Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Crossland would like to move to just-in-time (JIT) system of purchasing its goods from Essel and as a result Essel is contemplating major changes

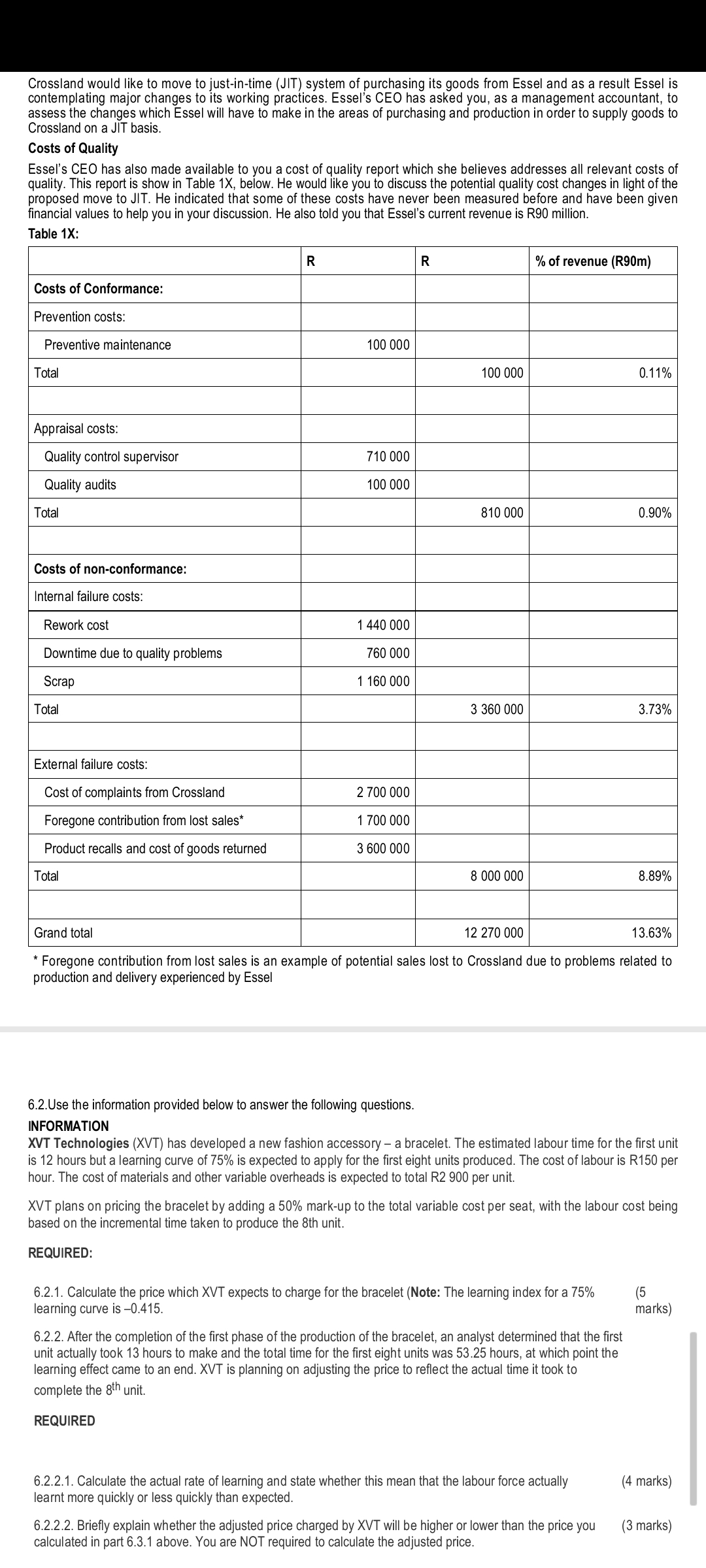

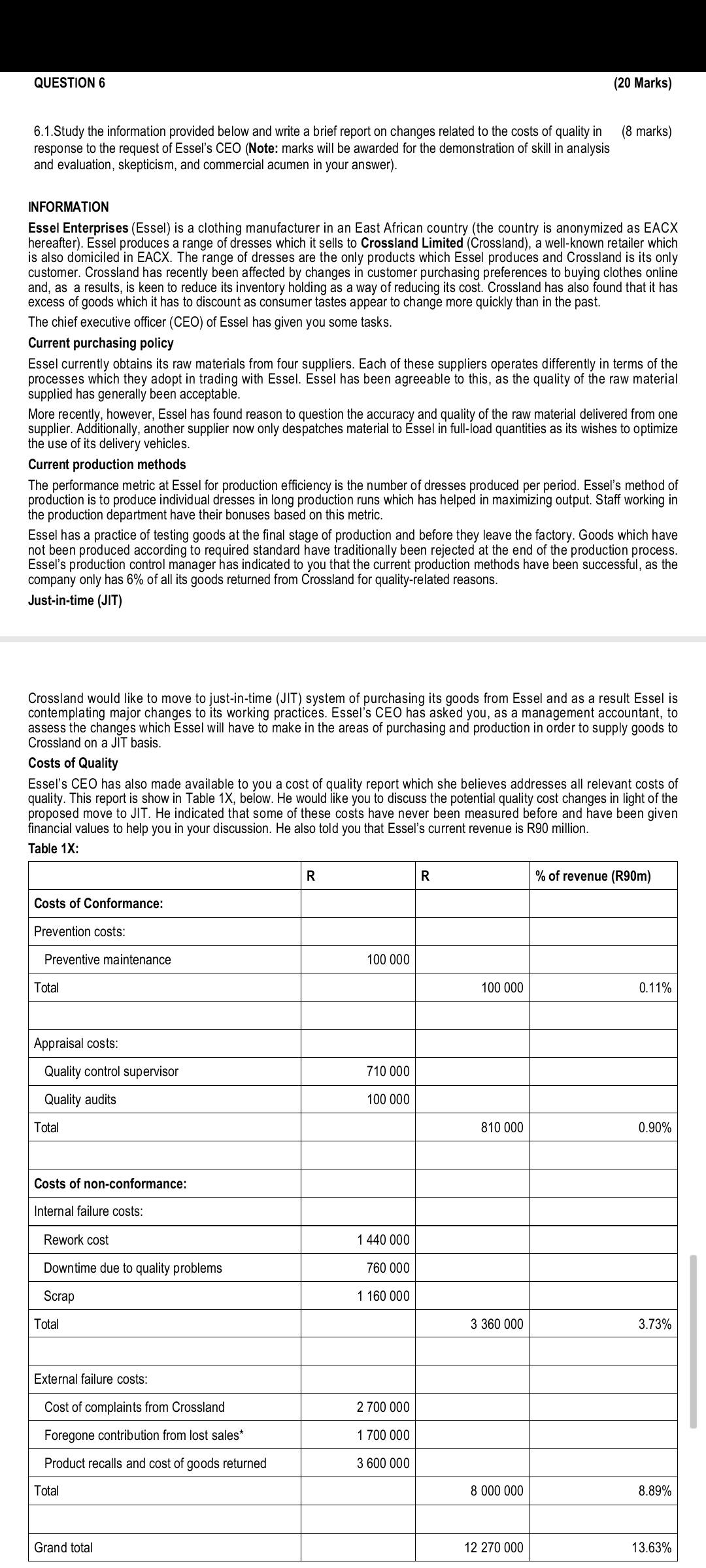

Crossland would like to move to just-in-time (JIT) system of purchasing its goods from Essel and as a result Essel is contemplating major changes to its working practices. Essel's CEO has asked you, as a management accountant, to assess the changes which Essel will have to make in the areas of purchasing and production in order to supply goods to Crossland on a JIT basis. Costs of Quality Essel's CEO has also made available to you a cost of quality report which she believes addresses all relevant costs of quality. This report is show in Table 1X, below. He would like you to discuss the potential quality cost changes in light of the proposed move to JIT. He indicated that some of these costs have never been measured before and have been given financial values to help you in your discussion. He also told you that Essel's current revenue is R90 million. Table 1X: Costs of Conformance: Prevention costs: Preventive maintenance Total Appraisal costs: Quality control supervisor Quality audits Total Costs of non-conformance: Internal failure costs: Rework cost Downtime due to quality problems Scrap Total External failure costs: Cost of complaints from Crossland Foregone contribution from lost sales* Product recalls and cost of goods returned Total R 100 000 710 000 100 000 1 440 000 760 000 1 160 000 2 700 000 1 700 000 3 600 000 R 6.2.Use the information provided below to answer the following questions. INFORMATION 100 000 810 000 3 360 000 8 000 000 % of revenue (R90m) Grand total 12 270 000 Foregone contribution from lost sales is an example of potential sales lost to Crossland due to problems related to production and delivery experienced by Essel 6.2.1. Calculate the price which XVT expects to charge for the bracelet (Note: The learning index for a 75% learning curve is -0.415. 0.11% 6.2.2. After the completion of the first phase of the production of the bracelet, an analyst determined that the first unit actually took 13 hours to make and the total time for the first eight units was 53.25 hours, at which point the learning effect came to an end. XVT is planning on adjusting the price to reflect the actual time it took to complete the 8th unit. REQUIRED 0.90% 6.2.2.1. Calculate the actual rate of learning and state whether this mean that the labour force actually learnt more quickly or less quickly than expected. 