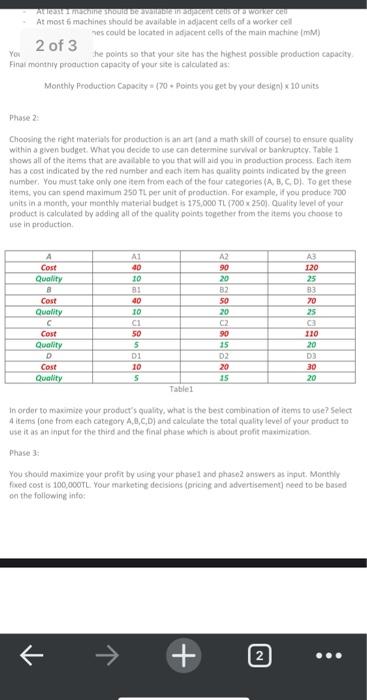

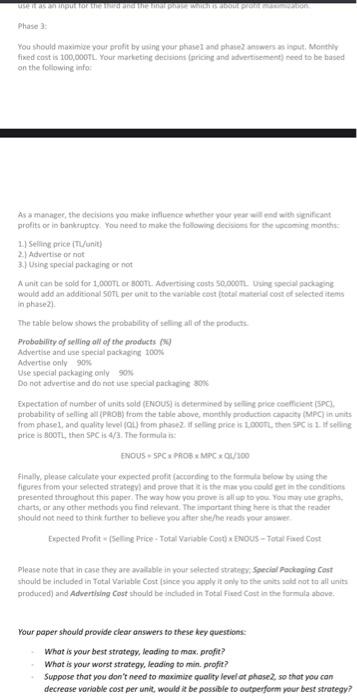

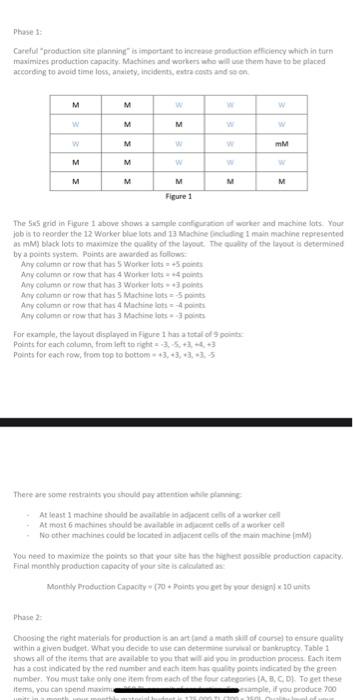

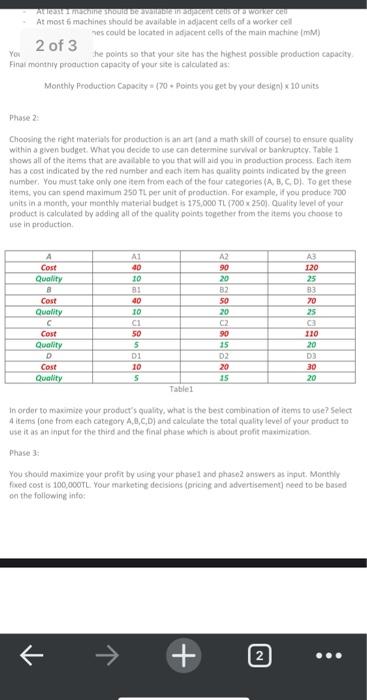

Phase 1: Careful production site planning is important to increase production efficiency which in turn Inaximizes production capacity. Machines and workers who will use them have to be placed according to avoid time foss, ansiety, incidents, extra costs and soon M M w w w M M w w M w MM M M w w M M M M M Figure 1 The Sagrid in Figure 1 above shows a sample continet and machine fots. Your job is to reorder the 12 Worker blue lots and 13 Machine dating i main machine represented mm) black lots to maximize the quality of the layout. The quality of the layout a determined by a points system. Points are awarded as follows Any columna row that has 5 Worker lots 5 points Any column orrow that has 4 Worker lots points Any column or row that has 3 Workers points Any column or row that has 5 Machine lots = 5 points Any column or row that has 4 Machine lots-4 points Any colomnar row that has 3 Machine lots points For example, the layout displayed in Figure I has a total of points Points for each column, from left to right3.5-43 Points for each row from top to bottom 13.3.3.15 There are some restraints you should pay attention while planning At least machine should be valabile in acest co workel At most 6 machines should be available and cells of a worker celt No other machines could be located in adjacents of the main machine (MM) You need to maximize the points so that your site has the rest possible production capacity. Finalmonthly production capacity of your site is called Monthly Production Capacity (70 + Points you get by your designs x 20 units Phase Choosing the night materials for production is an art and a maths of course) to ensure quality within a given budget. What you decide to use can determinal or bankruptcy. Table 1 shows all of the items that are available to you that will you in production process Each item has a cost indicated by the red number and each tematy points indicated by the green number. You must take only one item from each of the four categories AB,CD To get these items, you can spend me ample, if you produce 700 Amnes de Vincent ces or worteceu At most machines should be available in adjacent cells of a worker cel mes could be located in adjacent cells of the main machine (M) 2 of 3 You he points so that your site has the highest possible production capacity Final monthly production capacity of your site is calculated as: Monthly Production Capacity (70 Points you get by your design, 10 units Phase 2 Choosing the right materials for production is an art (and a math skill of course to ensure quality within a given budget. What you decide to use can determine survival or bankruptcy. Table 1 shows all of the items that are available to you that will aid you in production process. Each item has a cost indicated by the red number and each item has quality points indicated by the green number. You must take only one item from each of the four categories (A, B,CD). To get these items, you can spend maximum 250 TL per unit of production. For example, if you produce 700 units in a month, your monthly material budget is 175.000 TL (700x250), Quality level of your product is calculated by adding all of the quality points together from the items you choose to use in production A3 120 25 33 70 25 A Cost Quality B Cost Quality C Cost Quality D Cose Quality A1 40 10 81 40 10 c1 50 5 D1 10 5 90 20 82 50 20 C2 90 15 D2 20 15 110 20 D3 30 20 Tablet In order to maximize your product's quality, what is the best combination of items to use? Select 4 items (one from each category A,B,C,D) and calculate the total quality level of your product to use it as an input for the third and the final phase which is about profit maximization Phase 3: You should maximise your profit by using your phases and phase2 answers as input. Monthly faced cost is 100,000TL. Your marketing decisions (pricing and advertisement Deed to be based on the following into + 2 ... Phase You should maxime your profit by using your phase and phasenwersas inout Month fixed cost is 100,000TL Your marketing decisions (pricing and advertisement need to be based on the following