Question

Chairvana Inc. manufactures metal tables and chairs at its plant in Paxton, Illinois. Recently hired general manager, Bob Behar, is concerned about the large inventories

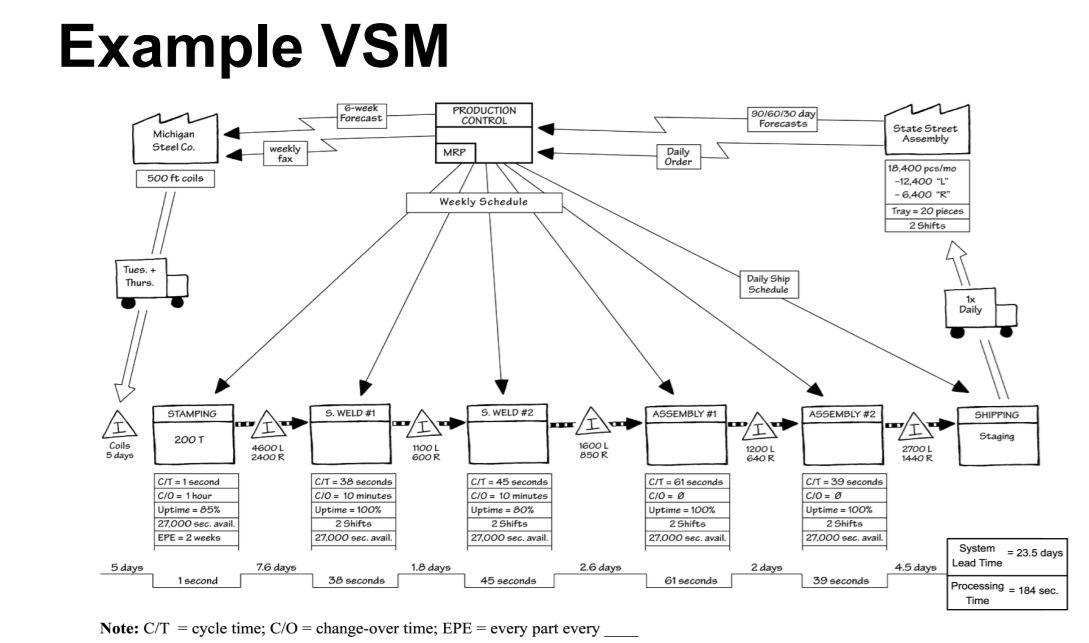

Chairvana Inc. manufactures metal tables and chairs at its plant in Paxton, Illinois. Recently hired general manager, Bob Behar, is concerned about the large inventories and manufacturing inefficiencies in the plant.The Paxton plant has two separate assembly lines - one for chairs and one for tables. Demand for chairs is significantly larger than tables, so Bob decides to tackle the table assembly process first. Bob has recently hired a summer intern, Eileen Mayer, who he asks to study the table assembly line and suggest ways to improve the process. Having recently completed a course on operations management, Eileen decides to make a value stream map for the process. Over a period of several days she collects the following information about the process.

The Assembly Line: The assembly line operates one 8-hour shift per day, 5 days a week.

The Product: Chairvana makes one type of folding table. The table has two bent metal tubes that form the legs, and a formed sheet-metal top.

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started