Answered step by step

Verified Expert Solution

Question

1 Approved Answer

CLO covered: K1.1 Describe the role of inventory and warehouse management in logistics and business. With over 40 years' heritage, Comfy Quilts has grown to

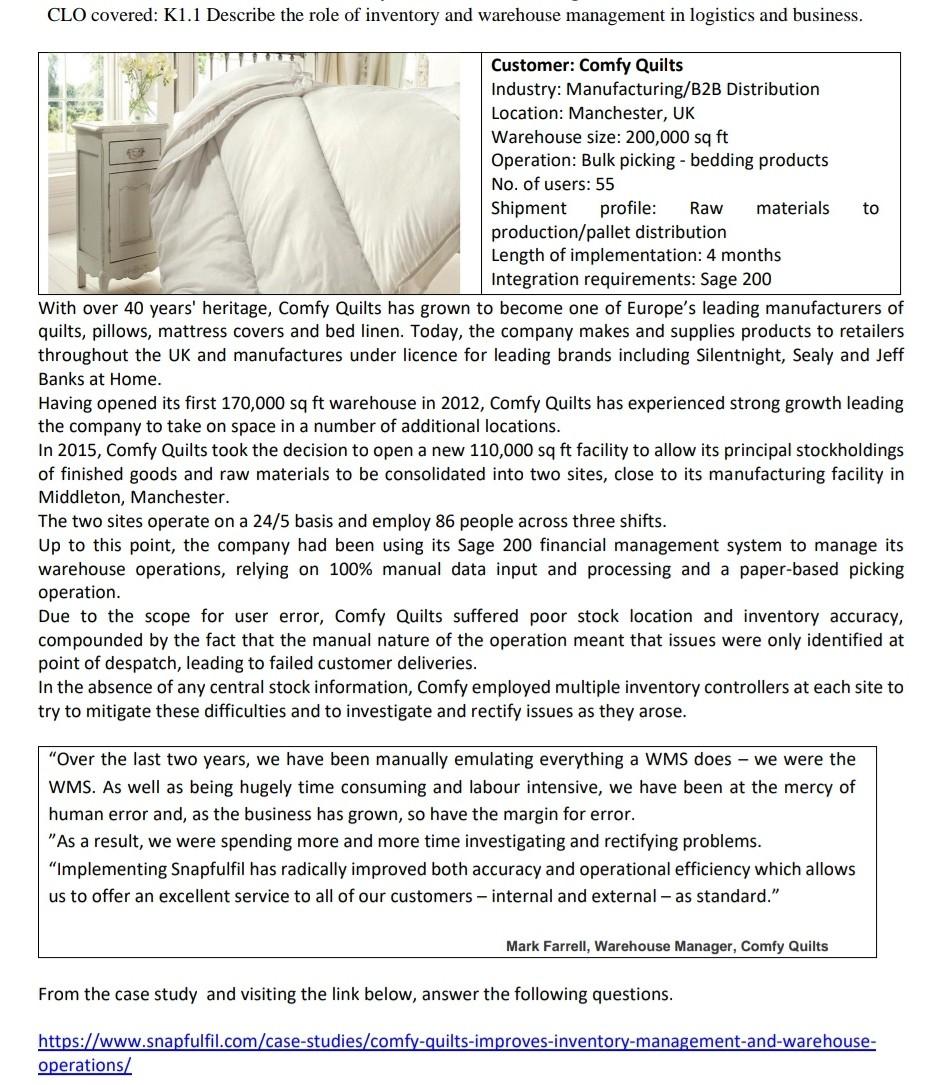

CLO covered: K1.1 Describe the role of inventory and warehouse management in logistics and business. With over 40 years' heritage, Comfy Quilts has grown to become one of Europe's leading manufacturers of quilts, pillows, mattress covers and bed linen. Today, the company makes and supplies products to retailers throughout the UK and manufactures under licence for leading brands including Silentnight, Sealy and Jeff Banks at Home. Having opened its first 170,000sq ft warehouse in 2012, Comfy Quilts has experienced strong growth leading the company to take on space in a number of additional locations. In 2015, Comfy Quilts took the decision to open a new 110,000sqft facility to allow its principal stockholdings of finished goods and raw materials to be consolidated into two sites, close to its manufacturing facility in Middleton, Manchester. The two sites operate on a 24/5 basis and employ 86 people across three shifts. Up to this point, the company had been using its Sage 200 financial management system to manage its warehouse operations, relying on 100% manual data input and processing and a paper-based picking operation. Due to the scope for user error, Comfy Quilts suffered poor stock location and inventory accuracy, compounded by the fact that the manual nature of the operation meant that issues were only identified at point of despatch, leading to failed customer deliveries. In the absence of any central stock information, Comfy employed multiple inventory controllers at each site to try to mitigate these difficulties and to investigate and rectify issues as they arose. "Over the last two years, we have been manually emulating everything a WMS does - we were the WMS. As well as being hugely time consuming and labour intensive, we have been at the mercy of human error and, as the business has grown, so have the margin for error. "As a result, we were spending more and more time investigating and rectifying problems. "Implementing Snapfulfil has radically improved both accuracy and operational efficiency which allows us to offer an excellent service to all of our customers - internal and external - as standard." Mark Farrell, Warehouse Manager, Comfy Quilts From the case study and visiting the link below, answer the following questions. https://www.snapfulfil.com/case-studies/comfy-quilts-improves-inventory-management-and-warehouseoperations/ Ques 1. What are the milestones achieved by Comfy Quilts by implementation of Snapfulfil? Ques 2. List down the benefits of implementation