Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Cultivation of a filamentous fungus in shake flasks and laboratory airlift bioreactor Your report contains two main parts: Materials and methods and Results and discussion

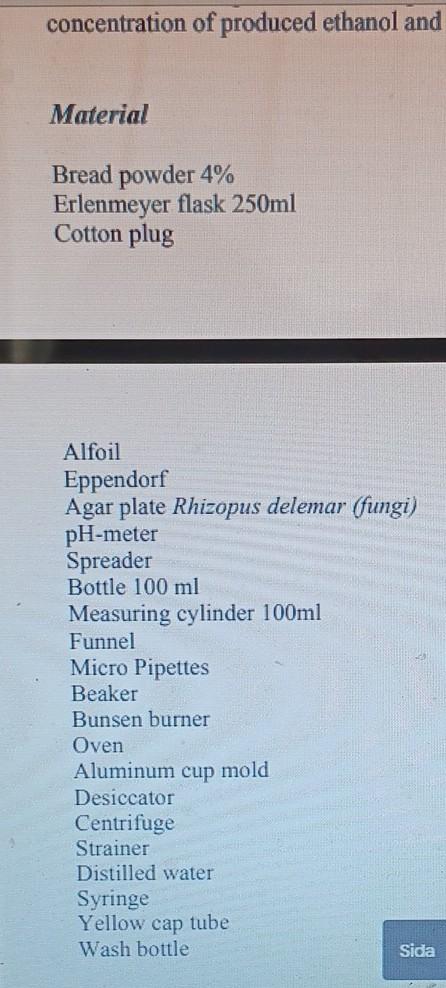

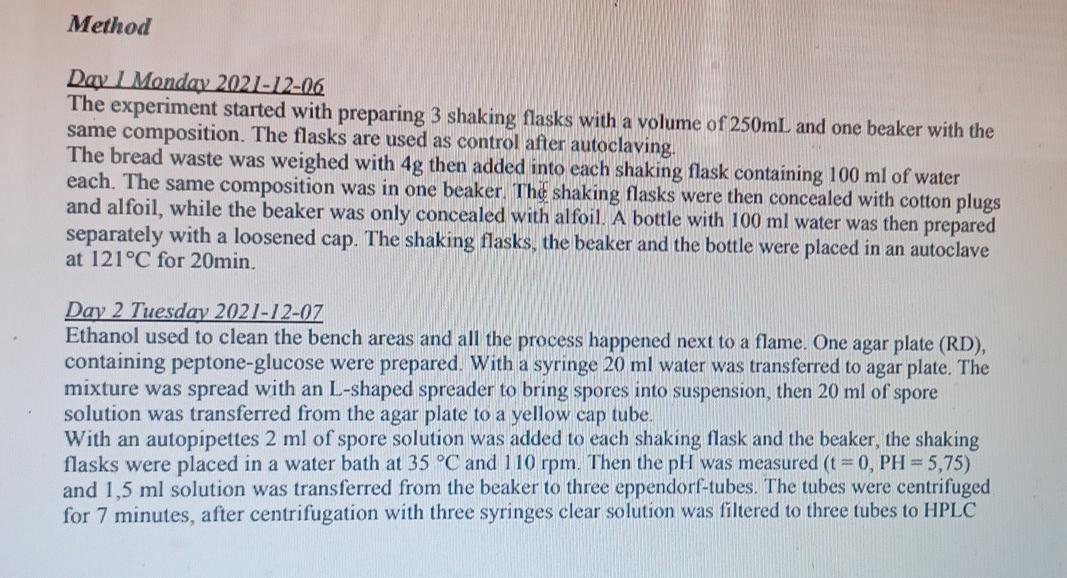

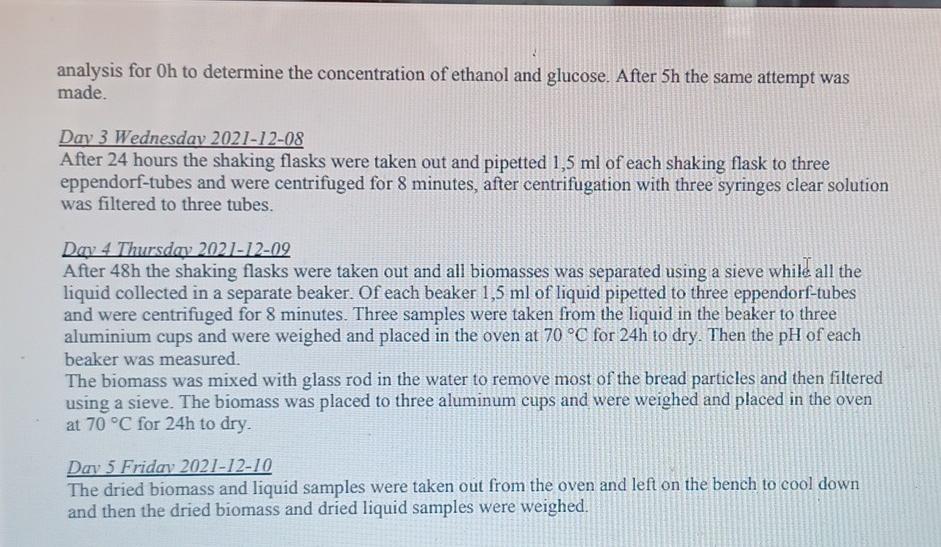

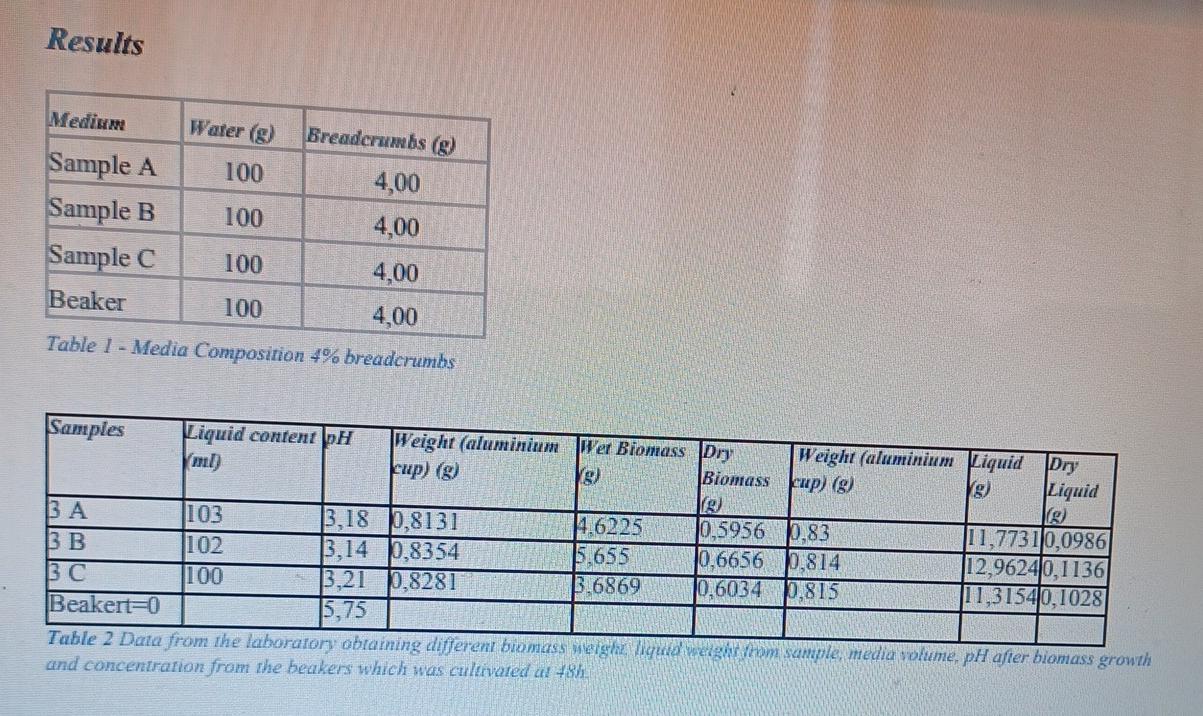

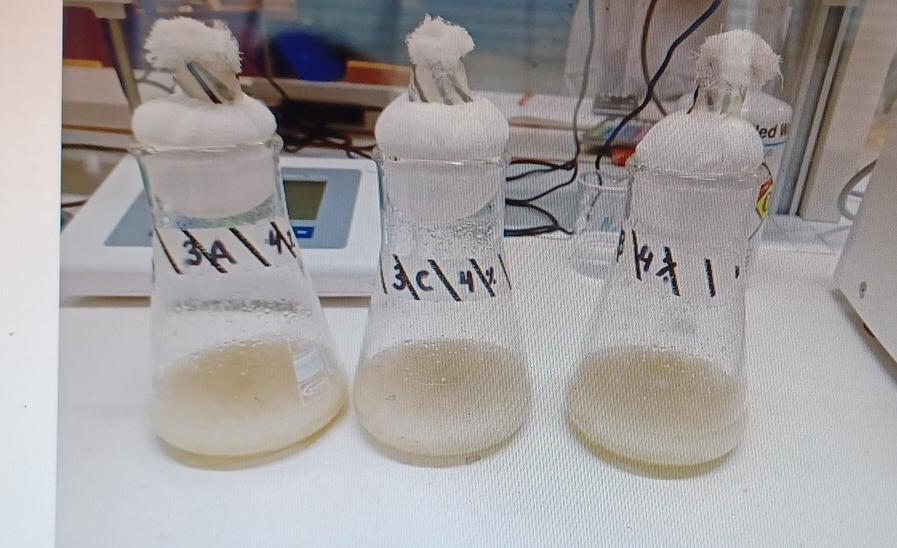

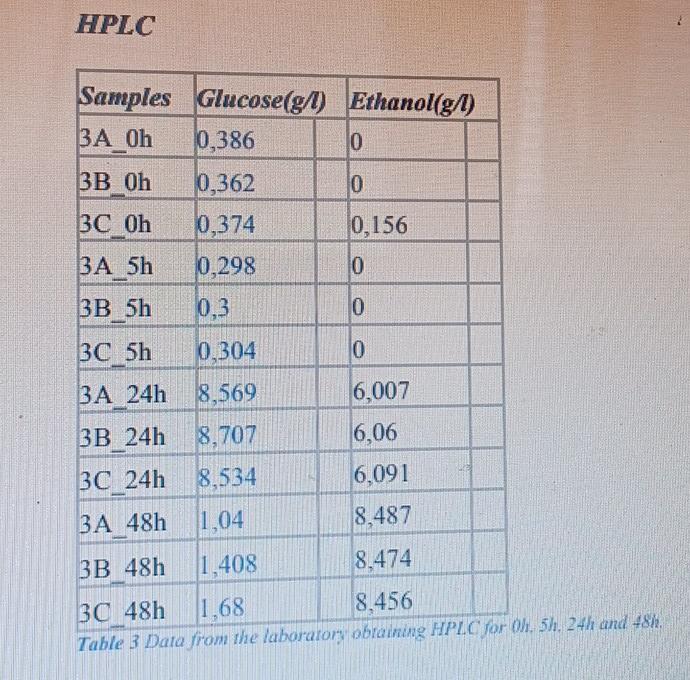

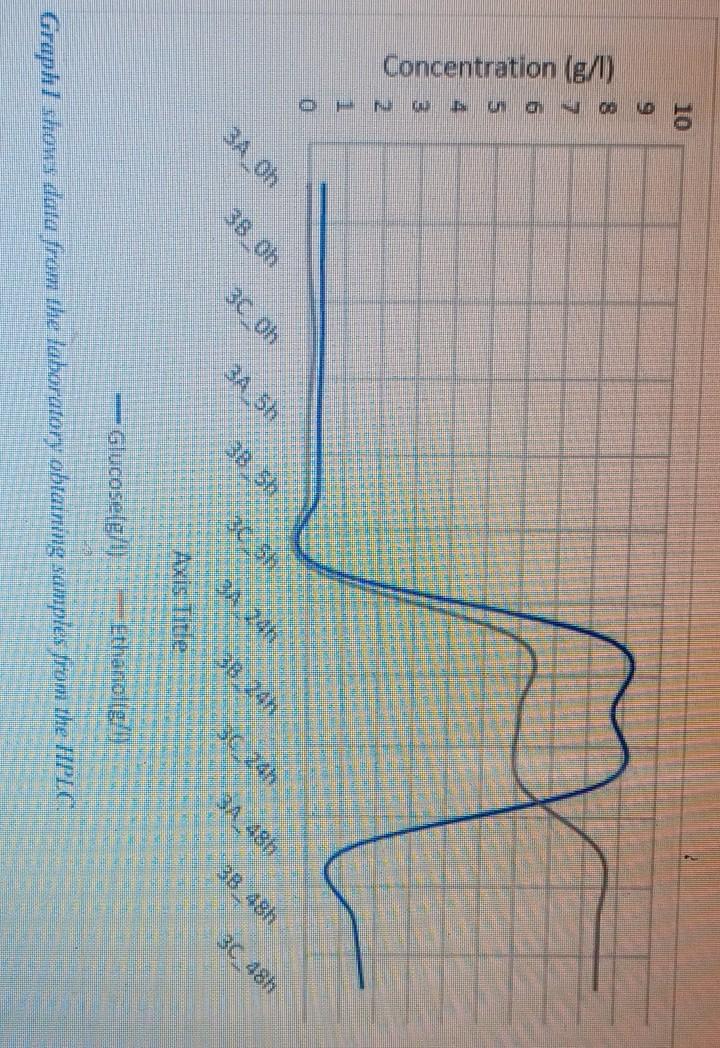

"Cultivation of a filamentous fungus in shake flasks and laboratory airlift bioreactor" Your report contains two main parts: "Materials and methods" and "Results and discussion" In Materials and methods, you should describe all details of how you did the experiment including preparation of culture medium, preparation of inoculum, sterilization, inoculation, sampling, measurements, etc. You also should write the details of each materials/chemicals that you used in your experiment. In the Results and discussion section, you need to describe all details about the results you have achieved. Additionally, you need to discuss your results and explain if the results are in agreement with your expectation or not. In this section, you should present the profiles of the ethanol and sugar, fungal biomass concentrations, the morphology of the fungus, and the yield and productivity of ethanol and fungal biomass. You should also argue that which