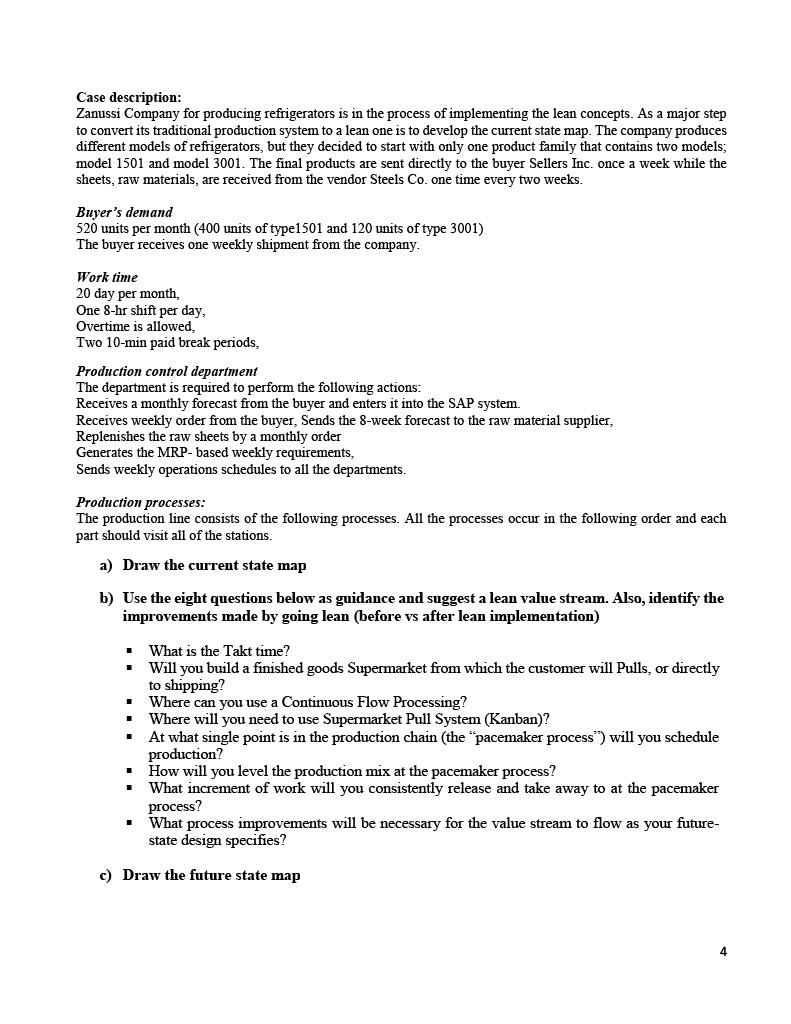

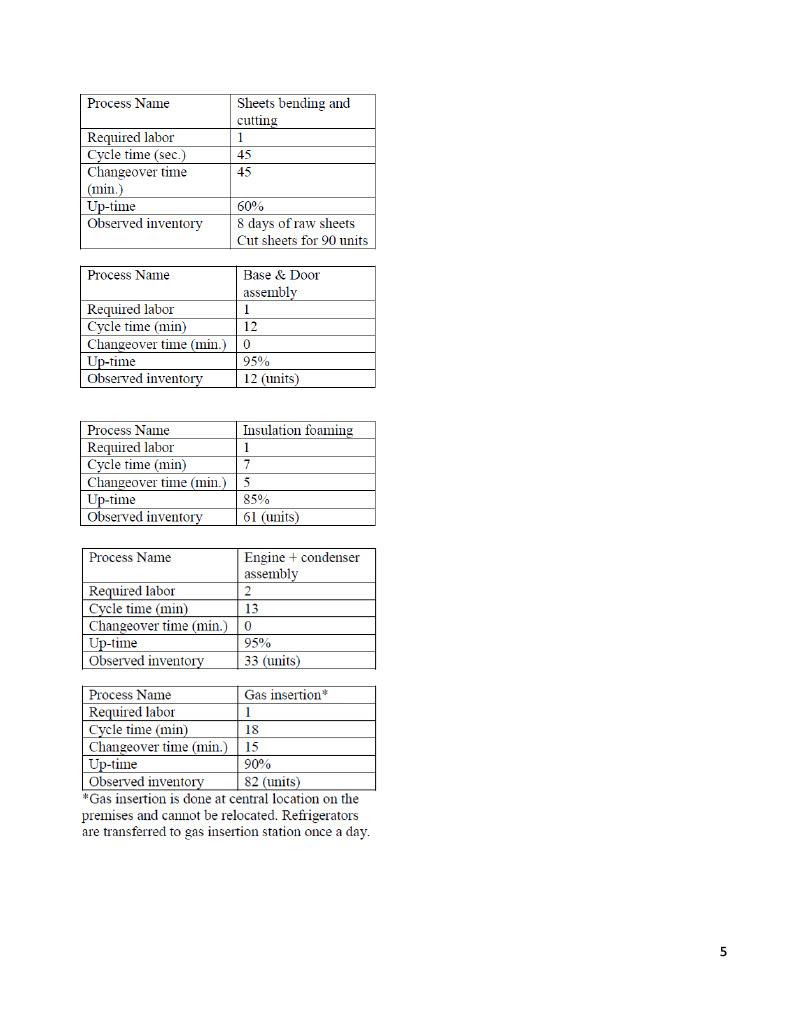

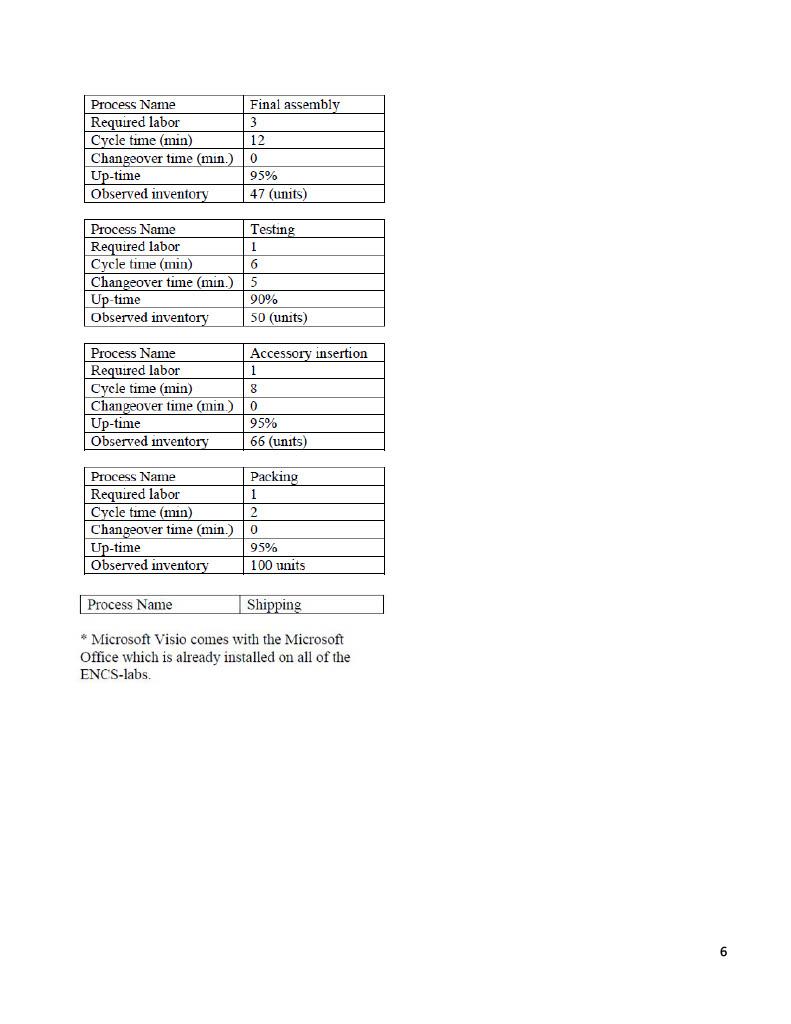

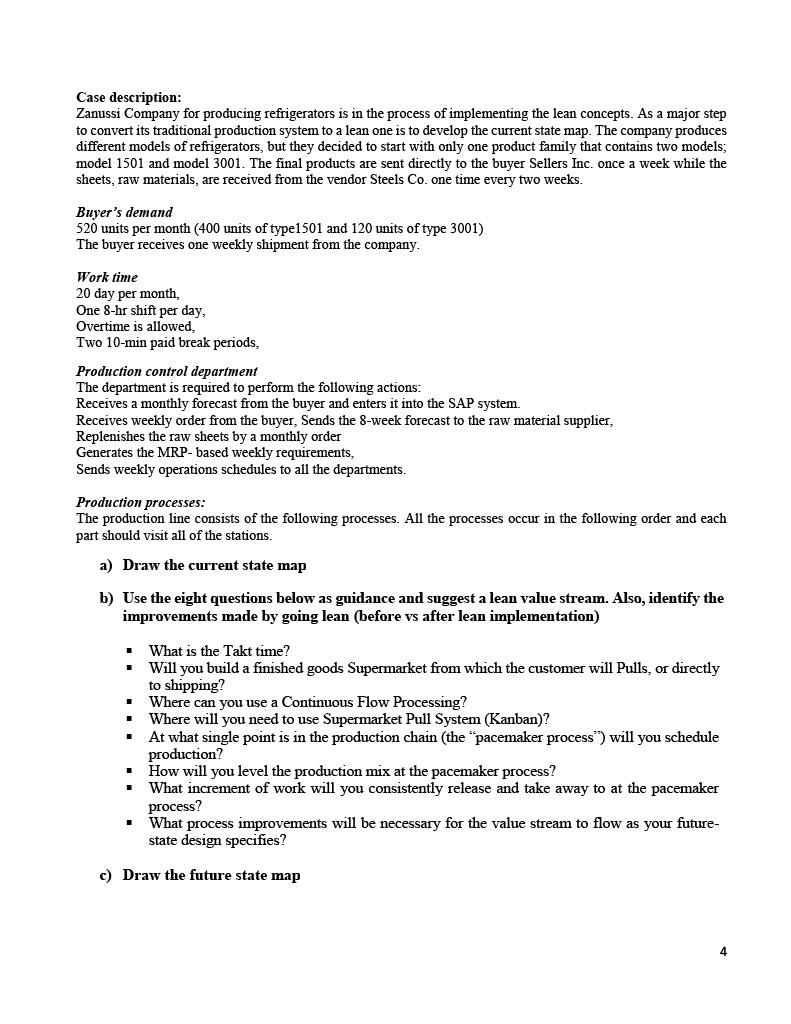

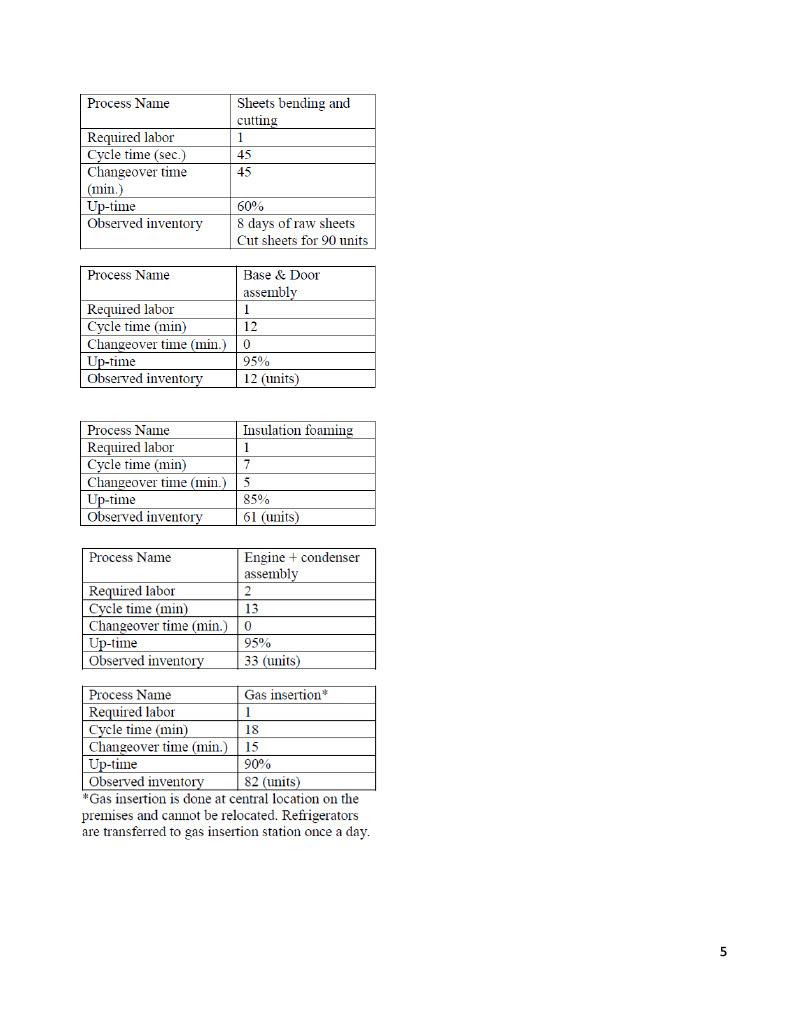

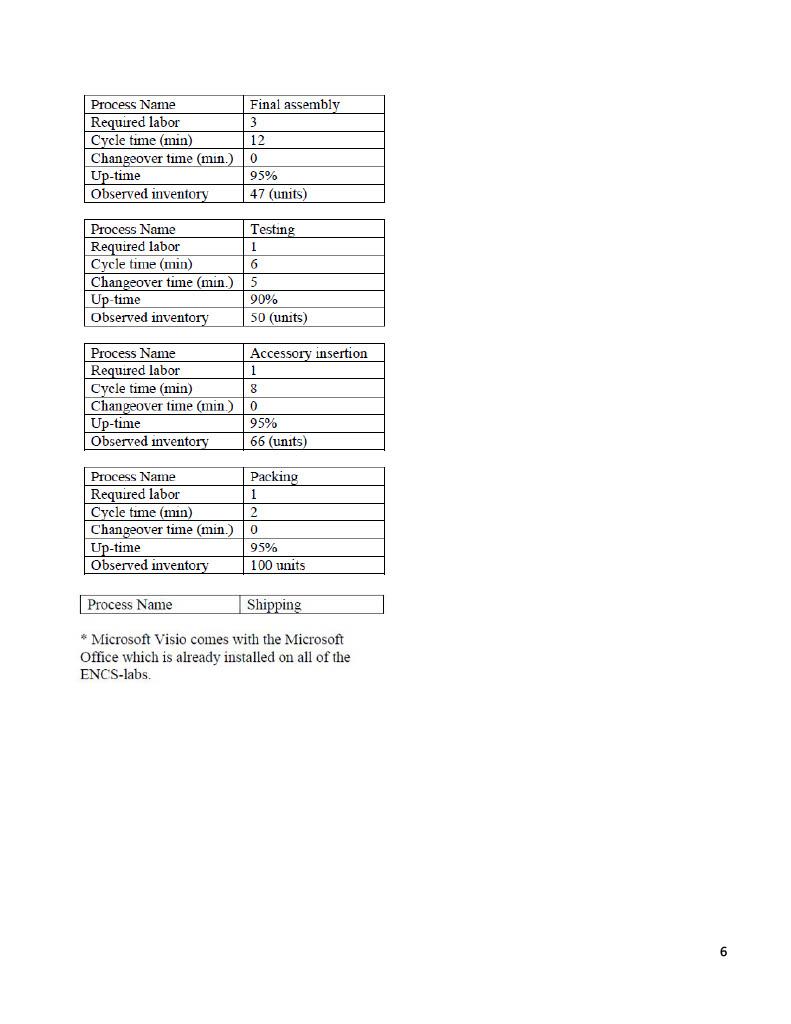

Case description: Zanussi Company for producing refrigerators is in the process of implementing the lean concepts. As a major step to convert its traditional production system to a lean one is to develop the current state map. The company produces different models of refrigerators, but they decided to start with only one product family that contains two models; model 1501 and model 3001 . The final products are sent directly to the buyer Sellers Inc. once a week while the sheets, raw materials, are received from the vendor Steels Co. one time every two weeks. Buyer's demand 520 units per month ( 400 units of type 1501 and 120 units of type 3001 ) The buyer receives one weekly shipment from the company. Work time 20 day per month, One 8-hr shift per day, Overtime is allowed, Two 10 -min paid