3.73% XVT Technologies (XVT) has developed a new fashion accessory - a bracelet. The estimated labour time for the first unit is 12 hours but a learning curve of 75% is expected to apply for the first eight units produced. The cost of labour is R150 per hour. The cost of materials and other variable overheads is expected to total R2 900 per unit. 6.2.2.2. Briefly explain whether the adjusted price charged by XVT will be higher or lower than the price you calculated in part 6.3.1 above. You are NOT required to calculate the adjusted price. 8.89% XVT plans on pricing the bracelet by adding a 50% mark-up to the total variable cost per seat, with the labour cost being based on the incremental time taken to produce the 8th unit. REQUIRED: 13.63% (5 marks) (4 marks) (3 marks) QUESTION 6 6.1.Study the information provided below and write a brief report on changes related to the costs of quality in response to the request of Essel's CEO (Note: marks will be awarded for the demonstration of skill in analysis and evaluation, skepticism, and commercial acumen in your answer). INFORMATION The chief executive officer (CEO) of Essel has given you some tasks. Current purchasing policy Essel Enterprises (Essel) is a clothing manufacturer in an East African country (the country is anonymized as EACX hereafter). Essel produces a range of dresses which it sells to Crossland Limited (Crossland), a well-known retailer which is also domiciled in EACX. The range of dresses are the only products which Essel produces and Crossland is its only customer. Crossland has recently been affected by changes in customer purchasing preferences to buying clothes online and, as a results, is keen to reduce its inventory holding as a way of reducing its cost. Crossland has also found that it has excess of goods which it has discount as consumer tastes appear to change more quickly than in the past. Essel currently obtains its raw materials from four suppliers. Each of these suppliers operates differently in terms of the processes which they adopt in trading with Essel. Essel has been agreeable to this, as the quality of the raw material supplied has generally been acceptable. More recently, however, Essel has found reason to question the accuracy and quality of the raw material delivered from one supplier. Additionally, another supplier now only despatches material to ssel in full-load quantities as its wishes to optimize the use of its delivery vehicles. Current production methods The