phases of growth has happened during your experiment. Cultivation of a filamentous fungus in shake flasks and a laboratory airlift bioreactor Skr brdet i bitar och torkas i rumstemperatur i 2-3 dagar, drefter maldes till strbrd. Frvaras i frys tills anvndning. Brdmediet bereddes i duplikat genom att tillstta 10 g torkat och malt brd till 200 ml Milli-Q vatten, fljt av sterilisering i en autoklav i 20 minuter vid 121 C. och fyra 5 L- flaskor med Milli-Q-vatten steriliserades i 2 timmar vid 121 C. Flaskan inokulerades med 4 ml av sporsuspensionen och inkuberades i ett skakande vattenbad vid 35 C under 2 dagar. Fr att odla fungi vi behver agar plattor innehller (agar + glukos + pepton pH=5.5) i 4 dagar vid 35C. Sporsuspension frberedes genom att tillsats 20 ml MQ vatten till varje agarplatta med fungi. Det steriliserade brdet och vattnet blandades med 300 ml pre-inokulum av Fungi och odlades i 24 timmar i tv shake-flaskor innehllande 100 ml av vatten-brdsuspensionen vardera. Mediet verfrdes till bioreaktorn och odlingen krdes i 48 timmar vid 35 C. Vi behver stta in Luftningen p antingen 1 eller 1,42 wm. Efter 48 timmar, pumpas ut suspensionen av biomassa och medium frn bioreaktorn. Biomassan tvttas tv gngar med destillerat vatten. concentration of produced ethanol and Material Bread powder 4% Erlenmeyer flask 250ml Cotton plug Alfoil Eppendorf Agar plate Rhizopus delemar (fungi) pH-meter Spreader Bottle 100 ml Measuring cylinder 100ml Funnel Micro