Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Controlled Move Show times in TMUs and seconds. (1) An associate grasps an oven door within reach and pulls itopen 18 inches with the left

Controlled Move Show times in TMUs and seconds.

(1) An associate grasps an oven door within reach and pulls itopen 18 inches with the left hand (he does not relinquish controlof the door). With a pan in the right hand, he carefully positionsthe pan in the oven and then slides it 6 inches with high control.He removes his hand for safety reasons and then closes thedoor.

(2) Gain control of a lever, hidden from view, within reach andpull it 18 inches down and then 10 inches to the side.

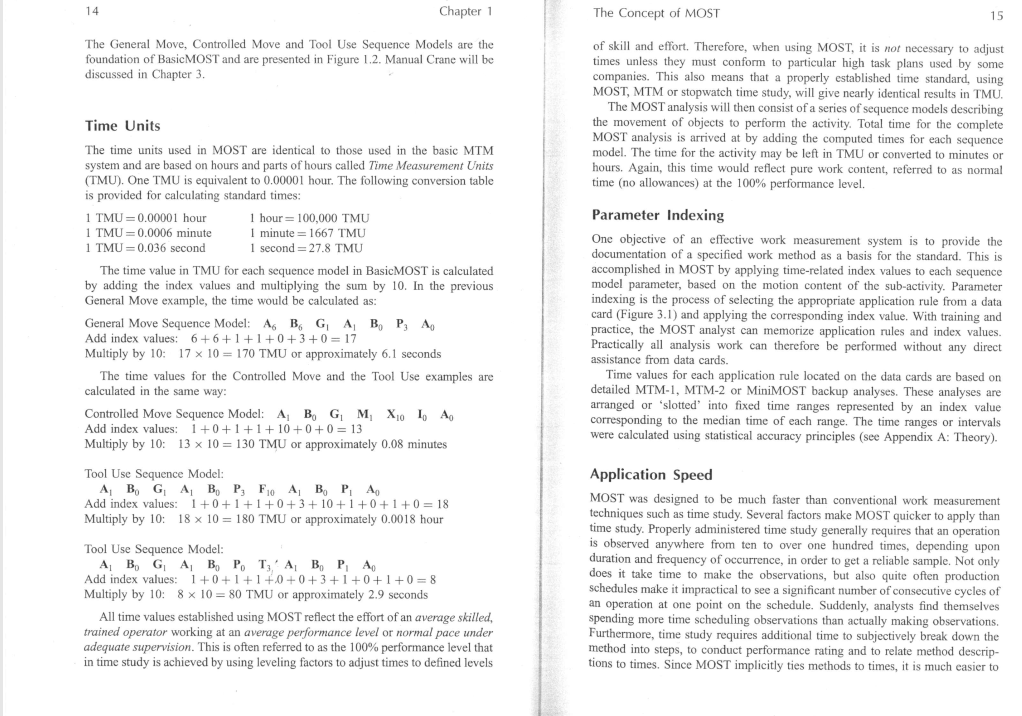

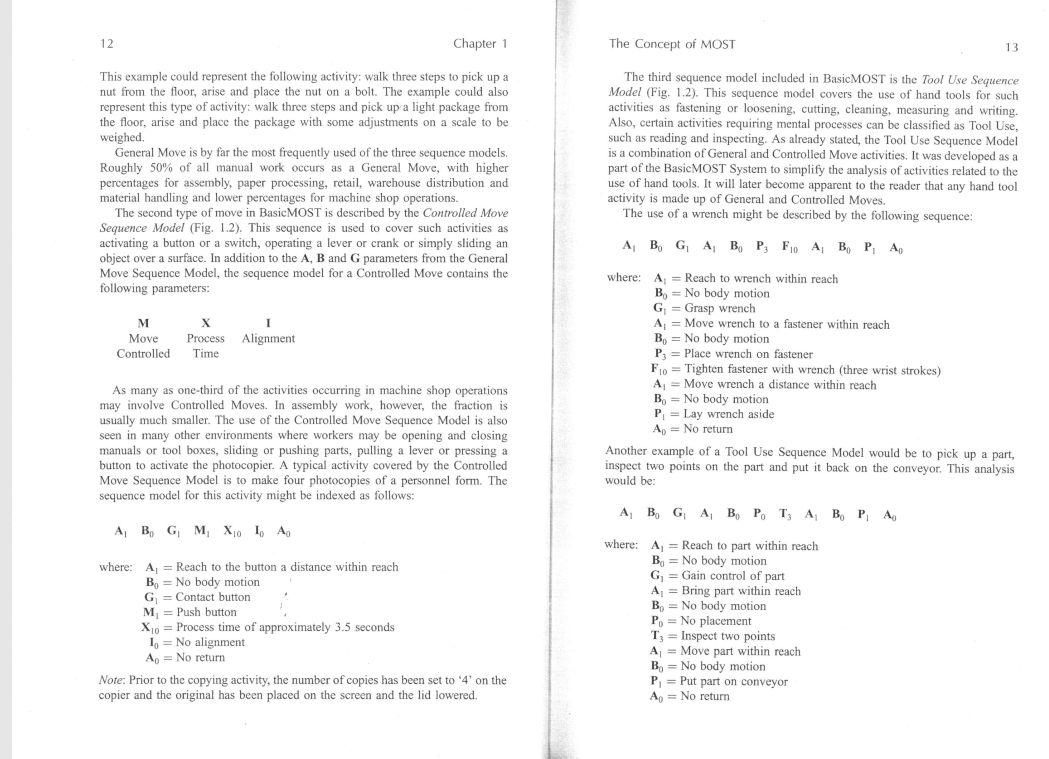

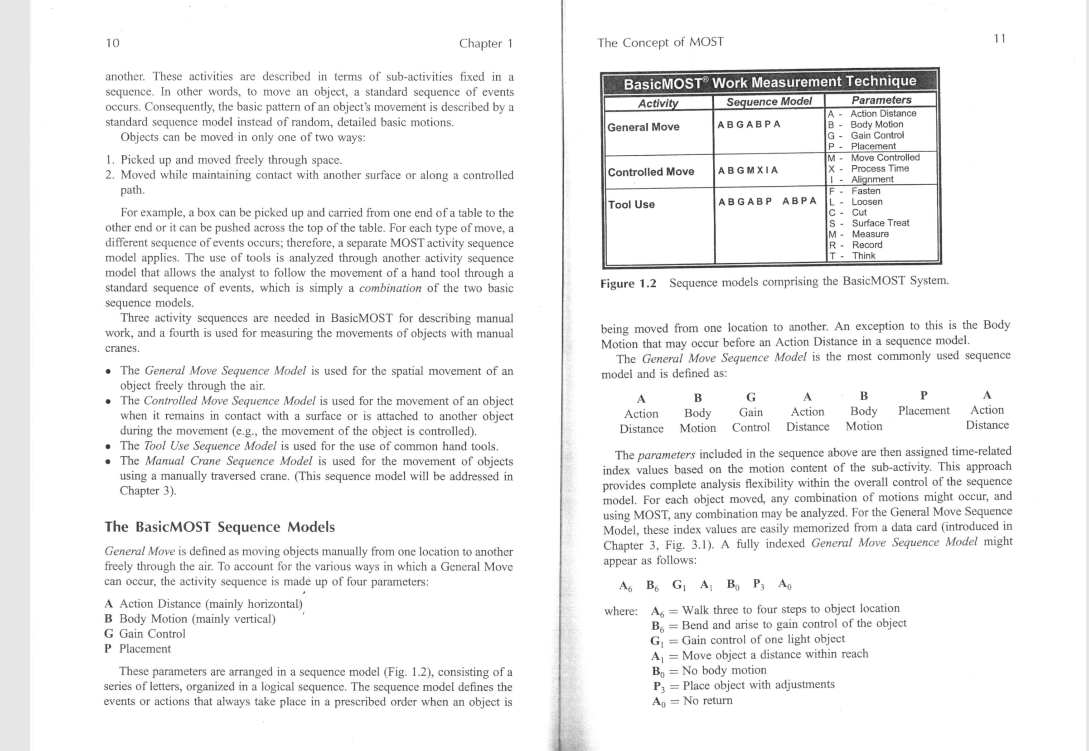

14 Chapter 1 The General Move, Controlled Move and Tool Use Sequence Models are the foundation of BasicMOST and are presented in Figure 1.2. Manual Crane will be discussed in Chapter 3. Time Units The time units used in MOST are identical to those used in the basic MTM system and are based on hours and parts of hours called Time Measurement Units (TMU). One TMU is equivalent to 0.00001 hour. The following conversion table is provided for calculating standard times: 1 TMU=0.00001 hour 1 TMU=0.0006 minute 1 TMU 0.036 second 1 hour 100,000 TMU 1 minute = 1667 TMU 1 second = 27.8 TMU The time value in TMU for each sequence model in BasicMOST is calculated by adding the index values and multiplying the sum by 10. In the previous General Move example, the time would be calculated as: General Move Sequence Model: A6 B G A Bo P3 Ao Add index values: 6+6+1+1+0+3+0=17 Multiply by 10: 17 x 10 = 170 TMU or approximately 6.1 seconds The time values for the Controlled Move and the Tool Use examples are calculated in the same way: Controlled Move Sequence Model: A Bo G M X0 Io Ao