Answered step by step

Verified Expert Solution

Question

1 Approved Answer

C) DETERMINE THE JOB LIST ON THE FIRST SIX DAYS IN WHICH YOU HAVE PRODUCTION AND PRODUCE THE OPTIMUM PRODUCTION SCHEDULE. D) PREPARE A REPORT

C) DETERMINE THE JOB LIST ON THE FIRST SIX DAYS IN WHICH YOU HAVE PRODUCTION AND PRODUCE THE OPTIMUM PRODUCTION SCHEDULE.

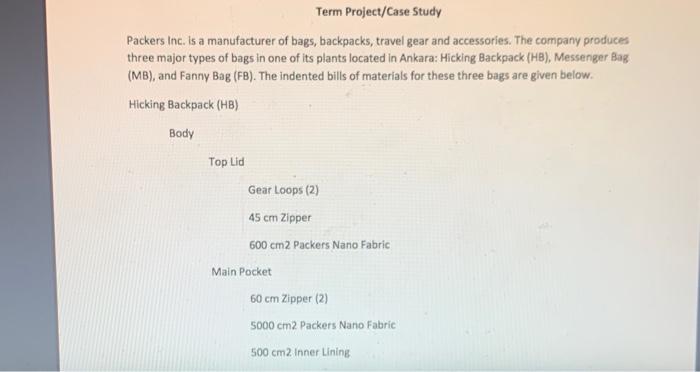

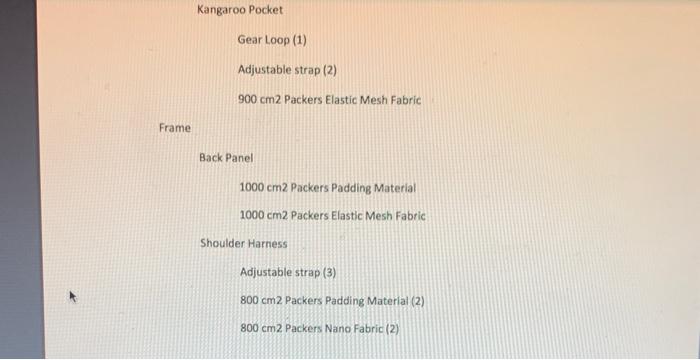

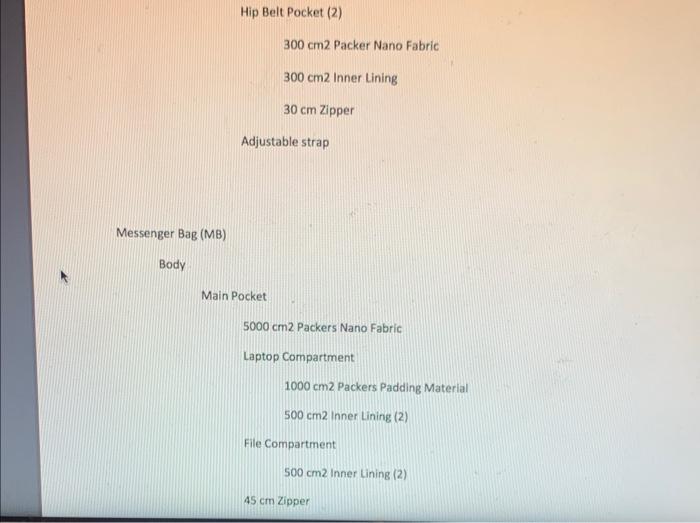

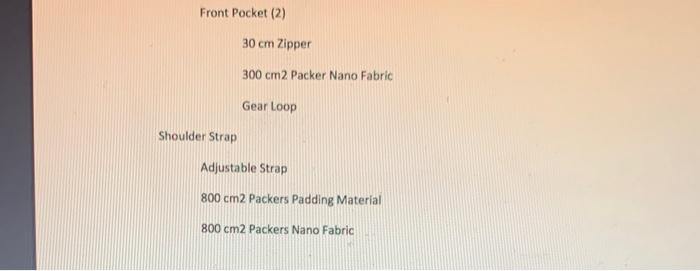

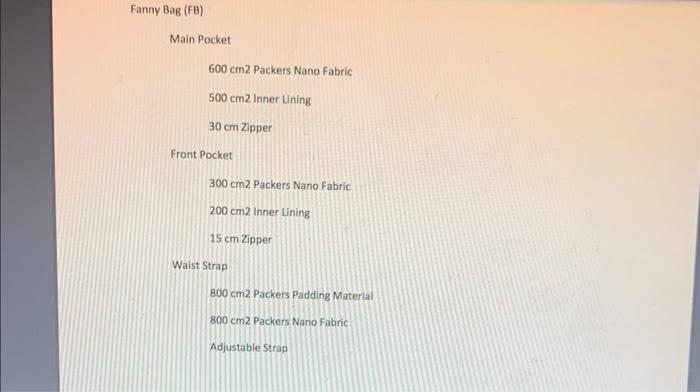

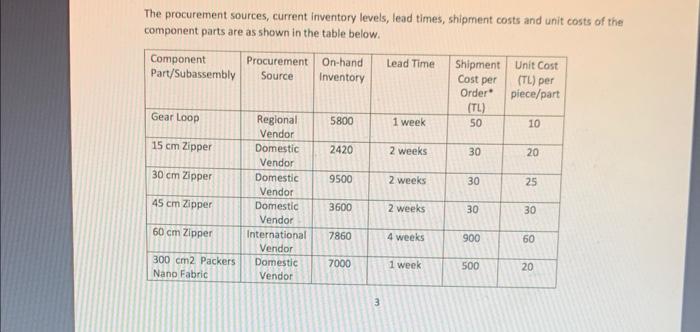

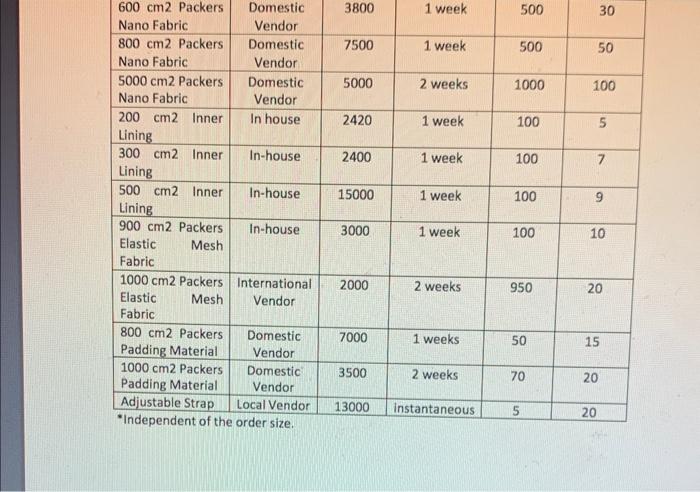

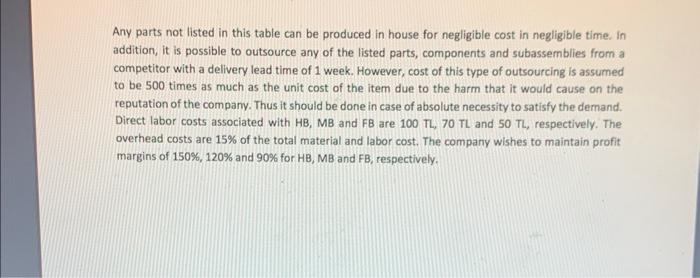

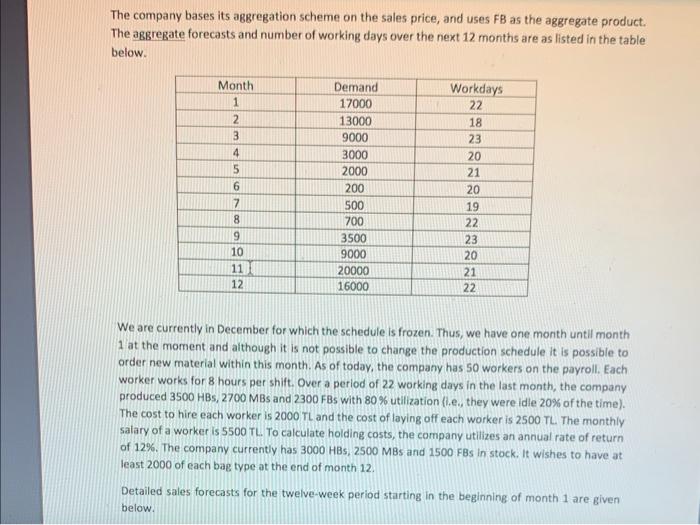

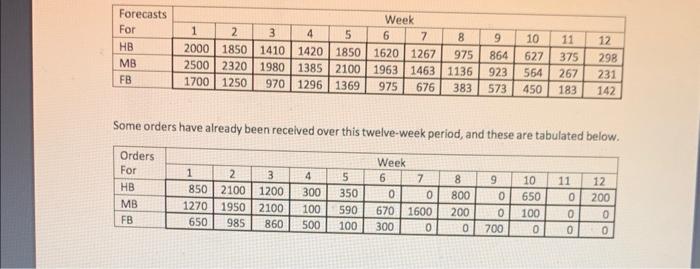

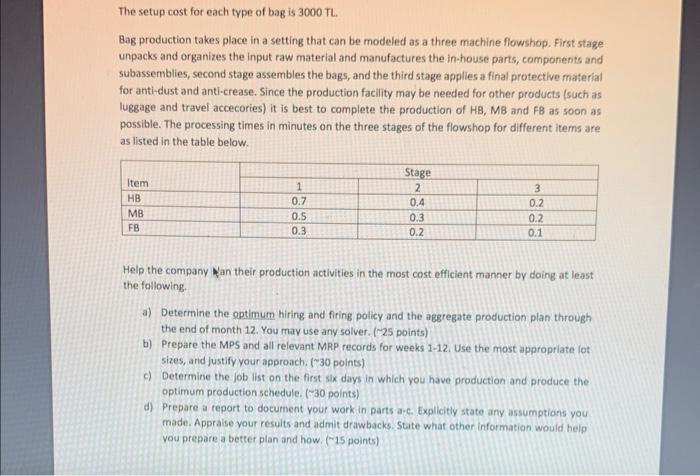

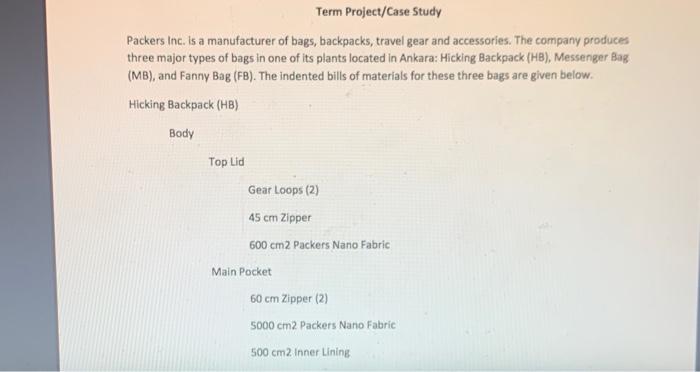

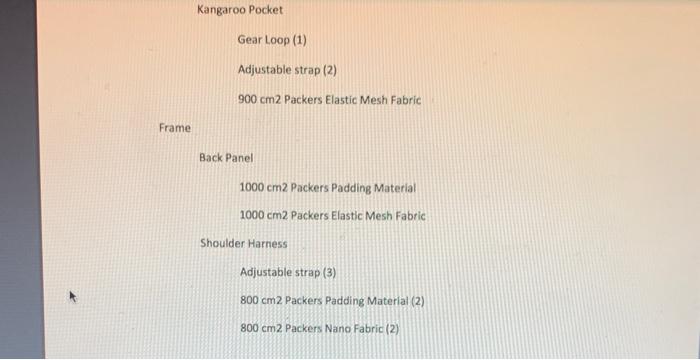

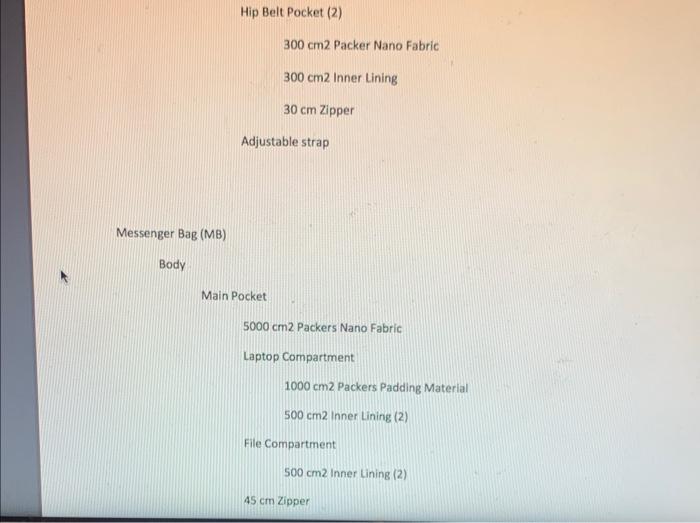

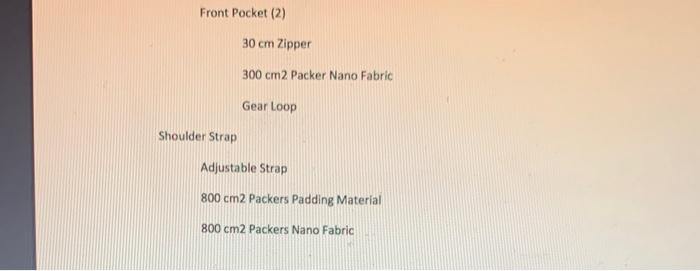

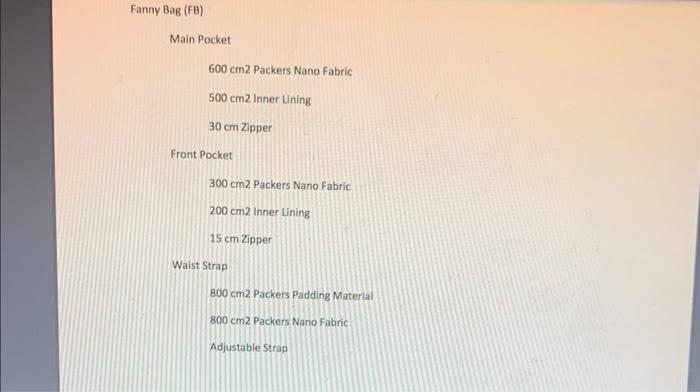

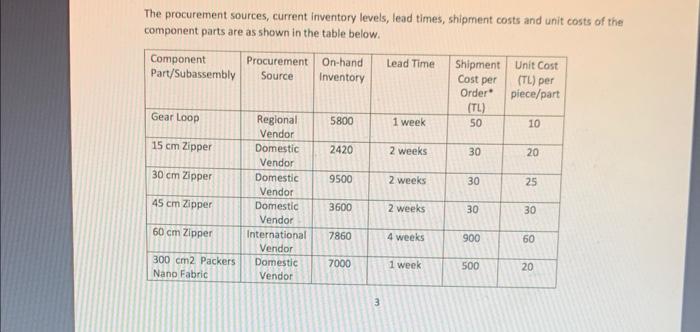

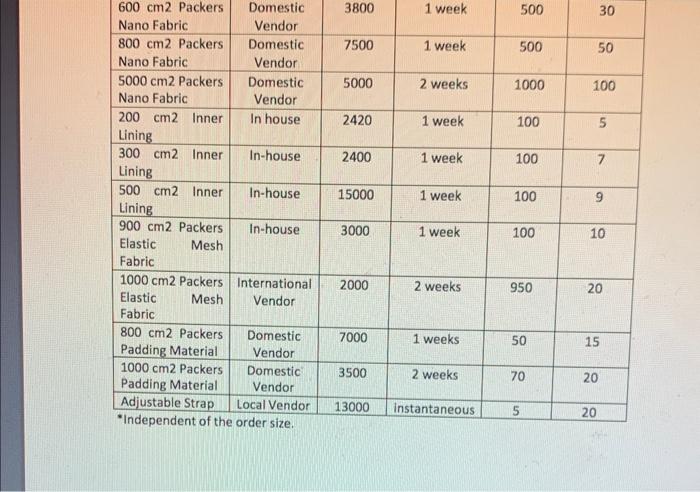

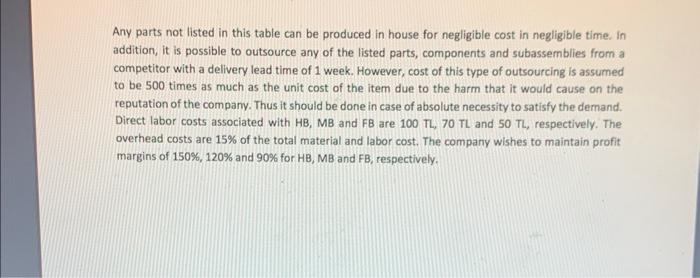

