Question

Case 14 Northern Gushers Northern Gushers Drilling has developed a lease on the North Slope of Alaska over the last five years. They have drilled

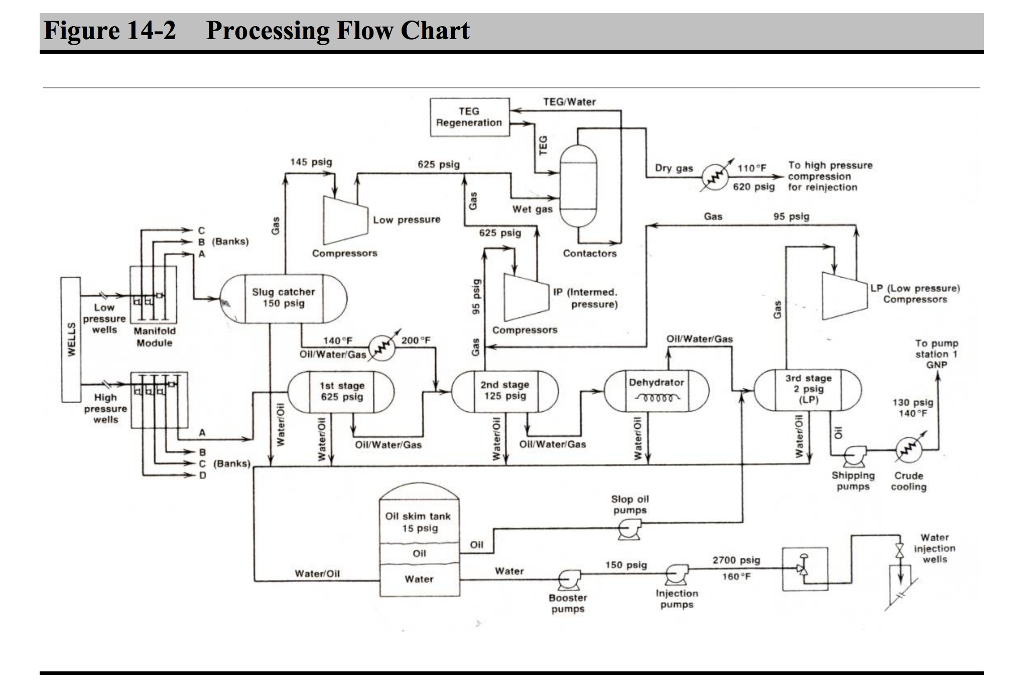

Case 14 Northern Gushers Northern Gushers Drilling has developed a lease on the North Slope of Alaska over the last five years. They have drilled 16 production wells evenly spaced over the four square miles of the lease tract. Every wells production declines over time, so to maintain a steady total flow new wells are drilled. Specifically, total production from the existing wells will decline at 17% per year if no new wells are drilled. All wells have been directionally drilled from the gravel drill pad, which also contains a processing facility (see Figure 14-1). Figure 14-1 Field Arrangement Case 14 Northern Gushers 91 This processing facility separates water and natural gas from the crude oil stream. By reducing the pressure from formation to atmospheric levels, the volatile gases are removed from the oil. The oil is then dehydrated to remove water before transfer to the pipeline. As shown in the flowchart of Figure 14-2, a small portion of the natural gas is used to power the facility. Then most of the natural gas and all the water are repressurized and reinjected into the formation. This reinjection avoids the environmental problems of flaring the gas or surface disposal of contaminated water. It also helps maintain the pressure in the oil formation to increase total recovery. Figure 14-2 Processing Flow Chart The timing of new wells has been planned to maintain a steady flow of about 20,000 barrels of oil per day (BOPD). This flow rate is the shipping space on the Great Northern Pipeline that has been allotted to Northern Gushers parent company. Fluctuations in Cases in Engineering Economy 2nd by Peterson & Eschenbach 92 production are matched with the shipping space by buying, selling, and trading with other shippers at about the tariffs cost per barrel. A second consideration has been maximizing total recovery by distributing new wells over the leased tract. Thus, each of the 16 wells has helped maintain current production and also increased total recovery from the field. Now Northern Gusher is facing a different problem. The entire leased tract has been covered by the 16 wells. New wells will be drilled in-between existing wells and will therefore have less impact on total recovery from the field. Each new well will increase production now by 2000 BOPD and increase the decline rate by 1%. Since each well costs about $2 million to drill and $1.75 million to tie into the production facilities, the management of Northern Gushers must justify this decision to their parent company by identifying the rate of return on the required capital investment. Additional capital is required every 7 years to do a well work-over for $1.25 million. Abandonment costs in the final year of production amount to 10% of the initial drilling and facility costs. The abandonment costs are required by state agencies to return the land to its initial condition. Currently, the tariff for transportation through the pipeline is $5.25 per barrel, and another $3.75 per barrel is required to ship it to market. The incremental annual operating and maintenance cost for the field is $200,000 for each new well. At this point, Northern Gusher must decide whether to initiate planning and construction for Well 17. This particular well could come on line next year with an estimated production rate of 2000 BOPD once tied into existing separation facilities. By next year, Northern Gushers total production rate will fall to 18,000 BOPD. The production of the 16 wells is declining at 17% per year. With the new well added in, the higher production rate results in a field decline rate that is 1% higher at 18% per year. For simplification, the new decline rate can be assumed to begin as soon as the new well is drilled since the field will be producing at a higher rate almost from the start. While more wells will be drilled in the future, economic analysis of Well 17 is done without considering them. Oil production at the facility will be closed down (the field will be shut-in) when the total field production reaches 500 BOPD. At that production rate, it is no longer economic to operate the field. Because some of the oil produced by Well 17 would have been produced in later years by nearby wells, the incremental production rate with Well 17 versus without Well 17 will be negative in later years. This sign change in the cash flows can result in multiple rates of return, so that is an additional concern of management. The value of oil has varied dramatically over the last six years, from a low of $18 per barrel to a high of $140 per barrel, back down to $22 per barrel and then back up to the Case 14 Northern Gushers 93 current level of $45 per barrel. Because of this vast uncertainty, your boss has given you guidelines of $30 per barrel and a horizon of 20 years for the initial analysis. Should Well 17 be added now, and how much additional oil will be produced? What is the incremental rate of return on this investment? Options 1. If management demands an internal rate of return of 15% on investments, can Well 17 be justified now or at a later date? If now, when can well 18, 19, and so on be justified? Each of these later wells will have a similar effect on the total decline rate for the field. Specifically, assume that each well increases the decline rate by 1%. 2. Rather than considering the price of oil to be fixed at its current level, consider the impact of a higher or lower inflation rate for oil than for the economy as a whole.

