Question

By the middle of the 1990s Xerox had integrated its European manufacturing and logistics processes and organisations developing an end-to-end approach to its supply chain.

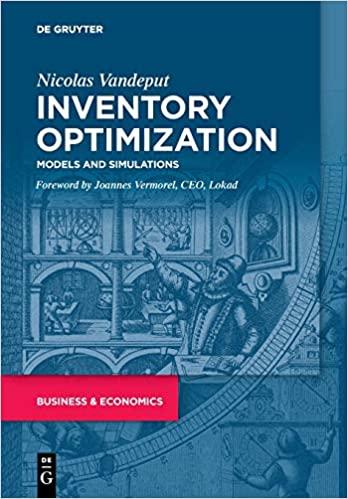

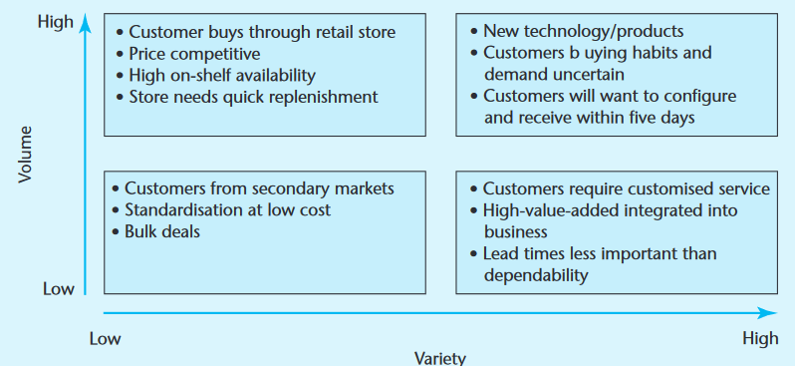

By the middle of the 1990s Xerox had integrated its European manufacturing and logistics processes and organisations developing an end-to-end approach to its supply chain. This had delivered massive financial benefits to the company both in terms of inventory reduction and operating cost. At the time, it was to launch a new range of products and to extend its market coverage and it was recognised that the predominantly 'one size fits all' approach to customer fulfilment was not competitive. The company embarked on a programme of asking customers about their requirements for overall fulfilment and understanding supply chain competitive performance. Based on market/customer expectations the company segmented its supply chain into four different streams across the total source-plan-make-deliver process. The segmentation of the market/customer expectations are shown in Figure 1 and the supply chain response in Figure 2. Volume represents the number of orders/shipments; variety reflects the combination of product variation and day-to-day demand variability.

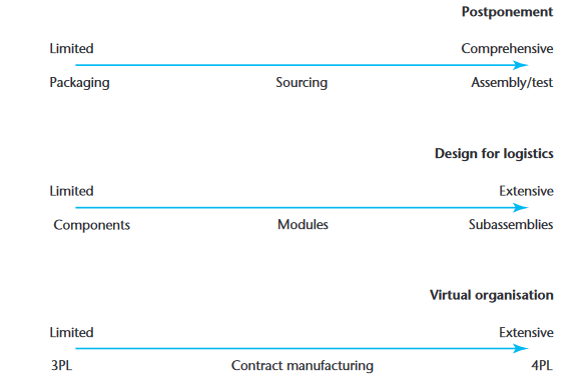

The organisation and the processes of the supply chain needed to operate differently since the priorities of the market and customers were different. Different performance measures and targets were established for each segment and cultures and incentives put in place to drive the change. In all cases the company operated with outsourced partners as part of the supply chain operations but the balance between outsourced and in-house varied depending on the skills and flexibility required. As 'adding customer uniqueness as late as possible' was a key element in the process design, collaboration with the product design teams and suppliers became essential to engineer supply-chain-friendly products.