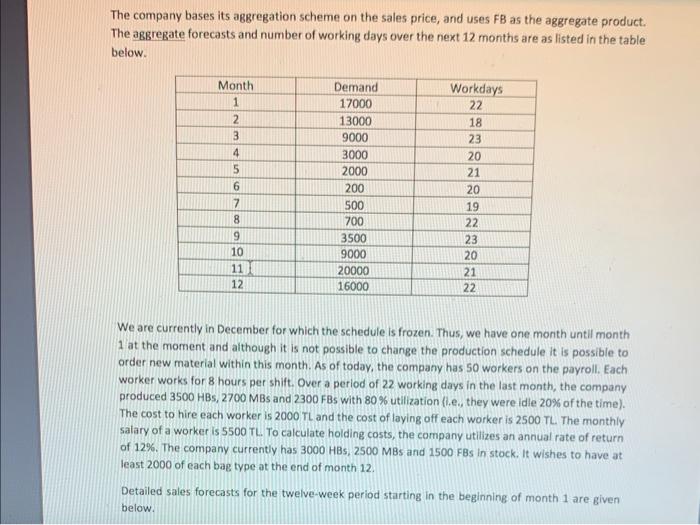

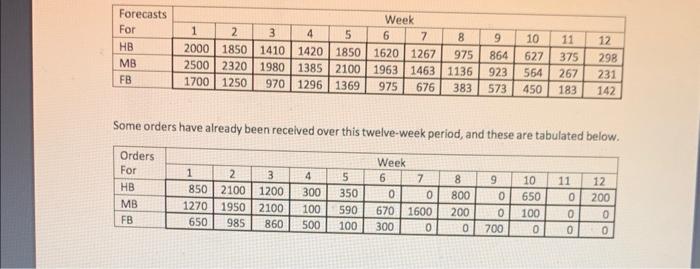

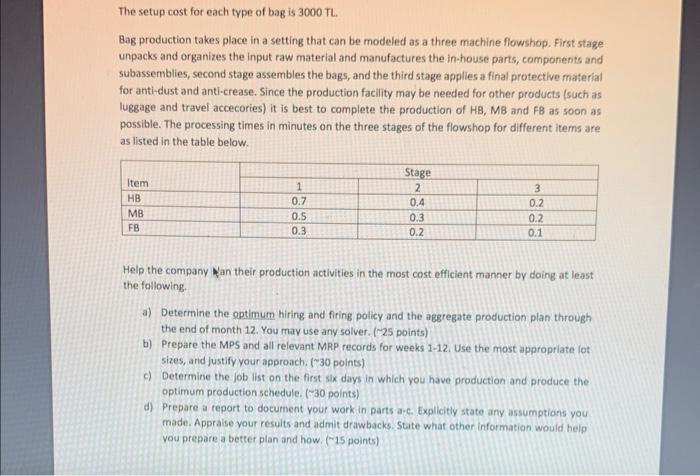

Packers Inc. is a manufacturer of bags, backpacks, travel gear and accessories. The company produces three major types of bags in one of its plants located in Ankara: Hicking Backpack (HB), Messenger Bag (MB), and Fanny Bag (FB). The indented bills of materials for these three bags are given below. Hicking Backpack (HB) Body Top Lid Gear Loops (2) 45cm Zipper 600cm2 Packers Nano Fabric Main Pocket 60cm Zipper (2) 5000cm2 Packers Nano Fabric 500cm 2. Inner Lining Kangaroo Pocket Gear Loop (1) Adjustable strap (2) 900cm2 Packers Elastic Mesh Fabric Frame Back Panel 1000cm2 Packers Padding Material 1000cm2 Packers Elastic Mesh Fabric Shoulder Harness Adjustable strap (3) 800cm2 Packers Padding Material (2) 800cm2 Packers Nano Fabric (2) Hip Belt Pocket (2) 300cm2 Packer Nano Fabric 300cm2 Inner Lining 30cm Zipper Adjustable strap Messenger Bag (MB) Body Main Pocket 5000cm2 Packers Nano Fabric Laptop Compartment 1000cm2 Packers Padding Material 500cm2 Inner Lining (2) File