Pipettes Beaker Bunsen burner Oven Aluminum cup mold Desiccator Centrifuge Strainer Distilled water Syringe Yellow cap tube Wash bottle Sida Method Day I Monday 2021-12-06 The experiment started with preparing 3 shaking flasks with a volume of 250mL and one beaker with the same composition. The flasks are used as control after autoclaving, The bread waste was weighed with 4g then added into each shaking flask containing 100 ml of water each. The same composition was in one beaker. Th shaking flasks were then concealed with cotton plugs and alfoil, while the beaker was only concealed with alfoil. A bottle with 100 ml water was then prepared separately with a loosened cap. The shaking flasks, the beaker and the bottle were placed in an autoclave at 121C for 20min. Day 2 Tuesday 2021-12-07 Ethanol used to clean the bench areas and all the process happened next to a flame. One agar plate (RD), containing peptone-glucose were prepared. With a syringe 20 ml water was transferred to agar plate. The mixture was spread with an L-shaped spreader to bring spores into suspension, then 20 ml of spore solution was transferred from the agar plate to a yellow cap tube. With an autopipettes 2 ml of spore solution was added to each shaking flask and the beaker, the shaking flasks were placed in a water bath at 35 C and 110 rpm. Then the pH was measured (t = 0, PH = 5,75) and 1,5 ml solution was transferred from the beaker to three eppendorf-tubes. The tubes