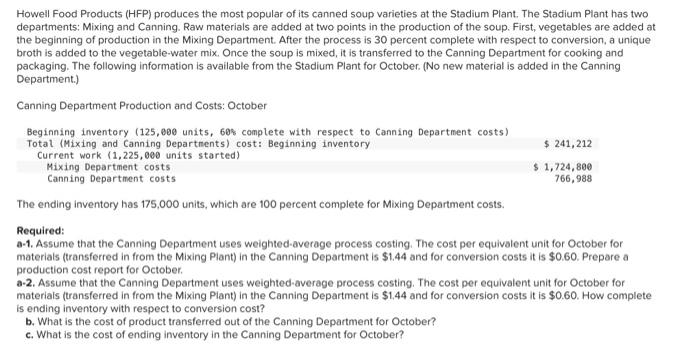

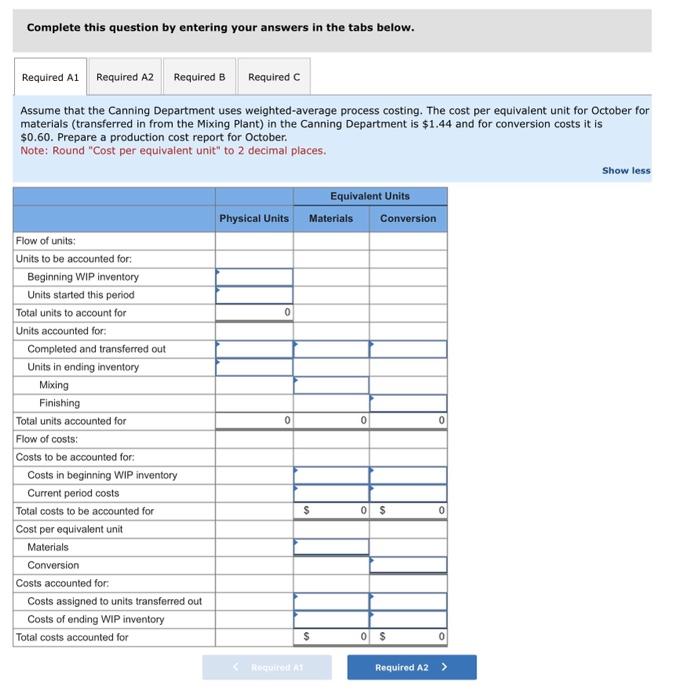

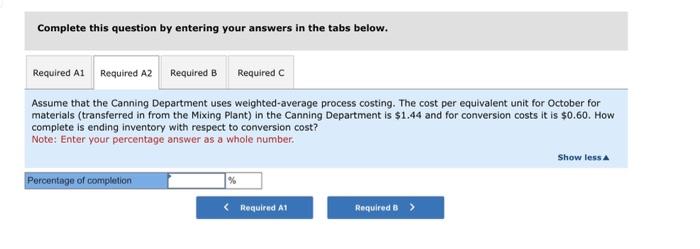

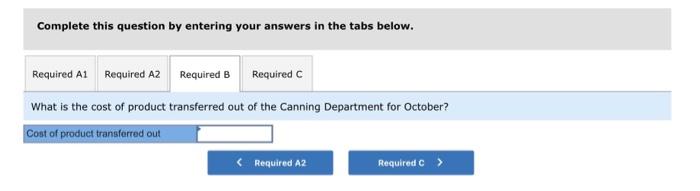

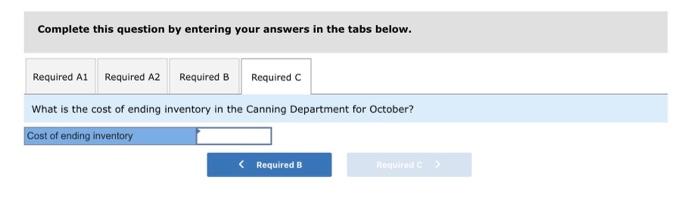

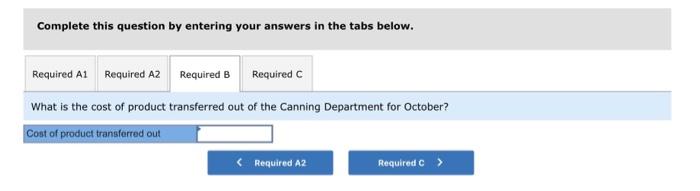

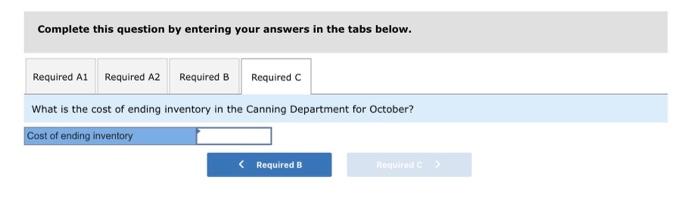

Complete this question by entering your answers in the tabs below. What is the cost of product transferred out of the Canning Department for October? Complete this question by entering your answers in the tabs below. Assume that the Canning Department uses weighted-average process costing. The cost per equivalent unit for October for materials (transferred in from the Mixing Plant) in the Canning Department is $1.44 and for conversion costs it is $0.60. How complete is ending inventory with respect to conversion cost? Note: Enter your percentage answer as a whole number. Complete this question by entering your answers in the tabs below. What is the cost of ending inventory in the Canning Department for October? Complete this question by entering your answers in the tabs below. Assume that the Canning Department uses weighted-average process costing. The cost per equivalent unit for October for materials (transferred in from the Mixing Plant) in the Canning Department is $1.44 and for conversion costs it is $0.60. Prepare a production cost report for October. Note: Round "Cost per equivalent unit" to 2 decimal places. Howell Food Products (HFP) produces the most popular of its canned soup varieties at the Stadium Plant. The Stadium Plant has two departments: Mixing and Canning. Raw materials are added at two points in the production of the soup. First, vegetables are added at the beginning of production in the Mixing Department. After the process is 30 percent complete with respect to conversion, a unique broth is added to the vegetable-water mix. Once the soup is mixed, it is transferred to the Canning Department for cooking and packaging. The following information is available from the Stadium Plant for October. (No new material is added in the Canning Department.) Canning Department Production and Costs: October Beginning inventory (125,000 units, 608 complete with respect to Canning Department costs) Total (Mixing and Canning Departments) cost: Beginning inventory $241,212 Current work (1,225,000 units started ) Mixing Department costs \$ 1,724,800 Canning Department costs 766,988 The ending inventory has 175,000 units, which are 100 percent complete for Mixing Department costs. Required: a-1. Assume that the Canning Department uses weighted-average process costing. The cost per equivalent unit for October for materials (transferred in from the Mixing Plant) in the Canning Department is $1.44 and for conversion costs it is $0.60. Prepare a production cost report for October. a-2. Assume that the Canning Department uses weighted-average process costing. The cost per equivalent unit for October for materials (transferred in from the Mixing Plant) in the Canning Department is $1.44 and for conversion costs it is $0.60. How complete is ending inventory with respect to conversion cost? b. What is the