break periods, Production control department The department is required to perform the following actions: Receives a monthly forecast from the buyer and enters it into the SAP system. Receives weekly order from the buyer, Sends the 8-week forecast to the raw material supplier, Replenishes the raw sheets by a monthly order Generates the MRP- based weekly requirements, Sends weekly operations schedules to all the departments. Production processes: The production line consists of the following processes. All the processes occur in the following order and each part should visit all of the stations. a) Draw the current state map b) Use the eight questions below as guidance and suggest a lean value stream. Also, identify the improvements made by going lean (before vs after lean implementation) - What is the Takt time? - Will you build a finished goods Supermarket from which the customer will Pulls, or directly to shipping? - Where can you use a Continuous Flow Processing? - Where will you need to use Supermarket Pull System (Kanban)? - At what single point is in the production chain (the "pacemaker process") will you schedule production? - How will you level the production mix at the pacemaker process? - What increment of work will you consistently release and take away to at the pacemaker process? - What process improvements will be necessary for the value stream to flow as your futurestate design specifies? c) Draw the future state map FGas insertion is done at central location on the premises and cannot be relocated. Refrigerators are transferred to gas insertion station once a day. * Microsoft Visio comes with the Microsoft Office which is already installed on all of the ENC S-labs. Case description: Zanussi Company for producing refrigerators is in the process of implementing the lean concepts. As a major step to convert its traditional production system to a lean one is to develop the current state map. The company produces different models of refrigerators, but they decided to start with only one product family that contains two models; model 1501 and model 3001 . The final