were centrifuged for 7 minutes, after centrifugation with three syringes clear solution was filtered to three tubes to HPLC analysis for Oh to determine the concentration of ethanol and glucose. After 5h the same attempt was made. Day 3 Wednesday 2021-12-08 After 24 hours the shaking flasks were taken out and pipetted 1,5 ml of each shaking flask to three eppendorf-tubes and were centrifuged for 8 minutes, after centrifugation with three syringes clear solution was filtered to three tubes. Day 4 Thursday 2021-12-09 After 48h the shaking flasks were taken out and all biomasses was separated using a sieve while all the liquid collected in a separate beaker. Of each beaker 1,5 ml of liquid pipetted to three eppendorf-tubes and were centrifuged for 8 minutes. Three samples were taken from the liquid in the beaker to three aluminium cups and were weighed and placed in the oven at 70 C for 24h to dry. Then the pH of each beaker was measured. The biomass was mixed with glass rod in the water to remove most of the bread particles and then filtered using a sieve. The biomass was placed to three aluminum cups and were weighed and placed in the oven at 70 C for 24h to dry. Dav 5 Friday 2021-12-10 The dried biomass and liquid samples were taken out from the oven and left on the bench to cool down and then the dried biomass and dried liquid samples were weighed. Results Water (g) Mediane Breadcrumbs (8) Sample A 100 4,00 Sample B 100 4,00 Sample C 100 4,00 