CALCULATE THE RATE OF REACTION -rA FOR THE FOLLOWING PROBLEM

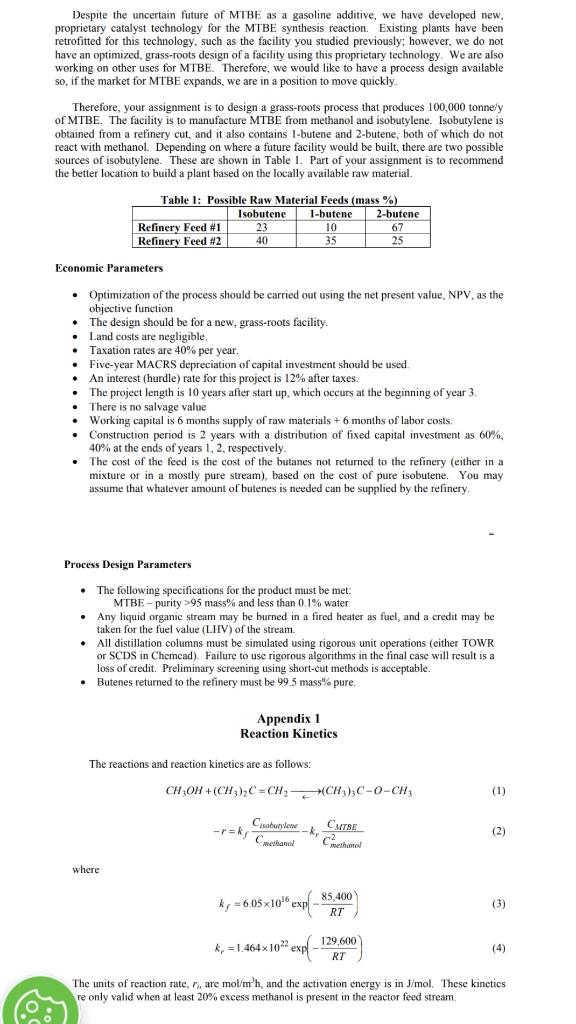

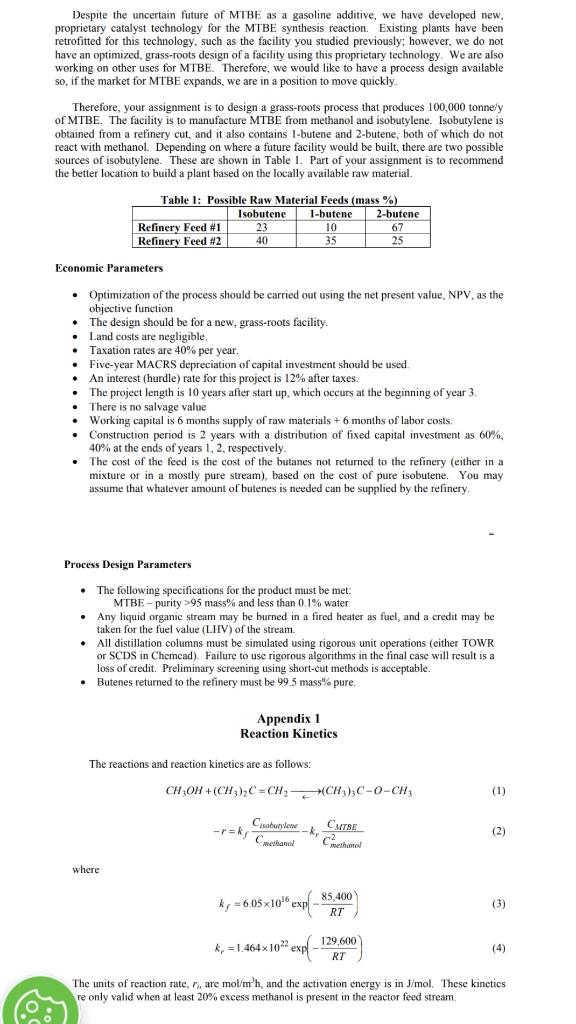

Despite the uncertain future of MIBE as a gasoline additive, we have developed new. proprietary catalyst technology for the MTBE synthesis reaction. Existing plants have been retrofitted for this technology, such as the facility you studied previously; however, we do not have an optimized, grass-roots design of a facility using this proprietary technology. We are also working on other uses for MTBE. Therefore, we would like to have a process design available so, if the market for MTBE expands, we are in a position to move quickly. Therefore, your assignment is to design a grass-roots process that produces 100,000 tonne/y of MTBE. The facility is to manufacture MTBE from methanol and isobutylene. Isobutylene is obtained from a refinery cut, and it also contains 1-butene and 2-butene, both of which do not react with methanol. Depending on where a future facility would be built, there are two possible sources of isobutylene. These are shown in Table 1. Part of your assignment is to recommend the better location to build a plant based on the locally available raw material. Economic Parameters - Optimization of the process should be carried out using the net present value, NPV, as the objective function - The design should be for a new, grass-roots facility. - Land costs are negligible. - Taxation rates are 40% per year. - Five-year MACRS depreciation of capital investment should be used. - An interest (hurdle) rate for this project is 12% after taxes. - The project length is 10 years after start up, which occurs at the beginning of year 3 . - There is no salvage value - Working capital is 6 months supply of raw materials +6 months of labor costs. - Construction period is 2 years with a distribution of fixed capital investment as 60%. 40% at the ends of years 1,2 , respectively - The cost of the feed is the cost of the butanes not returned to the refinery (either in a mixture or in a mostly pure stream), based on the cost of pure isobutene. You may assume that whatever amount of butenes is needed can be supplied by the refinery. Process Design Parameters - The following specifications for the product must be met: MTBE - purity >95 mass % and less than 0.1% water - Any liquid organic stream may be burned in a fired heater as fuel, and a credit may be taken for the fuel value (LHV) of the stream. - All distillation columns must be simulated using rigorous unit operations (either TOWR or SCDS in Chemead). Failure to use rigorous algorithms in the final case will result is a loss of credit. Preliminary screening using short-cut methods is acceptable. - Butenes returned to the refinery must be 99.5 mass % pure. Appendix 1 Reaction Kinetics The reactions and reaction kinetics are as follows: CH3OH+(CH3)2C=CH2(CH3)3COCH3r=kfCmethanolCisoburtenekrCmethanol2CMTSE where kf=6.051016exp(RT85,400)kr=1.4641022exp(RT129,600) The units of reaction rate, rh, are mol3m3h, and the activation energy is in J/mol. These kinetics re only valid when at least 20% excess methanol is present in the reactor feed stream