products are sent directly to the buyer Sellers Inc. once a week while the sheets, raw materials, are received from the vendor Steels Co. one time every two weeks. Buyer's demand 520 units per month ( 400 units of type 1501 and 120 units of type 3001 ) The buyer receives one weekly shipment from the company. Work time 20 day per month, One 8-hr shift per day, Overtime is allowed, Two 10 -min paid break periods, Production control department The department is required to perform the following actions: Receives a monthly forecast from the buyer and enters it into the SAP system. Receives weekly order from the buyer, Sends the 8-week forecast to the raw material supplier, Replenishes the raw sheets by a monthly order Generates the MRP- based weekly requirements, Sends weekly operations schedules to all the departments. Production processes: The production line consists of the following processes. All the processes occur in the following order and each part should visit all of the stations. a) Draw the current state map b) Use the eight questions below as guidance and suggest a lean value stream. Also, identify the improvements made by going lean (before vs after lean implementation) - What is the Takt time? - Will you build a finished goods Supermarket from which the customer will Pulls, or directly to shipping? - Where can you use a Continuous Flow Processing? - Where will you need to use Supermarket Pull System (Kanban)? - At what single point is in the production chain (the "pacemaker process") will you schedule production? - How will you level the production mix at the pacemaker process? - What increment of work will you consistently release and take away to at the pacemaker process? - What process improvements will be necessary for the value stream to flow as your futurestate design specifies? c) Draw the future state map FGas insertion is done at central location on the premises and cannot be relocated. Refrigerators are transferred to gas insertion station once a day. * Microsoft Visio comes with the Microsoft Office which is already installed on all of the ENC S-labs