Answered step by step

Verified Expert Solution

Question

1 Approved Answer

CONTACT PROCESS - SULPHURIC ACID PRODUCTION Background The largest producers and users of sulfuric acid are the fertilizer manufacturers and the mining industry where sulfuric

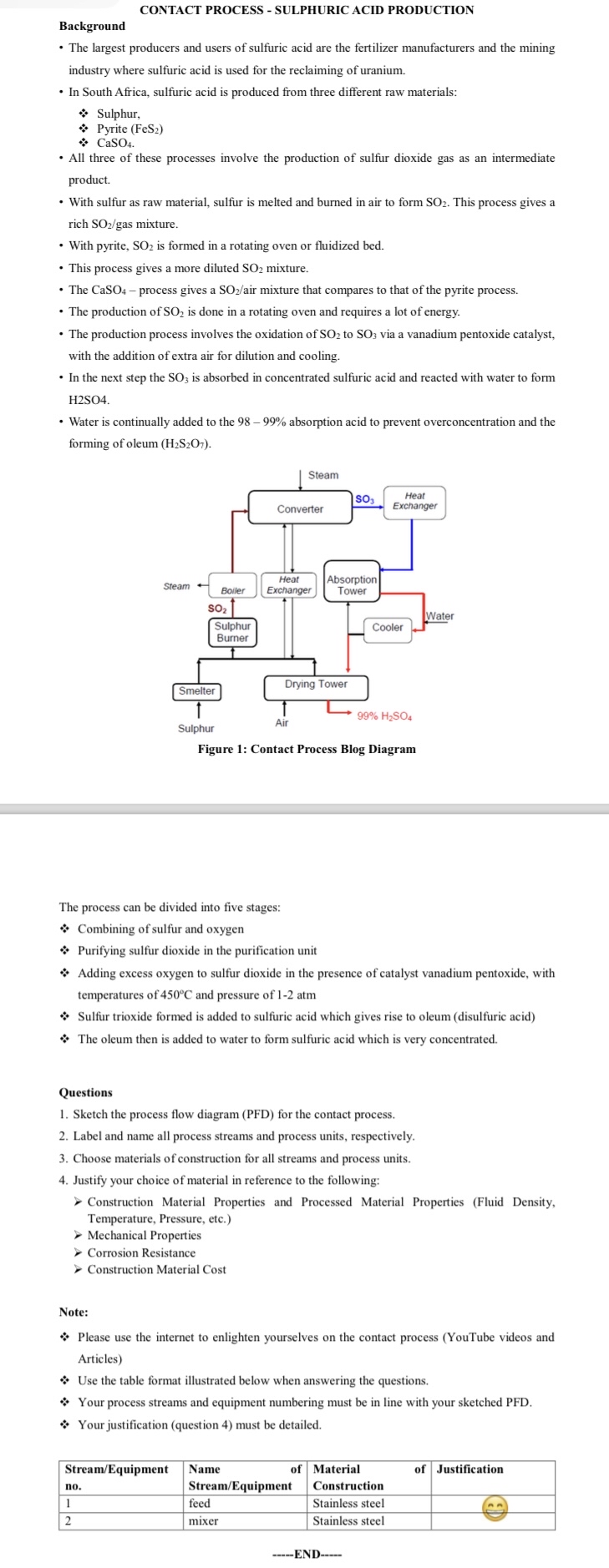

CONTACT PROCESS SULPHURIC ACID PRODUCTION

Background

The largest producers and users of sulfuric acid are the fertilizer manufacturers and the mining industry where sulfuric acid is used for the reclaiming of uranium.

In South Africa, sulfuric acid is produced from three different raw materials:

S Sulphur,

Pyrite

All three of these processes involve the production of sulfur dioxide gas as an intermediate product.

With sulfur as raw material, sulfur is melted and burned in air to form This process gives a rich gas mixture.

With pyrite, is formed in a rotating oven or fluidized bed.

This process gives a more diluted mixture.

The process gives a air mixture that compares to that of the pyrite process.

The production of is done in a rotating oven and requires a lot of energy.

The production process involves the oxidation of to via a vanadium pentoxide catalyst, with the addition of extra air for dilution and cooling.

In the next step the is absorbed in concentrated sulfuric acid and reacted with water to form

Water is continually added to the absorption acid to prevent overconcentration and the forming of oleum

The process can be divided into five stages:

Combining of sulfur and oxygen

& Purifying sulfur dioxide in the purification unit

& Adding excess oxygen to sulfur dioxide in the presence of catalyst vanadium pentoxide, with temperatures of and pressure of atm

Sulfur trioxide formed is added to sulfuric acid which gives rise to oleum disulfuric acid

The oleum then is added to water to form sulfuric acid which is very concentrated.

Questions

Sketch the process flow diagram PFD for the contact process.

Label and name all process streams and process units, respectively.

Choose materials of construction for all streams and process units.

Justify your choice of material in reference to the following:Note:& Please use the internet to enlighten yourselves on the contact process YouTube videos and Articles

Use the table format illustrated below when answering the questions.

& Your process streams and equipment numbering must be in line with your sketched PFD

& Your justification question must be detailed.

tabletableStreamEquipmentnotableName ofStreamEquipmenttableMaterial ofConstructionJustificationfeed,Stainless steel,mixer,Stainless steel,

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started