Compartment 500cm2 Inner Lining (2) 45cm Zipper Front Pocket (2) 30cm Zipper 300cm2 Packer Nano Fabric Gear Loop Shoulder Strap Adjustable Strap 800cm2 Packers Padding Material 800cm2 Packers Nano Fabric Main Pocket 600cm2 Packers Nano Fabric 500cm2 Inner Lining 30cm Zipper Front Pocket 300cm2 Packers Nano Fabric 200cm2 Inner Lining 15cm Zipper Waist Strap 800cm2 Packers Padding Material 800cm2 Packers Nano Fabric Adjustable Strap The procurement sources, current inventory levels, lead times, shipment costs and unit costs of the component parts are as shown in the table below. "Independent of the order size. Any parts not listed in this table can be produced in house for negligible cost in negligible time. In addition, it is possible to outsource any of the listed parts, components and subassemblies from a competitor with a delivery lead time of 1 week. However, cost of this type of outsourcing is assumed to be 500 times as much as the unit cost of the item due to the harm that it would cause on the reputation of the company. Thus it should be done in case of absolute necessity to satisfy the demand. Direct labor costs associated with HB, MB and FB are 100TL,70TL and 50TL, respectively. The overhead costs are 15% of the total material and labor cost. The company wishes to maintain profit margins of 150%,120% and 90% for HB,MB and FB, respectively, The company bases its agrregation scheme on the sales price, and uses FB as the aggregate product. The aggregate forecasts and number of working days over the next 12 months are as listed in the table below. We are currently in December for which the schedule is frozen. Thus, we have one month until month 1 at the moment and although it is not possible to change the production schedule it is possible to order new material within this month. As of today, the company has 50 workers on the payroll. Each worker works for 8 hours per shift. Over a period of 22 working days in the last month, the company produced 3500HBs,2700MBs and 2300FBs with 80% utilization (li.e., they were idle 20% of the time). The cost to hire each worker is 2000TL and the cost of laying off each worker is 2500TL. The monthly salary of a worker is 5500TL. To calculate holding costs, the company