Answered step by step

Verified Expert Solution

Question

1 Approved Answer

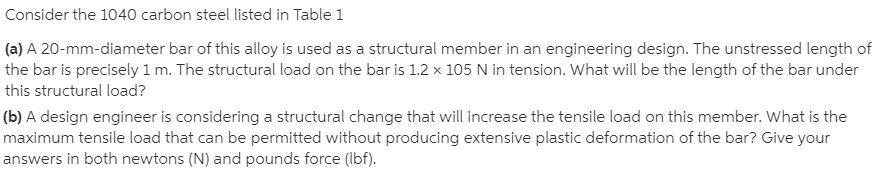

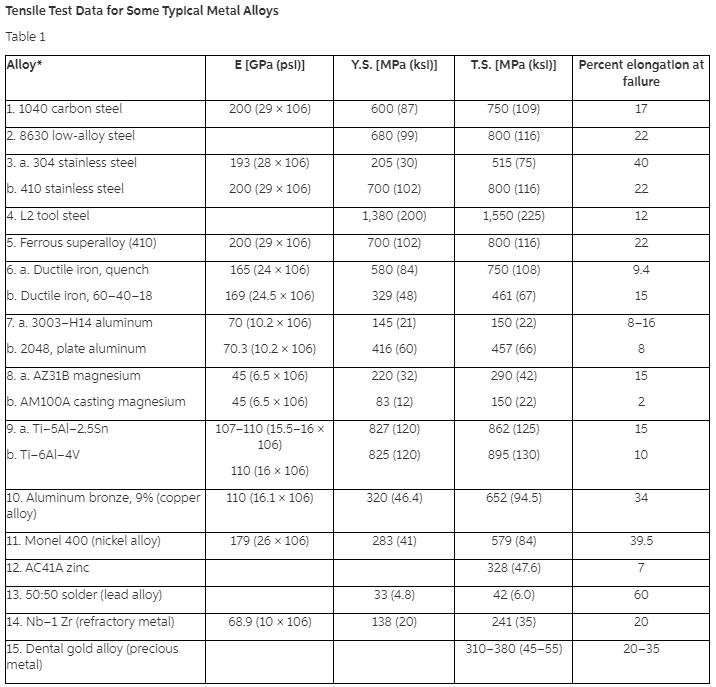

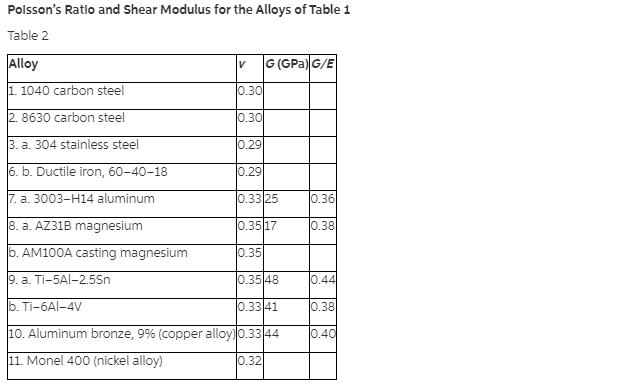

Consider the 1040 carbon steel listed in Table 1 (a) A 20-mm-diameter bar of this alloy is used as a structural member in an

