Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Case 4.1 Cases CASE 4.1 LANDRY ASSOCIATES CAPACITY ANALYSIS. Landry Associates produces a broad range of components for stereos and similar electronic products. It has

Case 4.1

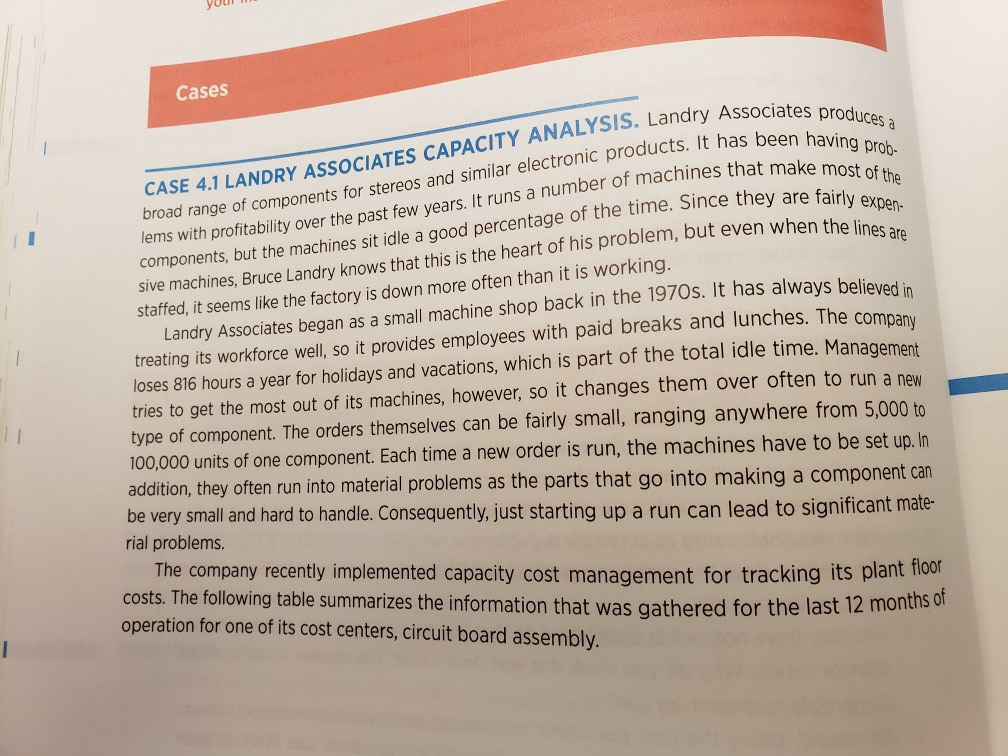

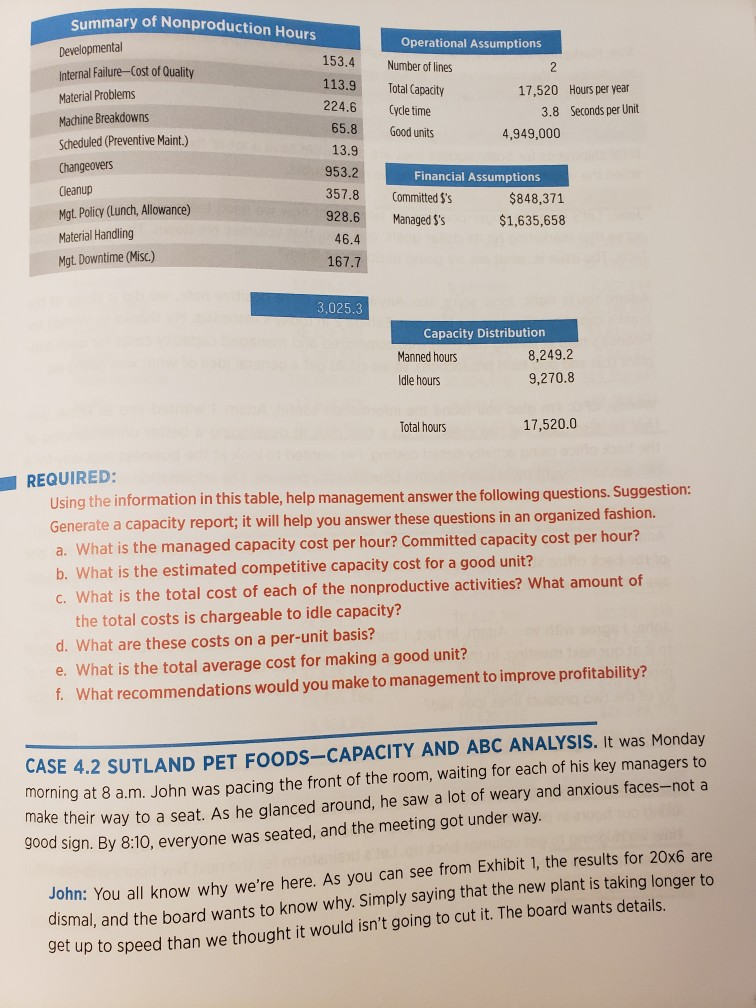

Cases CASE 4.1 LANDRY ASSOCIATES CAPACITY ANALYSIS. Landry Associates produces a broad range of components for stereos and similar electronic products. It has been having prob- lems with profitability over the past few years. It runs a number of machines that make most of the components, but the machines sit idle a good percentage of the time. Since they are fairly expen- sive machines, Bruce Landry knows that this is the heart of his problem, but even when the lines are staffed, it seems like the factory is down more often than it is working. Landry Associates began as a small machine shop back in the 1970s. It has always believed in treating its workforce well, so it provides employees with paid breaks and lunches. The company loses 816 hours a year for holidays and vacations, which is part of the total idle time. Management tries to get the most out of its machines, however, so it changes them over often to run a new type of component. The orders themselves can be fairly small, ranging anywhere from 5,000 to 100,000 units of one component. Each time a new order is run, the machines have to be set up. In addition, they often run into material problems as the parts that go into making a component can be very small and hard to handle. Consequently, just starting up a run can lead to significant mate- rial problems. The company recently implemented capacity cost management for tracking its plant floor costs. The following table summarizes the information that was gathered for the last 12 months of operation for one of its cost centers, circuit board assembly. Summary of Nonproduction Hours Operational Asumptions Developmental 153,4 Number of lines 2 Internal Failure-Cost of Quality 113.9 Total Capacity Hours per year 17,520 Material Problems 224.6 Cycle time Seconds per Unit 3.8 Machine Breakdowns 65.8 Good units 4,949,000 Scheduled (Preventive Maint.) 13.9 Changeovers 953.2 Financial Assumptions Cleanup 357,8 Committed $'s $848,371 Mat. Policy (Lunch, Allowance) 928.6 Managed $'s $1,635,658 Material Handling 46,4 Mgt. Downtime (Misc.) 167.7 3,025,3 Capacity Distribution 8,249.2 Manned hours 9,270.8 Idle hours 17,520.0 Total hours REQUIRED: Using the information in this table, help management answer the following questions. Suggestion: Generate a capacity report; it will help you answer these questions in an organized fashion. a. What is the managed capacity cost per hour? Committed capacity cost per hour? b. What is the estimated competitive capacity cost for a good unit? c.What is the total cost of each of the nonproductive activities? What amount of the total costs is chargeable to idle capacity? d.What are these costs on a per-unit basis? e. What is the total average cost for making a good unit? f. What recommendations would you make to management to improve profitability? CASE 4.2 SUTLAND PET FOODS-CAPACITY AND ABC ANALYSIS. It was Monday make their way to a seat. As he glanced around, he saw a lot of weary and anxious faces-not a good sign. By 8:10, everyone was seated, and the meeting got under way. morning at 8 a.m. John was pacing the front of the room, waiting for each of his key managers to John: You all know why we're here. As you can see from Exhibit 1, the results for 20x6 are dismal, and the board wants to know why. Simply saying