Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Consider a transportation problem with three leather supply centers located at St. Lowis, Houston er, and four markets for leather bags located at large metropolitan

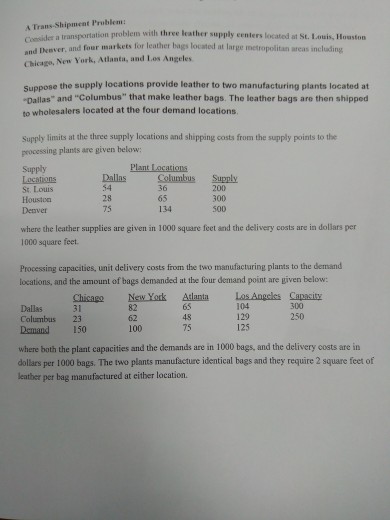

Consider a transportation problem with three leather supply centers located at St. Lowis, Houston er, and four markets for leather bags located at large metropolitan areas inclading Chicago, New York, Atlanta, and Los Angeles Suppose the supply locations provide leather to two manufacturing plants located at Dallas" and "Columbus" that make leather bags. The leather bags are then shipped to wholesalers located at the four demand locations Supply limits at the three supply locations and shipping costs from the supply points to the processing plants are given below: Supply DallasColumbus Supply St. Louis Houston Denver 28 75 36 65 134 200 300 500 where the leather supplies are given in 1000 square feet and the delivery costs are in dollars per 1000 square feet. Processing capacities, unit delivery costs from the two manufacturing plants to the demand locations, and the amount of bags demanded at the four demand point are given below: ChicagoNew York Adanta Ls Angcles Capasity 31 82 62 100 48 75 104 129 125 300 250 Columbus 23 Demand150 where both the plant capacities and the demands are in 1000 bags, and the delivery costs are in dollars per 1000 bags. The two plants manufacture identical bags and they require 2 square feet of eather per bag manufactured at either location. Consider a transportation problem with three leather supply centers located at St. Lowis, Houston er, and four markets for leather bags located at large metropolitan areas inclading Chicago, New York, Atlanta, and Los Angeles Suppose the supply locations provide leather to two manufacturing plants located at Dallas" and "Columbus" that make leather bags. The leather bags are then shipped to wholesalers located at the four demand locations Supply limits at the three supply locations and shipping costs from the supply points to the processing plants are given below: Supply DallasColumbus Supply St. Louis Houston Denver 28 75 36 65 134 200 300 500 where the leather supplies are given in 1000 square feet and the delivery costs are in dollars per 1000 square feet. Processing capacities, unit delivery costs from the two manufacturing plants to the demand locations, and the amount of bags demanded at the four demand point are given below: ChicagoNew York Adanta Ls Angcles Capasity 31 82 62 100 48 75 104 129 125 300 250 Columbus 23 Demand150 where both the plant capacities and the demands are in 1000 bags, and the delivery costs are in dollars per 1000 bags. The two plants manufacture identical bags and they require 2 square feet of eather per bag manufactured at either location

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started