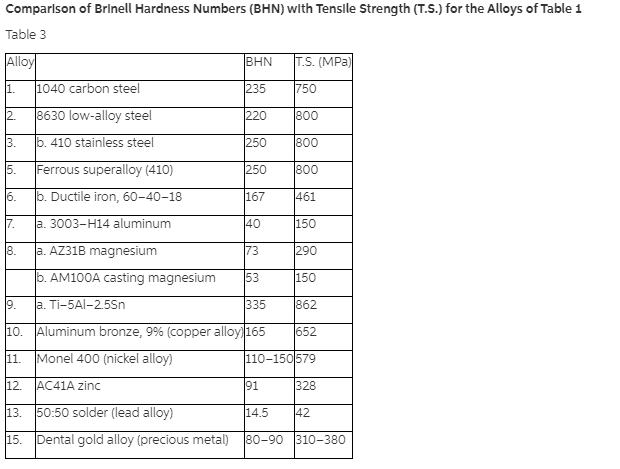

Consider the 1040 carbon steel listed in Table 1 (a) A 20-mm-diameter bar of this alloy is used as a structural member in an engineering design. The unstressed length of the bar is precisely 1 m. The structural load on the bar is 1.2 x 105 N in tension. What will be the length of the bar under this structural load? (b) A design engineer is considering a structural change that will increase the tensile load on this member. What is the maximum tensile load that can be permitted without producing extensive plastic deformation of the bar? Give your answers in both newtons (N) and pounds force (lbf). Tenslle Test Data for Some Typlcal Metal Alloys Table 1 Alloy* Y.S. [MPa (ksl)] T.S. [MPa (ksl)) Percent elongatlon at E [GPa (psl)] fallure 1. 1040 carbon steel 600 (87) 750 (109) 200 (29 x 106) 17 680 (99) 800 (116) 2. 8630 low-alloy steel 22 205 (30) 515 (75) 3. a. 304 stainless steel 193 (28 x 106) 40 b. 410 stainless steel 200 (29 x 106) 700 (102) 800 (116) 22 4. L2 tool steel 1,380 (200) 1,550 (225) 12 5. Ferrous superalloy (410) 700 (102) 800 (116) 200 (29 x 106) 22 6. a. Ductile iron, quench 580 (84) 750 (108) 165 (24 x 106) 9.4 b. Ductile iron, 60-40-18 461 (67) 169 (24.5 x 106) 329 (48) 15 7. a. 3003-H14 aluminum 145 (21) 70 (10.2 x 106) 150 (22) 8-16 b. 2048, plate aluminum 416 (60) 70.3 (10.2 x 106) 457 (66) 290 (42) 8. a. AZ31B magnesium 220 (32) 45 (6.5 x 106) 15 b. AM100A casting magnesium 83 (12) 150 (22) 45 (6.5 x 106) 2. 9. a. Ti-5Al-2.55n 827 (120) 862 (125) 107-110 (15.5-16 x 106) 15 825 (120) b. Ti-6Al-4V 895 (130) 10 110 (16 x 106) 320 (46.4) 10. Aluminum bronze, 9% (copper 110 (16.1 x 106) 652 (94.5) 34 alloy) 11. Monel 400 (nickel alloy) 579 (84) 179 (26 x 106) 283 (41) 39.5 328 (47.6) 12. AC41A zinc 13. 50:50 solder (lead alloy) 33 (4.8) 42 (6.0) 60 14. Nb-1 Zr (refractory metal) 138 (20) 241 (35) 68.9 (10 x 106) 20 15. Dental gold alloy (precious metal) 310-380 (45-55) 20-35 Polsson's Ratlo and Shear Modulus for the Alloys of Table 1 Table 2 Alloy G (GPa) G/E 1. 1040 carbon steel 0.30 2. 8630 carbon steel 0.30 3. a. 304 stainless steel 0.29 6. b. Ductile iron, 60-40-18 0.29 0.33 25 0.36 7. a. 3003-H14 aluminum 8. a. AZ31B magnesium 0.35 17 0.38 b. AM100A casting magnesium 0.35 9. a. Ti-5AI-2.5Sn 0.44 0.35 48 b. Ti-6AI-4V 0.33 41 0.38 10. Aluminum bronze, 9% (copper alloy) 0.33 44 0.40 11. Monel 400 (nickel alloy) 0.32 Comparlson of Brinell Hardness Numbers (BHN) with Tenslle Strength (T.S.) for the Alloys of Table 1 Table 3 Alloy T.S. (MPa) BHN 1040 carbon steel 235 1. 750 8630 low-alloy steel 220 12. 800 b. 410 stainless steel 3. 250 800 Ferrous superalloy (410) 250 5. 800 b. Ductile iron, 60-40-18 167 6. 461 7. a. 3003-H14 aluminum 40 150 la. AZ31B magnesium 290 8. 73 b. AM100A casting magnesium 53 150 335 9. a. Ti-5Al-2.5Sn 862 10. Aluminum bronze, 9% (copper alloy 165 652 Monel 400 (nickel alloy) 110-150579 11. AC41A zinc 91 12. 328 13. 50:50 solder (lead alloy) 14.5 42 Dental gold alloy (precious metal) 80-90 310-380 15.

Step by Step Solution

★★★★★

3.47 Rating (157 Votes )

There are 3 Steps involved in it

Step: 1

Above images ...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Document Format ( 2 attachments)

606ad568668e0_49886.pdf

180 KBs PDF File

606ad568668e0_49886.docx

120 KBs Word File

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started