that the new plant is taking longer to get up to speed than we thought it would isn't going to cut it. The board wants details Cases CASE 4.1 LANDRY ASSOCIATES CAPACITY ANALYSIS. Landry Associates produces a broad range of components for stereos and similar electronic products. It has been having prob- lems with profitability over the past few years. It runs a number of machines that make most of the components, but the machines sit idle a good percentage of the time. Since they are fairly expen- sive machines, Bruce Landry knows that this is the heart of his problem, but even when the lines are staffed, it seems like the factory is down more often than it is working. Landry Associates began as a small machine shop back in the 1970s. It has always believed in treating its workforce well, so it provides employees with paid breaks and lunches. The company loses 816 hours a year for holidays and vacations, which is part of the total idle time. Management tries to get the most out of its machines, however, so it changes them over often to run a new type of component. The orders themselves can be fairly small, ranging anywhere from 5,000 to 100,000 units of one component. Each time a new order is run, the machines have to be set up. In addition, they often run into material problems as the parts that go into making a component can be very small and hard to handle. Consequently, just starting up a run can lead to significant mate- rial problems. The company recently implemented capacity cost management for tracking its plant floor costs. The following table summarizes the information that was gathered for the last 12 months of operation for one of its cost centers, circuit board assembly. Summary of Nonproduction Hours Operational Asumptions Developmental 153,4 Number of lines 2 Internal Failure-Cost of Quality 113.9 Total Capacity Hours per year 17,520 Material Problems 224.6 Cycle time Seconds per Unit 3.8 Machine Breakdowns 65.8 Good units 4,949,000 Scheduled (Preventive Maint.) 13.9 Changeovers 953.2 Financial Assumptions Cleanup 357,8 Committed $'s $848,371 Mat. Policy (Lunch, Allowance) 928.6 Managed $'s $1,635,658 Material Handling 46,4 Mgt. Downtime (Misc.) 167.7 3,025,3 Capacity Distribution 8,249.2 Manned hours 9,270.8 Idle hours 17,520.0 Total hours REQUIRED: Using the information in this table, help management answer the following questions. Suggestion: Generate a capacity report; it will help you answer these questions in an organized fashion. a. What is the managed capacity cost per hour? Committed capacity cost per hour? b. What is the estimated competitive capacity cost for a good unit? c.What is the total cost of each of the nonproductive activities? What amount of the total costs is chargeable to idle capacity? d.What are these costs on a per-unit basis? e. What is the total average cost for making a good unit? f. What recommendations would you make to management to improve profitability? CASE 4.2 SUTLAND PET FOODS-CAPACITY AND ABC ANALYSIS. It was Monday make their way to a seat. As he glanced around, he saw a lot of weary and anxious faces-not a good sign. By 8:10, everyone was seated, and the meeting got under way. morning at 8 a.m. John was pacing the front of the room, waiting for each of his key managers to John: You all know why we're here. As you can see from Exhibit 1, the results for 20x6 are dismal, and the board wants to know why. Simply saying that the new plant is taking longer to get up to speed than we thought it would isn't going to cut it. The board wants detailsStep by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started