In particular in the high-volume/high-variety segment the customer order is directed to the integration centre at the end of the line, which has less than five days to finalise the product and deliver to the end-consumer. This could only be achieved by engineering the product to a modular design with final configuration from stock of 'neutral' modules and adding customer-unique options. This capability required flexibility and agility in all areas of the supply chain. In turn, this required investment in the skills needed for planning demand and supply so that capacity and inventories could meet the variable demand.

At the time, the segmentation approach allowed the company to fulfil the majority of its European customer orders from a European supply, with the exception of the high-volume/low-variety segment which supplied customers through distributors and retailers.

This approach not only improved measures of customer responsiveness but also improved inventory turns, reducing the need for stocks below the European level and reducing overall supply chain costs. Inherent in the design was not only the flexibility in operation but the ability to create and restructure the segments depending on changes to market and customer needs. This configuration of the Xerox supply chain segmentation had a life of approximately four years.

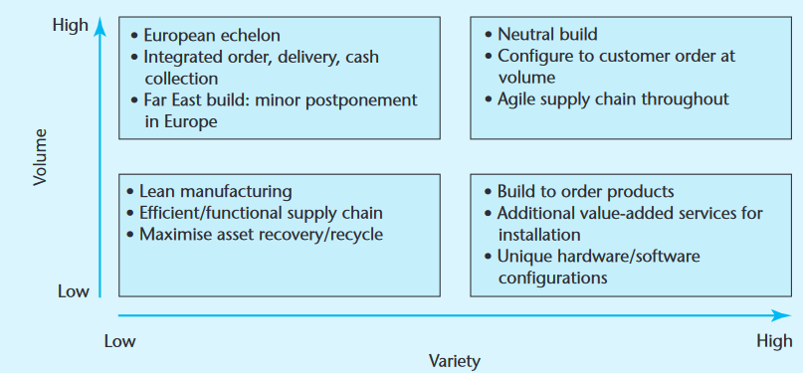

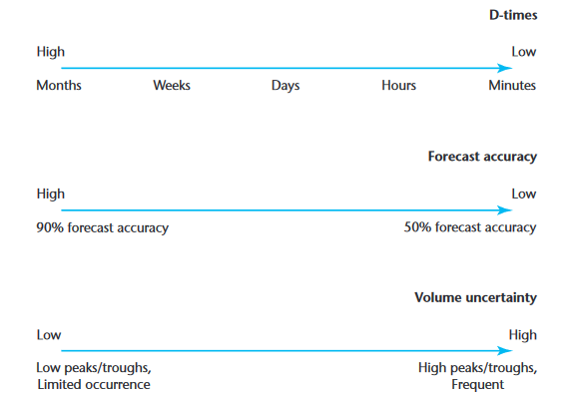

Map the Xerox segments and market response (Figures 1 and 2) onto demand influences and supply capabilities in Figures 3 and 4 as far as you can, making assumptions where necessary. How closely does the actual match the theoretical?

\begin{tabular}{|l|l|} High & -Customerbuysthroughretailstore-Pricecompetitive-Highon-shelfavailability-Storeneedsquickreplenishment \\ \hline \end{tabular} - New technology/products - Customers b uying habits and demand uncertain - Customers will want to configure and receive within five days - Customers from secondary markets - Customers require customised service - Standardisation at low cost - High-value-added integrated into - Bulk deals business - Lead times less important than dependability Low High Variety D-times Forecast accuracy Volume uncertainty Postponement Design for logistics Virtual organisation

\begin{tabular}{|l|l|} High & -Customerbuysthroughretailstore-Pricecompetitive-Highon-shelfavailability-Storeneedsquickreplenishment \\ \hline \end{tabular} - New technology/products - Customers b uying habits and demand uncertain - Customers will want to configure and receive within five days - Customers from secondary markets - Customers require customised service - Standardisation at low cost - High-value-added integrated into - Bulk deals business - Lead times less important than dependability Low High Variety D-times Forecast accuracy Volume uncertainty Postponement Design for logistics Virtual organisation Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started