Answered step by step

Verified Expert Solution

Question

1 Approved Answer

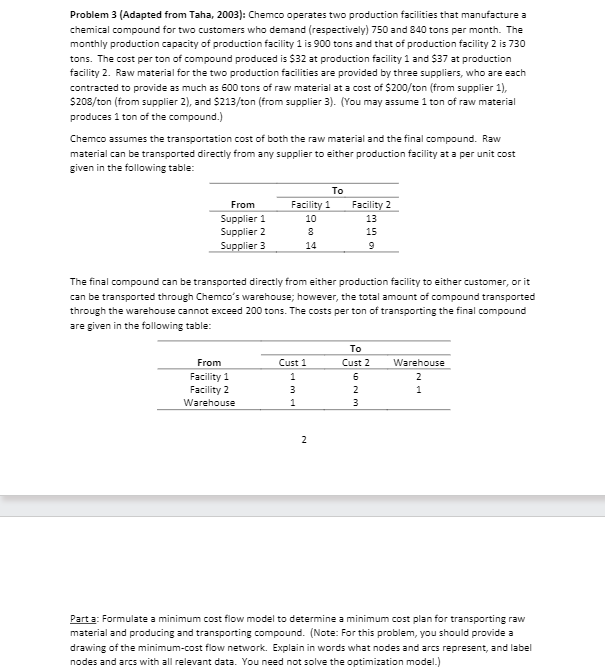

Chemco operates two production facilities that manufacture achemical compound for two customers who demand ( respectively ) 7 5 0 and 8 4 0 tons

Chemco operates two production facilities that manufacture achemical compound for two customers who demand respectively and tons per month. Themonthly production capacity of production facility is tons and that of production facility is tons. The cost per ton of compound produced is $ at production facility and $ at productionfacility Raw material for the two production facilities are provided by three suppliers, who are eachcontracted to provide as much as tons of raw material at a cost of $ton from supplier $ton from supplier and $ton from supplier You may assume ton of raw materialproduces ton of the compound.Chemco assumes the transportation cost of both the raw material and the final compound. Rawmaterial can be transported directly from any supplier to either production facility at a per unit costgiven in the following table:ToFrom Facility Facility Supplier Supplier Supplier The final compound can be transported directly from either production facility to either customer, or itcan be transported through Chemcos warehouse; however, the total amount of compound transportedthrough the warehouse cannot exceed tons. The costs per ton of transporting the final compoundare given in the following table:ToFrom Cust Cust WarehouseFacility Facility Warehouse

Part a: Formulate a minimum cost flow model to determine a minimum cost plan for transporting rawmaterial and producing and transporting compound. Note: For this problem, you should provide adrawing of the minimumcost flow network. Explain in words what nodes and arcs represent, and labelnodes and arcs with all relevant data. You need not solve the optimization modelProblem Adapted from Taha, : Chemco operates two production facilities that manufacture a

chemical compound for two customers who demand respectively and tons per month. The

monthly production capacity of production facility is tons and that of production facility is

tons. The cost per ton of compound produced is $ at production facility and $ at production

facility Raw material for the two production facilities are provided by three suppliers, who are each

contracted to provide as much as tons of raw material at a cost of $ ton from supplier

$ ton from supplier and $ ton from supplier You may assume ton of raw material

produces ton of the compound.

Chemco assumes the transportation cost of both the raw material and the final compound. Raw

material can be transported directly from any supplier to either production facility at a per unit cost

given in the following table:

The final compound can be transported directly from either production facility to either customer, or it

can be transported through Chemco's warehouse; however, the total amount of compound transported

through the warehouse cannot exceed tons. The costs per ton of transporting the final compound

are given in the following table:

Part a: Formulate a minimum cost flow model to determine a minimum cost plan for transporting raw

material and producing and transporting compound. Note: For this problem, you should provide a

drawing of the minimumcost flow network. Explain in words what nodes and arcs represent, and label

nodes and arcs with all relevant data. You need not solve the optimization model.Problem Adapted from Taha, : Chemco operates two production facilities that manufacture a

chemical compound for two customers who demand respectively and tons per month. The

monthly production capacity of production facility is tons and that of production facility is

tons. The cost per ton of compound produced is $ at production facility and $ at production

facility Raw material for the two production facilities are provided by three suppliers, who are each

contracted to provide as much as tons of raw material at a cost of $ ton from supplier

$ ton from supplier and $ ton from supplier You may assume ton of raw material

produces ton of the compound.

Chemco assumes the transportation cost of both the raw material and the final compound. Raw

material can be transported directly from any supplier to either production facility at a per unit cost

given in the following table:

The final compound can be transported directly from either production facility to either customer, or it

can be transported through Chemco's warehouse; however, the total amount of compound transported

through the warehouse cannot exceed tons. The costs per ton of transporting the final compound

are given in the following table:

Part a: Formulate a minimum cost flow model to determine a minimum cost plan for transporting raw

materia

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started