Case 14 Northern Gushers Northern Gushers Drilling has developed a lease on the North Slope of Alaska over the last five years. They have drilled 16 production wells evenly spaced over the four square miles of the lease tract. Every wells production declines over time, so to maintain a steady total flow new wells are drilled. Specifically, total production from the existing wells will decline at 17% per year if no new wells are drilled. All wells have been directionally drilled from the gravel drill pad, which also contains a processing facility (see Figure 14-1). Figure 14-1 Field Arrangement Case 14 Northern Gushers 91 This processing facility separates water and natural gas from the crude oil stream. By reducing the pressure from formation to atmospheric levels, the volatile gases are removed from the oil. The oil is then dehydrated to remove water before transfer to the pipeline. As shown in the flowchart of Figure 14-2, a small portion of the natural gas is used to power the facility. Then most of the natural gas and all the water are repressurized and reinjected into the formation. This reinjection avoids the environmental problems of flaring the gas or surface disposal of contaminated water. It also helps maintain the pressure in the oil formation to increase total recovery. Figure 14-2 Processing Flow Chart The timing of new wells has been planned to maintain a steady flow of about 20,000 barrels of oil per day (BOPD). This flow rate is the shipping space on the Great Northern Pipeline that has been allotted to Northern Gushers parent company. Fluctuations in Cases in Engineering Economy 2nd by Peterson & Eschenbach 92 production are matched with the shipping space by buying, selling, and trading with other shippers at about the tariffs cost per barrel. A second consideration has been maximizing total recovery by distributing new wells over the leased tract. Thus, each of the 16 wells has helped maintain current production and also increased total recovery from the field. Now Northern Gusher is facing a different problem. The entire leased tract has been covered by the 16 wells. New wells will be drilled in-between existing wells and will therefore have less impact on total recovery from the field. Each new well will increase production now by 2000 BOPD and increase the decline rate by 1%. Since each well costs about $2 million to drill and $1.75 million to tie into the production facilities, the management of Northern Gushers must justify this decision to their parent company by identifying the rate of return on the required capital investment. Additional capital is required every 7 years to do a well work-over for $1.25 million. Abandonment costs in the final year of production amount to 10% of the initial drilling and facility costs. The abandonment costs are required by state agencies to return the land to its initial condition. Currently, the tariff for transportation through the pipeline is $5.25 per barrel, and another $3.75 per barrel is required to ship it to market. The incremental annual operating and maintenance cost for the field is $200,000 for each new well. At this point, Northern Gusher must decide whether to initiate planning and construction for Well 17. This particular well could come on line next year with an estimated production rate of 2000 BOPD once tied into existing separation facilities. By next year, Northern Gushers total production rate will fall to 18,000 BOPD. The production of the 16 wells is declining at 17% per year. With the new well added in, the higher production rate results in a field decline rate that is 1% higher at 18% per year. For simplification, the new decline rate can be assumed to begin as soon as the new well is drilled since the field will be producing at a higher rate almost from the start. While more wells will be drilled in the future, economic analysis of Well 17 is done without considering them. Oil production at the facility will be closed down (the field will be shut-in) when the total field production reaches 500 BOPD. At that production rate, it is no longer economic to operate the field. Because some of the oil produced by Well 17 would have been produced in later years by nearby wells, the incremental production rate with Well 17 versus without Well 17 will be negative in later years. This sign change in the cash flows can result in multiple rates of return, so that is an additional concern of management. The value of oil has varied dramatically over the last six years, from a low of $18 per barrel to a high of $140 per barrel, back down to $22 per barrel and then back up to the Case 14 Northern Gushers 93 current level of $45 per barrel. Because of this vast uncertainty, your boss has given you guidelines of $30 per barrel and a horizon of 20 years for the initial analysis. Should Well 17 be added now, and how much additional oil will be produced? What is the incremental rate of return on this investment? Options 1. If management demands an internal rate of return of 15% on investments, can Well 17 be justified now or at a later date? If now, when can well 18, 19, and so on be justified? Each of these later wells will have a similar effect on the total decline rate for the field. Specifically, assume that each well increases the decline rate by 1%. 2. Rather than considering the price of oil to be fixed at its current level, consider the impact of a higher or lower inflation rate for oil than for the economy as a whole.

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started