Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Could you provide the answers for the case study below. For questions 1 and 2 please show step by step working out. CASE CASE 2.1

Could you provide the answers for the case study below. For questions 1 and 2 please show step by step working out.

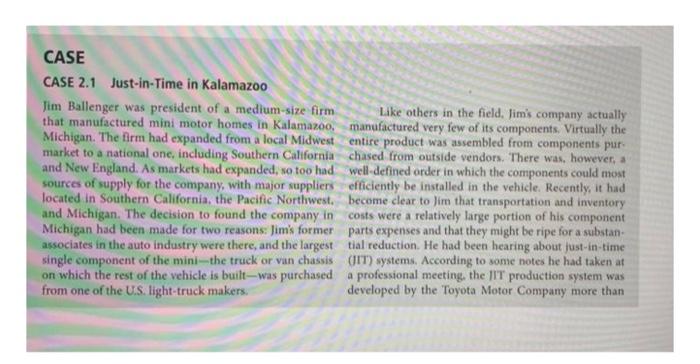

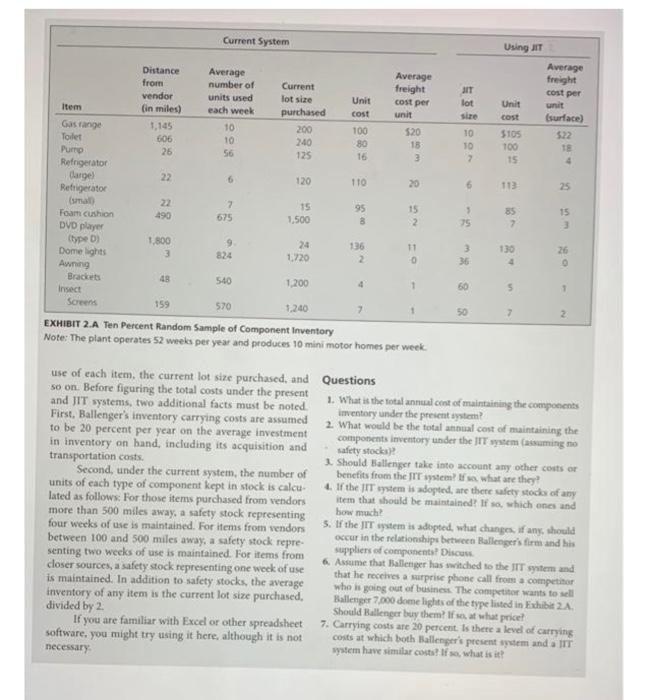

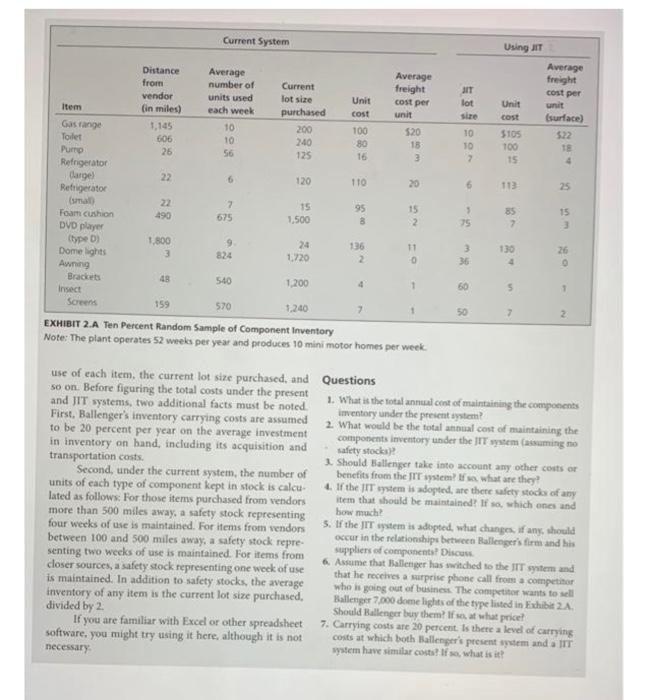

CASE CASE 2.1 Just-in-Time in Kalamazoo Jim Ballenger was president of a medium-size firm Like others in the field. limis company actually that manufactured mini motor homes in Kalamazoo, manufactured very few of its components. Virtually the Michigan. The firm had expanded from a local Midwest entire product was assembled from components purmarket to a national one, including Southern California chased from outside vendors. There was, however, a and New England. As markets had expanded, so too had well-defined order in which the components could most sources of supply for the company, with major suppliers efficiently be installed in the vehicle. Recently, it had located in Southern California, the Pacific Northwest, become clear to Jim that transportation and inventory and Michigan. The decision to found the company in costs were a relatively large portion of his component Michigan had been made for two reasons: Jims former parts expenses and that they might be ripe for a substan. associates in the auto industry were there, and the largest tial reduction. He had been hearing about just-in-time single component of the mini-the truck or van chassis. (IIT) systems. According to some notes he had taken at on which the rest of the vehicle is built - was purchased a professional meeting, the IIT production system was from one of the U.S. light-truck makers. So years ago ft involves an apposch to inventory that, in (generally tacit) asumption that there would be some turn, forces a complementary approach to prodoctios, defective coeponents purchased and that there would quality control, supplier relations, and distrilsator rela. Whely he sotocthing wrong wiah his prodact when if tionships. The major tenets of 11 can be mamasariad first came ofl the awembly line. For this reason, the 2. Minimum repieniahment quanticy is maintained installation. To the entert that only a fere of a particular 3. Minimam inventory of semifiniahed goods should prodaction schickiale wueld be that much gealef it might The finiohed prodact thould be delivered on a very. that be was uing a publs warchouse near his plant that short lead time. To the US. inventory planner, vice previsent of monch for the borrowed fundi ased to buy it, as well as logiatics, and production planner, as operation ran en eperses relating to the ase of the warchouse itself. In the preceding principles raived a number of distarking addition. his firm was now producing so mary differprospects. Jim Ballenger was very aware of the costs est modds (ooe with a bath, ene with a shower only) that might arise if a IIT productioe system were to be and wing so many different appliances (various types established. From the materials manugement stand- of radia, three varieties of refrigrrater, etc) that the point, the idea of deliberately phanning many small costs of a solety stock for each coeponent were going shiptients rather than a few large ones apeated to werery dry enaure bigher freight bills, epecially from moce dis- As an aid to making his decision on whether tant sappliers, for which freight rates woold make the to try a 117 orientation at his plant. limis eccos most difference. With regand to coepectition among supplien, fim summarited the anticiputed impacts of a IIT system often had the opportunify in the volatile mini-mosie. (see fahibit 2.A). The figures are bused an random bome market, to buy out parts and coeppoesest vapiles samples of invmtory hems. The mapor camponernt of ticular parta be terpporarily incteased or that parchuen tions, it woold always be available on decmand. ft frum existisg vendors be temporarily curtailnd Furaps wold be delivered through the local dealer. If the the greutest qoedion rained by fiT, howeve, had to do dealer dis not bave ane in stock, ene could eauly be with the probshility of much mure erratic jeoduction a elenined from another area dealerihip. L.m.res aim ven rercent Kanaom sample of Component inventory Note: The plant operates 52 weeks per year and produces 10 mini motor homes per week

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started