of the Snapfulfil. Ques 3. What are the future strategies of Comfy after implementation of Snapfulfil? CLO covered: K1.1 Describe the role of inventory and warehouse management in logistics and business. With over 40 years' heritage, Comfy Quilts has grown to become one of Europe's leading manufacturers of quilts, pillows, mattress covers and bed linen. Today, the company makes and supplies products to retailers throughout the UK and manufactures under licence for leading brands including Silentnight, Sealy and Jeff Banks at Home. Having opened its first 170,000sq ft warehouse in 2012, Comfy Quilts has experienced strong growth leading the company to take on space in a number of additional locations. In 2015, Comfy Quilts took the decision to open a new 110,000sqft facility to allow its principal stockholdings of finished goods and raw materials to be consolidated into two sites, close to its manufacturing facility in Middleton, Manchester. The two sites operate on a 24/5 basis and employ 86 people across three shifts. Up to this point, the company had been using its Sage 200 financial management system to manage its warehouse operations, relying on 100% manual data input and processing and a paper-based picking operation. Due to the scope for user error, Comfy Quilts suffered poor stock location and inventory accuracy, compounded by the fact that the manual nature of the operation meant that issues were only identified at point of despatch, leading to failed customer deliveries. In the absence of any central stock information, Comfy employed multiple inventory controllers at each site to try to mitigate these difficulties and to investigate and rectify issues as they arose. "Over the last two years, we have been manually emulating everything a WMS does - we were the WMS. As well as being hugely time consuming and labour intensive, we have been at the mercy of human error and, as the business has grown, so have the margin for error. "As a result, we were spending more and more time investigating and rectifying problems. "Implementing Snapfulfil has radically improved both accuracy and operational efficiency which allows us to offer an excellent service to all of our customers - internal and external - as standard." Mark Farrell, Warehouse Manager, Comfy Quilts From the case study and visiting the link below, answer the following questions. https://www.snapfulfil.com/case-studies/comfy-quilts-improves-inventory-management-and-warehouseoperations/ Ques 1. What are the milestones achieved by Comfy Quilts by implementation of Snapfulfil? Ques 2. List down the benefits of implementation of the Snapfulfil. Ques 3. What are the future strategies of Comfy after implementation of Snapfulfil

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started