Add index values: 1+0+1+1+10+0+0=13 Multiply by 10: 13 x 10 = 130 TMU or approximately 0.08 minutes Tool Use Sequence Model: A Bo G A Bo P3 F10 A Bo P Ao Add index values: 1+0+1+1+0+3+10+1+0+1+0=18 Multiply by 10: 18 x 10 = 180 TMU or approximately 0.0018 hour Tool Use Sequence Model: A Bo G A Bo Po T3, A Bo P A Add index values: 1+0+1+1+0+0+3+1+0+1+0=8 Multiply by 10: 8 x 1080 TMU or approximately 2.9 seconds All time values established using MOST reflect the effort of an average skilled, trained operator working at an average performance level or normal pace under adequate supervision. This is often referred to as the 100% performance level that in time study is achieved by using leveling factors to adjust times to defined levels The Concept of MOST of skill and effort. Therefore, when using MOST, it is not necessary to adjust times unless they must conform to particular high task plans used by some companies. This also means that a properly established time standard, using MOST, MTM or stopwatch time study, will give nearly identical results in TMU. The MOST analysis will then consist of a series of sequence models describing the movement of objects to perform the activity. Total time for the complete MOST analysis is arrived at by adding the computed times for each sequence model. The time for the activity may be left in TMU or converted to minutes or hours. Again, this time would reflect pure work content, referred to as normal time (no allowances) at the 100% performance level. 15 Parameter Indexing One objective of an effective work measurement system is to provide the documentation of a specified work method as a basis for the standard. This is accomplished in MOST by applying time-related index values to each sequence model parameter, based on the motion content of the sub-activity. Parameter indexing is the process of selecting the appropriate application