Answered step by step

Verified Expert Solution

Question

1 Approved Answer

can anyone make it like an assignment. Clements vineyards ('Clements) is an independent wine producer located in the Niagara, Ontario region and is owned by

can anyone make it like an assignment.

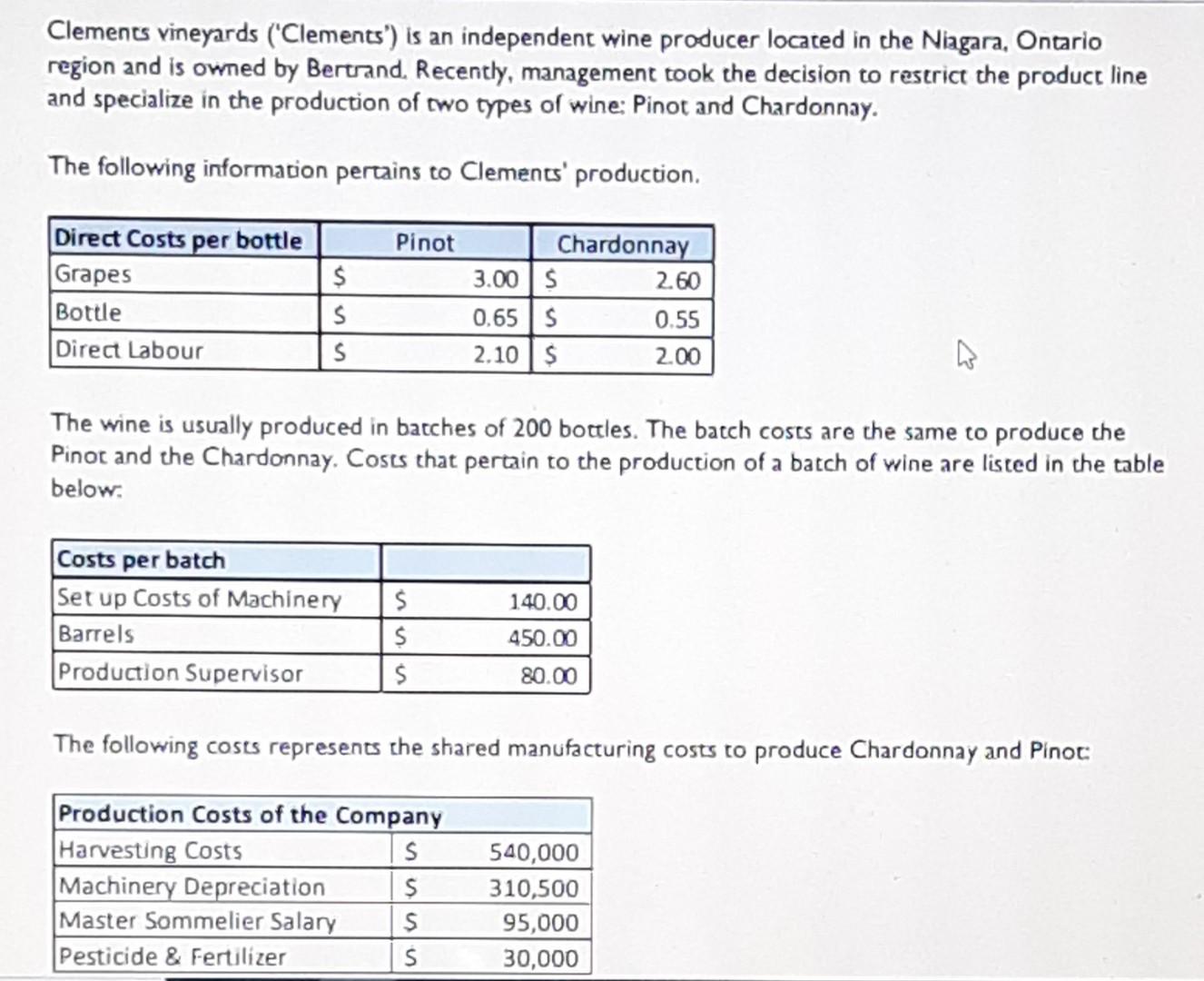

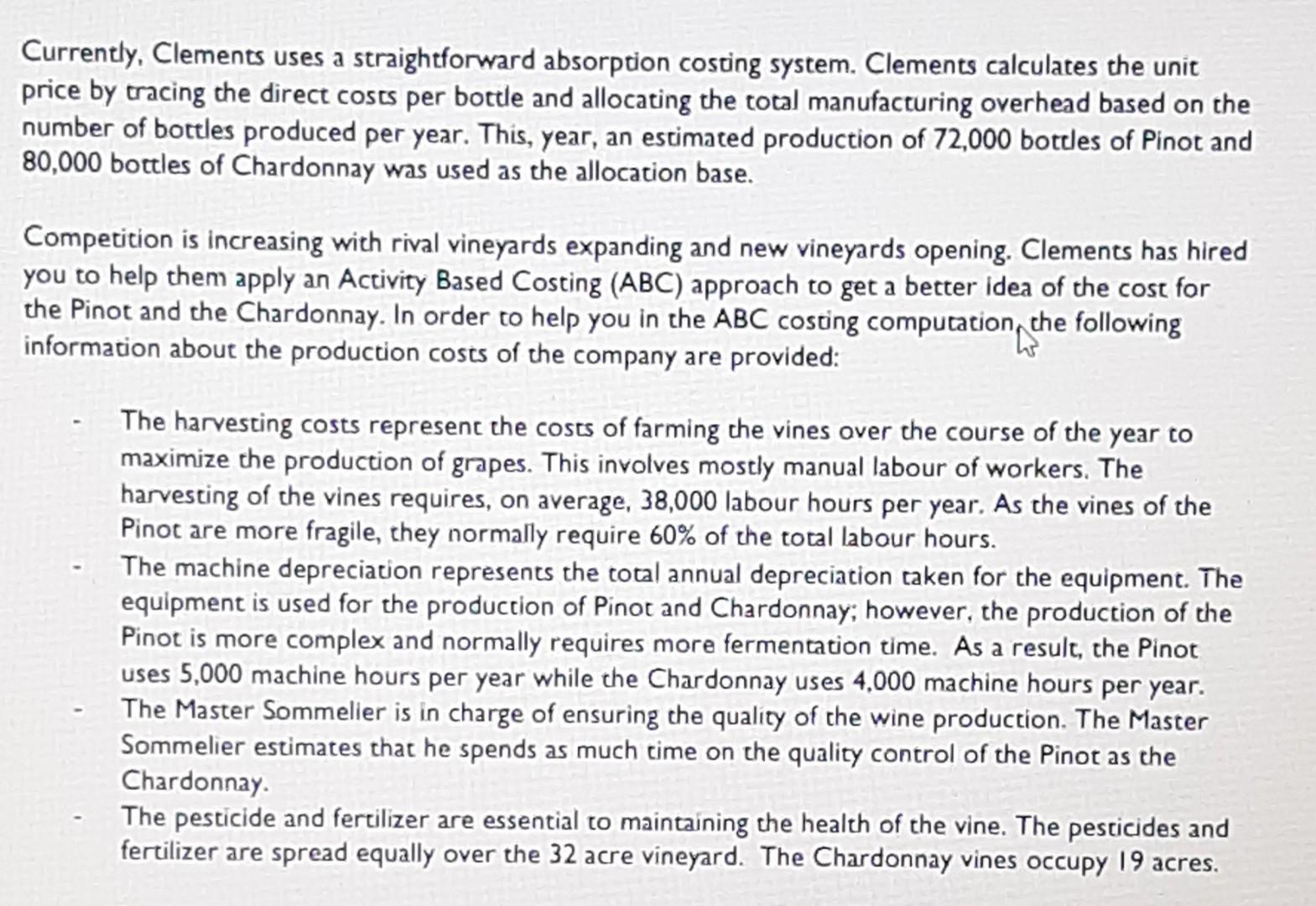

Clements vineyards ('Clements) is an independent wine producer located in the Niagara, Ontario region and is owned by Bertrand. Recently, management took the decision to restrict the product line and specialize in the production of two types of wine: Pinot and Chardonnay. The following information pertains to Clements' production. Pinot Direct Costs per bottle Grapes Bottle Direct Labour $ S S Chardonnay 3.00 $ 2.60 0.65 0.55 2.10 $ 2.00 The wine is usually produced in batches of 200 boules. The batch costs are the same to produce the Pinor and the Chardonnay. Costs that pertain to the production of a batch of wine are listed in the table below: 140.00 Costs per batch Set up Costs of Machinery Barrels Production Supervisor $ $ $ 450.00 80.00 The following costs represents the shared manufacturing costs to produce Chardonnay and Pinoc Production Costs of the Company Harvesting Costs S Machinery Depreciation $ Master Sommelier Salary S Pesticide & Fertilizer S 540,000 310,500 95,000 30,000 Currently, Clements uses a straightforward absorption costing system. Clements calculates the unit price by tracing the direct coses per bottle and allocating the total manufacturing overhead based on the number of bottles produced per year. This, year, an estimated production of 72,000 bottles of Pinot and 80,000 bottles of Chardonnay was used as the allocation base. Competition is increasing with rival vineyards expanding and new vineyards opening. Clements has hired you to help them apply an Activity Based Costing (ABC) approach to get a better idea of the cost for the Pinot and the Chardonnay. In order to help you in the ABC costing computation, the following information about the production costs of the company are provided: The harvesting costs represent the costs of farming the vines over the course of the year to maximize the production of grapes. This involves mostly manual labour of workers. The harvesting of the vines requires, on average, 38,000 labour hours per year. As the vines of the Pinot are more fragile, they normally require 60% of the total labour hours. The machine depreciation represents the total annual depreciation taken for the equipment. The equipment is used for the production of Pinot and Chardonnay; however, the production of the Pinot is more complex and normally requires more