cost of product transferred out of the Canning Department for October? c. What is the cost of ending inventory in the Canning Department for October? Complete this question by entering your answers in the tabs below. What is the cost of product transferred out of the Canning Department for October? Complete this question by entering your answers in the tabs below. Assume that the Canning Department uses weighted-average process costing. The cost per equivalent unit for October for materials (transferred in from the Mixing Plant) in the Canning Department is $1.44 and for conversion costs it is $0.60. How complete is ending inventory with respect to conversion cost? Note: Enter your percentage answer as a whole number. Complete this question by entering your answers in the tabs below. What is the cost of ending inventory in the Canning Department for October? Complete this question by entering your answers in the tabs below. Assume that the Canning Department uses weighted-average process costing. The cost per equivalent unit for October for materials (transferred in from the Mixing Plant) in the Canning Department is $1.44 and for conversion costs it is $0.60. Prepare a production cost report for October. Note: Round "Cost per equivalent unit" to 2 decimal places. Howell Food Products (HFP) produces the most popular of its canned soup varieties at the Stadium Plant. The Stadium Plant has two departments: Mixing and Canning. Raw materials are added at two points in the production of the soup. First, vegetables are added at the beginning of production in the Mixing Department. After the process is 30 percent complete with respect to conversion, a unique broth is added to the vegetable-water mix. Once the soup is mixed, it is transferred to the Canning Department for cooking and packaging. The following information is available from the Stadium Plant for October. (No new material is added in the Canning Department.) Canning Department Production and Costs: October Beginning inventory (125,000 units, 608 complete with respect to Canning Department costs) Total (Mixing and Canning Departments) cost: Beginning inventory $241,212 Current work (1,225,000 units started ) Mixing Department costs \$ 1,724,800 Canning Department costs 766,988 The ending inventory has 175,000 units, which are 100 percent complete for Mixing Department costs. Required: a-1. Assume that the Canning Department uses weighted-average process costing. The cost per equivalent unit for October for materials (transferred in from the Mixing Plant) in the Canning Department is $1.44 and for conversion costs it is $0.60. Prepare a production cost report for October. a-2. Assume that the Canning Department uses weighted-average process costing. The cost per equivalent unit for October for materials (transferred in from the Mixing Plant) in the Canning Department is $1.44 and for conversion costs it is $0.60. How complete is ending inventory with respect to conversion cost? b. What is the cost of product transferred out of the Canning Department for October? c. What is the cost of ending inventory in the Canning Department for October