Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Consider a forward area where cases (cartons) are picked from pallets. Full-pallet picks are all picked from reserve storage so they are not considered

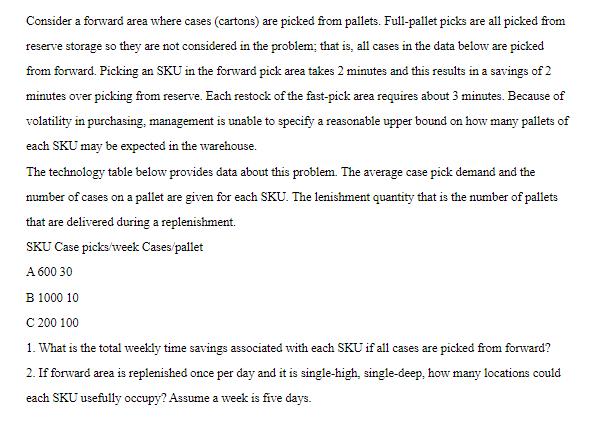

Consider a forward area where cases (cartons) are picked from pallets. Full-pallet picks are all picked from reserve storage so they are not considered in the problem; that is, all cases in the data below are picked from forward. Picking an SKU in the forward pick area takes 2 minutes and this results in a savings of 2 minutes over picking from reserve. Each restock of the fast-pick area requires about 3 minutes. Because of volatility in purchasing, management is unable to specify a reasonable upper bound on how many pallets of each SKU may be expected in the warehouse. The technology table below provides data about this problem. The average case pick demand and the number of cases on a pallet are given for each SKU. The lenishment quantity that is the number of pallets that are delivered during a replenishment. SKU Case picks/week Cases/pallet A 600 30 B 1000 10 C 200 100 1. What is the total weekly time savings associated with each SKU if all cases are picked from forward? 2. If forward area is replenished once per day and it is single-high, single-deep, how many locations could each SKU usefully occupy? Assume a week is five days.

Step by Step Solution

★★★★★

3.33 Rating (150 Votes )

There are 3 Steps involved in it

Step: 1

SOLUTION To calculate the total weekly time savings associated with each SKU if all cases are picked from the forward pick area we need to consider the average case pick demand and the number of cases ...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started