Can someone help me solve by showing all work and explaining background information?

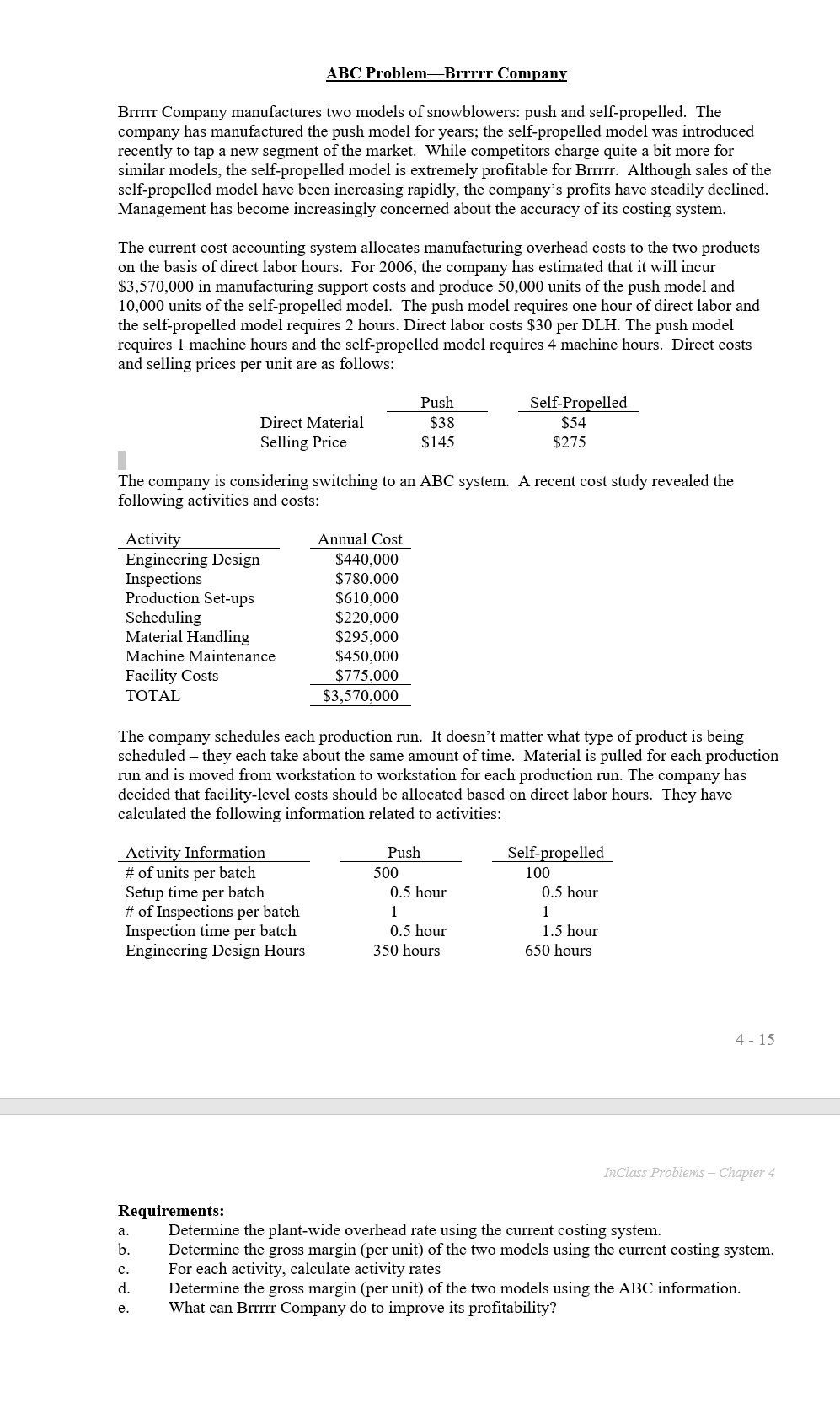

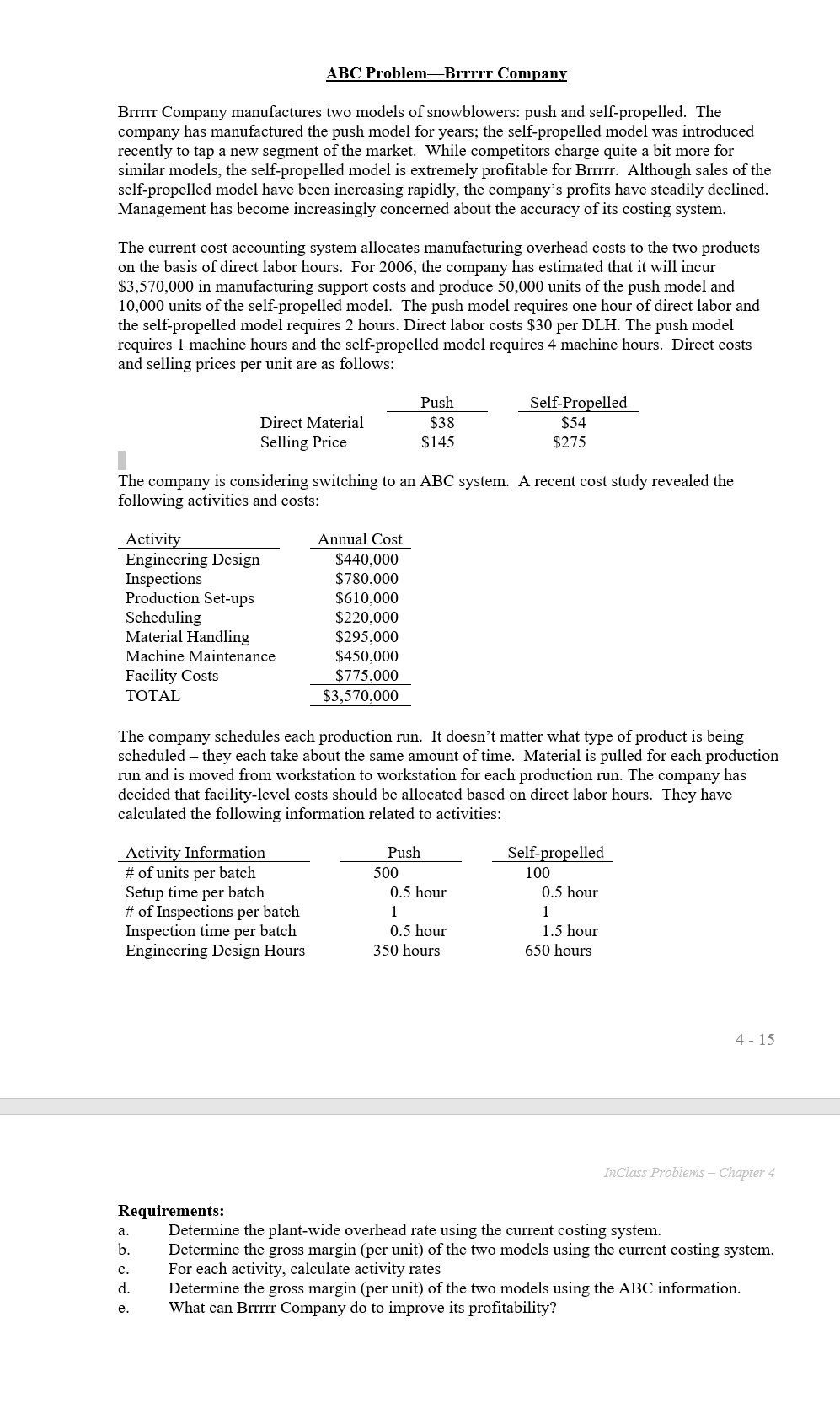

ABC ProblemBrrrrr Company Brrrrr Company manufactures two models of snowblowers: push and self-propelled. The company has manufactured the push model for years; the self-propelled model was introduced recently to tap a new segment of the market. While competitors charge quite a bit more for similar models, the self-propelled model is extremely profitable for Brrrrr. Although sales of the self-propelled model have been increasing rapidly, the company's profits have steadily declined. Management has become increasingly concerned about the accuracy of its costing system. The current cost accounting system allocates manufacturing overhead costs to the two products on the basis of direct labor hours. For 2006, the company has estimated that it will incur $3,570,000 in manufacturing support costs and produce 50,000 units of the push model and 10,000 units of the self-propelled model. The push model requires one hour of direct labor and the self-propelled model requires 2 hours. Direct labor costs $30 per DLH. The push model requires 1 machine hours and the self-propelled model requires 4 machine hours. Direct costs and selling prices per unit are as follows: Direct Material Selling Price Push $38 $145 Self-Propelled $54 $275 The company is considering switching to an ABC system. A recent cost study revealed the following activities and costs: Activity Engineering Design Inspections Production Set-ups Scheduling Material Handling Machine Maintenance Facility Costs TOTAL Annual Cost $440,000 $780,000 $610,000 $220,000 $295,000 $450,000 $775,000 $3,570,000 The company schedules each tion run. It doesn't atter what type of product is being scheduled - they each take about the same amount of time. Material is pulled for each production run and is moved from workstation to workstation for each production run. The company has decided that facility-level costs should be allocated based on direct labor hours. They have calculated the following information related to activities: Activity Information # of units per batch Setup time per batch # of Inspections per batch Inspection time per batch Engineering Design Hours Push 500 0.5 hour 1 0.5 hour 350 hours Self-propelled 100 0.5 hour 1 1.5 hour 650 hours 4 - 15 InClass Problems - Chapter 4 Requirements: a. Determine the plant-wide overhead rate using the current costing system. b. Determine the gross margin (per unit) of the two models using the current costing system. For each activity, calculate activity rates Determine the gross margin (per unit) of the two models using the ABC information. What can Brrrrr Company do to improve its profitability? c. d. e