rule from a data card (Figure 3.1) and applying the corresponding index value. With training and practice, the MOST analyst can memorize application rules and index values. Practically all analysis work can therefore be performed without any direct assistance from data cards. Time values for each application rule located on the data cards are based on detailed MTM-1, MTM-2 or MiniMOST backup analyses. These analyses are arranged or 'slotted' into fixed time ranges represented by an index value corresponding to the median time of each range. The time ranges or intervals were calculated using statistical accuracy principles (see Appendix A: Theory). Application Speed MOST was designed to be much faster than conventional work measurement techniques such as time study. Several factors make MOST quicker to apply than time study. Properly administered time study generally requires that an operation is observed anywhere from ten to over one hundred times, depending upon duration and frequency of occurrence, in order to get a reliable sample. Not only does it take time to make the observations, but also quite often production schedules make it impractical to see a significant number of consecutive cycles of an operation one point on the schedule. Suddenly, analysts find themselves. spending more time scheduling observations than actually making observations. Furthermore, time study requires additional time to subjectively break down the method into steps, to conduct performance rating and to relate method descrip- tions to times. Since MOST implicitly ties methods to times, it is much easier to

Step by Step Solution

There are 3 Steps involved in it

Step: 1

To calculate the times in Time Measurement Units TMUs and seconds for the two Controlled Move scenarios provided in the question we will use the Contr...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started