info: As a manager, the decisions you make intuence whether your year will end with significant profits or in bankruptcy. You need to make the following decisions for the upcoming months 1. Selling price/unit) 2.) Advertise or not 3.) Using special packaging or not A unit can be sold for 1.000.0r Hoon Advertising costs 50.000mUsing special packaging would add an additional SOTL per unit to the variable cost total material cost of selected items in phase2) The table below shows the probability of setting all of the products Probability of selling all of the products (0) Advertise and use special packaging 100% Advertise only 90% Use special packaging only 90% Do not advertise and do not use special packaging 30% Expectation of number of units sold (ENOUS) is determined by se price coefficient (50) probability of selling (PROB) from the table above, monthly production (MPC) i units from phase, and quality level (L) from phase selling price is Looo,then SPC 81 If selling price is 800TL, then SPC4/3. The formulas ENOUS SPC PROBMPC200/100 Finally, please calculate your expected profit (according to the form below by using the figures from your selected strategy and prove that is theme you could get in the conditions presented throughout this paper. The way how you prove is all up to you. You may be graphs charts, or any other methods you find relevant. The important thing here is that the radi should not need to thinkfurther to believe you after she/herads your awer Expected Profit (eling Price - Total Variable COM A ENOUS - Total Fixed Cost Please note that in case they are available in your selected strateer Special Packaging Cost should be included in Total variable Cost (since you apply it only to the cits sold not to all units produced and Advertising Cost should be included in Total Fixed Cost in the formula above Your paper should provide clear answers to these key questions What is your best strategy, leading to max, profit? What is your worst strategy, leading to min profit? Suppose that you don't need to maximize quality level of phese so that you can decrease voriable cost per unit would it be possible to outperform your best strategy? Phase 1: Careful production site planning is important to increase production efficiency which in turn Inaximizes production capacity. Machines and workers who will use them have to be placed according to avoid time foss, ansiety, incidents, extra costs and soon M M w w w M M w w M w MM M M w w M M M M M Figure 1 The Sagrid in Figure 1 above shows a sample continet and machine fots. Your job is to reorder the 12 Worker blue lots and 13 Machine dating i main machine represented mm) black lots to maximize the quality of the layout. The quality of the layout a determined by a points system. Points are awarded as follows Any columna row that has 5 Worker lots 5 points Any column orrow that has 4 Worker lots points Any column or row that has 3 Workers points Any column or row that has 5 Machine lots = 5 points Any column or row that has 4 Machine lots-4 points Any colomnar row that has 3 Machine lots points For example, the layout displayed in Figure I has a total of points Points for each column, from left to right3.5-43 Points for each row from top to bottom 13.3.3.15 There are some restraints you should pay attention while planning At least machine should be valabile in acest co workel At most 6 machines should be available and cells of a worker celt No other machines could be located in adjacents of the main machine (MM) You need to maximize the points so that your site has the rest possible production capacity. Finalmonthly production capacity of your site is called Monthly Production Capacity (70 + Points you get by your designs x 20 units Phase Choosing the night materials for production is an art and a maths of course) to ensure quality within a given budget. What you decide to use can determinal or bankruptcy. Table 1 shows all of the items that are available to you that will you in production process Each item has a cost indicated by the red number and each tematy points indicated by the green number. You must take only one item from each of the four categories AB,CD To get these items, you can spend me ample, if you produce 700 Amnes de Vincent ces or