utilizes an annual rate of return of 12%. The company currently has 3000HBs,2500MBs and 2500 FBs in stock. It wishes to have at least 2000 of each bag type at the end of month 12. Detailed sales forecasts for the twelve-week period starting in the beginning of month 1 are given below. Some orders have already been received over this twelve-week period, and these are tabulated below. The setup cost for each type of bag is 3000TL. Bag production takes place in a setting that can be modeled as a three machine flowshop. First stage unpacks and organizes the input raw material and manufactures the in-house parts, components and subassemblies, second stage assembles the bags, and the third stage applies a final protective material for anti-dust and anti-crease. Since the production facility may be needed for other products (such as luggage and travel accecories) it is best to complete the production of HB,MB and FB as soon as possible. The processing times in minutes on the three stages of the flowshop for different items are as listed in the table below. Help the company Yan their production activities in the most cost efficient manner by doing at least the following. a) Determine the optimum hiring and fiting policy and the aggregate production plan through the end of month 12. You may use any solver. (25 points) b) Prepare the MPS and all relevant MRP records for weeks 1-12. Use the most appropriate lot sizes, and justify your approach. ( 30 points) c) Determine the job list on the first six days in which you have production and produce the optimum production schedule. (30 points) d) Prepare a report to document your work in parts a-c. Explicitly state any assumptions you made. Appraise your results and admit drawbacks. State what other information would help you prepare a better plan and how. ( 15 points) D) PREPARE A REPORT TO DOCUMENT YOUR WORK IN PARTS A-C. EXPLICITLY STATE ANY ASSUMPTIONS YOU MADE. APPRAISE YOUR RESULTS AND ADMIT DRAWBACKS. STATE WHAT OTHER INFORMATION WOULD HELP YOU PREPARE A BETTER PLAN AND HOW.

These two questions are really important for me to be answered. Please help me as soon as possible. I only have 12 hours for this.

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started