fermentation time. As a result, the Pinot uses 5,000 machine hours per year while the Chardonnay uses 4,000 machine hours per year. The Master Sommelier is in charge of ensuring the quality of the wine production. The Master Sommelier estimates that he spends as much time on the quality control of the Pinot as the Chardonnay The pesticide and fertilizer are essential to maintaining the health of the vine. The pesticides and fertilizer are spread equally over the 32 acre vineyard. The Chardonnay vines occupy 19 acres. Required: 1. Calculate the cost of a bottle of Pinot and Chardonnay using the current absorption costing system. 2. Calculate the cost of a bottle of Pinot and Chardonnay using an Activity Based Costing approach. 3. Based on the results obtained above, would you advise Bertrand to apply ABC costing? PART II Bertrand indicates that he pays $35,000 per year to enter the Pinot in various contests in an effort to win awards and pick-up accolades that can be displayed on the label of the bottle. This is a common practice for Pinot producers and most rival organizations also enter their Pinots in the same contests. This cost is specific to the Pinot. It allows them to charge a premium for their Pinot Bertrand believes that their Pinot would be at a serious disadvantage if they did not participate in these contests. Required: 1. Bertrand asks you if he could include this cost as part of the cost of the Pinot under the current costing system and/or under ABC Costing. Clements vineyards ('Clements) is an independent wine producer located in the Niagara, Ontario region and is owned by Bertrand. Recently, management took the decision to restrict the product line and specialize in the production of two types of wine: Pinot and Chardonnay. The following information pertains to Clements' production. Pinot Direct Costs per bottle Grapes Bottle Direct Labour $ S S Chardonnay 3.00 $ 2.60 0.65 0.55 2.10 $ 2.00 The wine is usually produced in batches of 200 boules. The batch costs are the same to produce the Pinor and the Chardonnay. Costs that pertain to the production of a batch of wine are listed in the table below: 140.00 Costs per batch Set up Costs of Machinery Barrels Production Supervisor $ $ $ 450.00 80.00 The following costs represents the shared manufacturing costs to produce Chardonnay and Pinoc Production Costs of the Company Harvesting Costs S Machinery Depreciation $ Master Sommelier Salary S Pesticide & Fertilizer S 540,000 310,500 95,000 30,000 Currently, Clements uses a straightforward absorption costing system. Clements calculates the unit price by tracing the direct coses per bottle and allocating the total manufacturing overhead based