worteceu At most machines should be available in adjacent cells of a worker cel mes could be located in adjacent cells of the main machine (M) 2 of 3 You he points so that your site has the highest possible production capacity Final monthly production capacity of your site is calculated as: Monthly Production Capacity (70 Points you get by your design, 10 units Phase 2 Choosing the right materials for production is an art (and a math skill of course to ensure quality within a given budget. What you decide to use can determine survival or bankruptcy. Table 1 shows all of the items that are available to you that will aid you in production process. Each item has a cost indicated by the red number and each item has quality points indicated by the green number. You must take only one item from each of the four categories (A, B,CD). To get these items, you can spend maximum 250 TL per unit of production. For example, if you produce 700 units in a month, your monthly material budget is 175.000 TL (700x250), Quality level of your product is calculated by adding all of the quality points together from the items you choose to use in production A3 120 25 33 70 25 A Cost Quality B Cost Quality C Cost Quality D Cose Quality A1 40 10 81 40 10 c1 50 5 D1 10 5 90 20 82 50 20 C2 90 15 D2 20 15 110 20 D3 30 20 Tablet In order to maximize your product's quality, what is the best combination of items to use? Select 4 items (one from each category A,B,C,D) and calculate the total quality level of your product to use it as an input for the third and the final phase which is about profit maximization Phase 3: You should maximise your profit by using your phases and phase2 answers as input. Monthly faced cost is 100,000TL. Your marketing decisions (pricing and advertisement Deed to be based on the following into + 2 ... Phase You should maxime your profit by using your phase and phasenwersas inout Month fixed cost is 100,000TL Your marketing decisions (pricing and advertisement need to be based on the following info: As a manager, the decisions you make intuence whether your year will end with significant profits or in bankruptcy. You need to make the following decisions for the upcoming months 1. Selling price/unit) 2.) Advertise or not 3.) Using special packaging or not A unit can be sold for 1.000.0r Hoon Advertising costs 50.000mUsing special packaging would add an additional SOTL per unit to the variable cost total material cost of selected items in phase2) The table below shows the probability of setting all of the products Probability of selling all of the products (0) Advertise and use special packaging 100% Advertise only 90% Use special packaging only 90% Do not advertise and do not use special packaging 30% Expectation of number of units sold (ENOUS) is determined by se price coefficient (50) probability of selling (PROB) from the table above, monthly production (MPC) i units from phase, and quality level (L) from phase selling price is Looo,then SPC 81 If selling price is 800TL, then SPC4/3. The formulas ENOUS SPC PROBMPC200/100 Finally, please calculate your expected profit (according to the form below by using the figures from your selected strategy and prove that is theme you could get in the conditions presented throughout this paper. The way how you prove is all up to you. You may be graphs charts, or any other methods you find relevant. The important thing here is that the radi should not need to thinkfurther to believe you after she/herads your awer Expected Profit (eling Price - Total Variable COM A ENOUS - Total Fixed Cost Please note that in case they are available in your selected strateer Special Packaging Cost should be included in Total variable Cost (since you apply it only to the cits sold not to all units produced and Advertising Cost should be included in Total Fixed Cost in the formula above Your paper should provide clear answers to these key questions What is your best strategy, leading to max, profit? What is your worst strategy, leading to min profit? Suppose that you don't need to maximize quality level of phese so that you can decrease voriable cost per unit would it be possible to outperform your best strategy all 3phases are here

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started