performance metric at Essel for production efficiency is the number of dresses produced per period. Essel's method of production is to produce individual dresses in long production runs which has helped in maximizing output. Staff working in the production department have their bonuses based on this metric. Essel has a practice of testing goods at the final stage of production and before they leave the factory. Goods which have not been produced according to required standard have traditionally been rejected at the end of the production process. Essel's production control manager has indicated to you that the current production methods have been successful, as the company only has 6% of all its goods returned from Crossland for quality-related reasons. Just-in-time (JIT) Costs of Conformance: Crossland would like to move to just-in-time (JIT) system of purchasing its goods from Essel and as a result Essel is contemplating major changes to its working practices. Essel's CEO has asked you, as a management accountant, to assess the changes which Essel will have to make in the areas of purchasing and production in order to supply goods to Crossland on a JIT basis. Costs of Quality Essel's CEO has also made available to you a cost of quality report which she believes addresses all relevant costs of quality. This report is show in Table 1X, below. He would like you to discuss the potential quality cost changes in light of the proposed move to JIT. He indicated that some of these costs have never been measured before and have been given financial values to help you in your discussion. He also told you that Essel's current revenue is R90 million. Table 1X: Prevention costs: Preventive maintenance Total Appraisal costs: Quality control supervisor Quality audits Total Costs of non-conformance: Internal failure costs: Rework cost Downtime due to quality problems Scrap Total External failure costs: Cost of complaints from Crossland Foregone contribution from lost sales* Product recalls and cost of goods returned Total Grand total R 100 000 710 000 100 000 1 440 000 760 000 1 160 000 2 700 000 1 700 000 3 600 000 (20 Marks) R (8 marks) 100 000 810 000 3 360 000 8 000 000 12 270 000 % of revenue (R90m) 0.11% 0.90% 3.73% 8.89% 13.63%

Step by Step Solution

★★★★★

3.47 Rating (154 Votes )

There are 3 Steps involved in it

Step: 1

To provide a detailed report on the potential changes in costs of quality for Essel in response to transitioning to a JIT system for supplying goods t...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started