on the number of bottles produced per year. This, year, an estimated production of 72,000 bottles of Pinot and 80,000 bottles of Chardonnay was used as the allocation base. Competition is increasing with rival vineyards expanding and new vineyards opening. Clements has hired you to help them apply an Activity Based Costing (ABC) approach to get a better idea of the cost for the Pinot and the Chardonnay. In order to help you in the ABC costing computation, the following information about the production costs of the company are provided: The harvesting costs represent the costs of farming the vines over the course of the year to maximize the production of grapes. This involves mostly manual labour of workers. The harvesting of the vines requires, on average, 38,000 labour hours per year. As the vines of the Pinot are more fragile, they normally require 60% of the total labour hours. The machine depreciation represents the total annual depreciation taken for the equipment. The equipment is used for the production of Pinot and Chardonnay; however, the production of the Pinot is more complex and normally requires more fermentation time. As a result, the Pinot uses 5,000 machine hours per year while the Chardonnay uses 4,000 machine hours per year. The Master Sommelier is in charge of ensuring the quality of the wine production. The Master Sommelier estimates that he spends as much time on the quality control of the Pinot as the Chardonnay The pesticide and fertilizer are essential to maintaining the health of the vine. The pesticides and fertilizer are spread equally over the 32 acre vineyard. The Chardonnay vines occupy 19 acres. Required: 1. Calculate the cost of a bottle of Pinot and Chardonnay using the current absorption costing system. 2. Calculate the cost of a bottle of Pinot and Chardonnay using an Activity Based Costing approach. 3. Based on the results obtained above, would you advise Bertrand to apply ABC costing? PART II Bertrand indicates that he pays $35,000 per year to enter the Pinot in various contests in an effort to win awards and pick-up accolades that can be displayed on the label of the bottle. This is a common practice for Pinot producers and most rival organizations also enter their Pinots in the same contests. This cost is specific to the Pinot. It allows them to charge a premium for their Pinot Bertrand believes that their Pinot would be at a serious disadvantage if they did not participate in these contests. Required: 1. Bertrand asks you if he could include this cost as part of the cost of the Pinot under the current costing system and/or under ABC CostingStep by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started