Beaker 100 4,00 Table 1 - Media Composition 4% breadcrumbs Samples Liquid content pH Weight (aluminium Wer Biomass Dry Weight (aluminium Liquid Dry ml) cup) (g) 18) Biomass cup) (8) (9) Liquid Ig) g) 103 13,18 0,8131 4.6225 0,5956 0.83 111,77310,0986 BB 102 3,14 0,8354 5.655 10.6656 0,814 12,96240.1136 100 3,21 0,8281 B.6869 0.6034 0.815 11,31540,1028 Beakert=0 15.75 Table 2 Data from the laboratory obtaining different biomass weigh Mid Weight om sample, media volume, pH after biomass growth and concentration from the beakers which was cultivated at +861. ed (14\ (ackN/ 11 The dried biomass an HPLC Samples Glucose(g/l) Ethanol(g/) 3A Oh 0.386 0 3B Oh 0.362 10 30 Oh 0.374 0.156 3A Sh 0.298 10 3B 5h 0.3 0 3C Sh 0.304 0 3A 24h 8.569 6,007 3B 24h 8.707 6.06 3C 24h 18.534 6.091 3A 48h 11.04 8.487 3B 48h ! 408 8.474 30 48h 1.68 8.456 Table 3 Duratam the laborator abiurame Sida 59 HPLC Samples Glucose(g) Ethanol(g /1 BA Oh 0,386 0 BB Oh 0,362 10 3C Oh 0,374 0,156 3A 5h 0.298 0 3B 5h 10,3 0 3C5h 0.304 10 3A 24h 8,569 6,007 3B 24h 8.707 6,06 3C 24h 8,534 6,091 3A 48h 1,04 8,487 3B 48h 1,408 8,474 30 48h 1,68 8.456 Table 3 Data from the laboratory obraining HPLC for O. 5h. 24h and 48% 10 on 9 Concentration (g/l) ON A 000 3A. Oh 30 oh 30_24h . E 3A_485 3B 48h 38 oh 3A 5h 38,5h 3C 48h == Axis Title . Glucoselg/) Ethanolig?!) GraphI shows data from the laboratory obtaining samples from the HPLC

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started