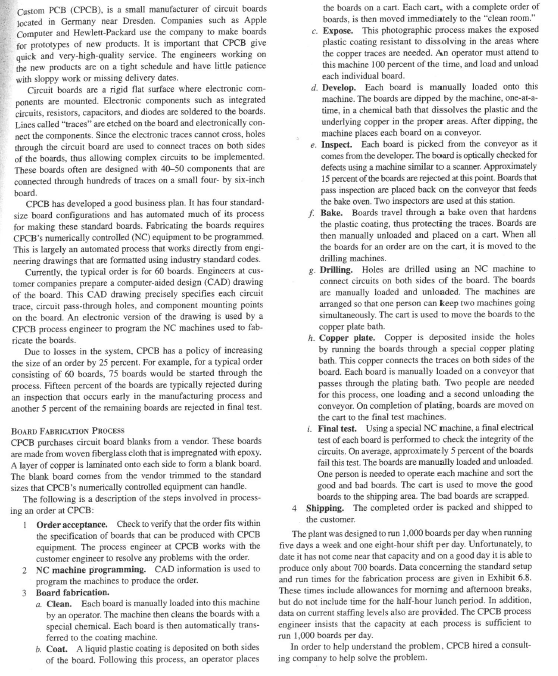

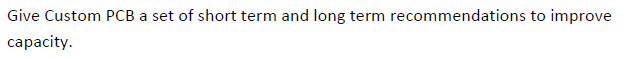

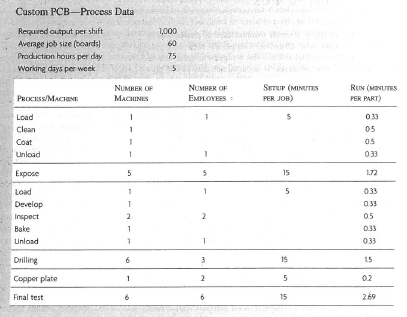

Custom PCB (CPCB), is a small manufacturer of circuit boards located in Germany near Dresden. Companies such as Apple Computer and Hewlett-Packard use the company to make boards for prototypes of new products. It is important that CPCB give quick and very high-quality service. The engineers working on the new products are on a tight schedule and have little patience with sloppy work or missing delivery dates Circuit boards are a rigid flat surface where electronic com ponents are mounted. Electronic components such as integrated circuits, resistors, capacitors, and diodes are soldered to the boards. Lines called "traces are etched on the board and electronically con- nect the components. Since the electronic traces cannot cross, holes through the circuit board are used to connect traces on both sides of the boards, thus allowing complex circuits to be implemented These boards often are designed with 40-50 components that are connected through hundreds of traces on a small four-by six-inch board. CPCB has developed a good business plan. It has four standard size board configurations and has automated much of its process for making these standard boards. Fabricating the boards requires CPCB's numerically controlled (NC) equipment to be programmed. This is largely an automated process that works directly from engi- neering drawings that are formatted using industry standard codes. Currently, the typical order is for 60 boards. Engineers at cus. tomer companies prepare a computer-aided design (CAD) drawing of the board. This CAD drawing precisely specifies each circuit trace, circuit pass through holes, and component mounting points on the board. An electronic version of the drawing is used by a CPCB process engineer to program the NC machines used to fab ricate the boards. Due to losses in the system, CPCB has a policy of increasing the size of an order by 25 percent. For example, for a typical order consisting of 60 boards, 75 boards would be started through the process. Fifteen percent of the boards are typically rejected during an inspection that occurs early in the manufacturing process and another 5 percent of the remaining boards are rejected in final test. the boards on a cart. Each cart, with a complete order of boards, is then moved immediately to the "clean room." c. Expose. This photographic process makes the exposed plastic coating resistant to dissolving in the areas where the copper traces are needed. An operator must attend to this machine 100 percent of the time, and load and unload each individual board. d. Develop. Each board is manually loaded onto this machine. The boards are dipped by the machine, one-al-- time, in a chemical bath that dissolves the plastic and the underlying copper in the proper areas. After dipping, the machine places each board on a conveyor. 6. Inspect. Each board is picked from the conveyor as it comes from the developer. The board is optically checked for defects using a machine similar to a scanner. Approximately 15 percent of the boards are rejected at this point. Boards that pass inspection are placed back on the conveyor that feeds the bake oven. Two inspectors are used at this station. 4. Bake. Boards travel through a bake oven that hardens the plastic coating, thus protecting the traces. Boards are then manually unloaded and placed on a cart, When all the boards for an order are on the cart, it is moved to the drilling machines g. Drilling. Holes are drilled using an NC machine to connect circuits on both sides of the board. The boards are manually loaded and unloaded. The machines are arranged so that one person can keep two machines going simultaneously. The cart is used to move the boards to the copper plate bath h. Copper plate. Copper is deposited inside the holes by running the boards through a special copper plating bath. This copper connects the traces on both sides of the board. Each board is manually loaded on a conveyor that passes through the plating bath. Two people are needed for this process, one loading and a second unloading the conveyor. On completion of plating, boards are moved on the cart to the final test machines. 1. Final test. Using a special NC machine, a final electrical test of each board is performed to check the integrity of the circuits. On average, approximately 5 percent of the boards fail this test. The boards are manually loaded and unloaded. One person is needed to operate each machine and sort the good and bad boards. The cart is used to move the good boards to the shipping area. The bad boards are scrapped. 4 Shipping. The completed order is packed and shipped to the customer The plant was designed to run 1.000 boards per day when running five days a week and one eight-hour shift per day. Unfortunately, to date it has not come near that capacity and on a good day it is able to produce only about 700 boards. Data concerning the standard setup and run times for the fabrication process are given in Exhibit 6.8. These times include allowances for morning and afternoon breaks, but do not include time for the half-hour lunch period. In addition, data on current staffing levels also are provided. The CPCB process engineer insists that the capacity at each process is sufficient to run 1,000 boards per day. In order to help understand the problem. CPCB hired a consult- ing company to help solve the problem. BOARD FABRICATION PROCESS CPCB purchases circuit board blanks from a vendor. These boards are made from woven fiberglass cloth that is impregnated with epoxy. A layer of copper is laminated onto each side to form a blank board The blank board comes from the vendor trimmed to the standard sizes that CPCB's numerically controlled equipment can handle. The following is a description of the steps involved in process ing an order at CPCB: Order acceptance. Check to verify that the order fits within the specification of boards that can be produced with CPCB equipment. The process engineer at CPCB works with the customer engineer to resolve any problems with the order 2 NC machine programming CAD information is used to program the machines to produce the order. 3 Board fabrication. a Clean. Each board is manually loaded into this machine by an operator. The machine then cleans the boards with a special chemical. Each board is then automatically trans- ferred to the coating machine. b. Coat. Aliquid plastic coating is deposited on both sides of the board. Following this process, an operator places 1,000 60 75 5 Custom PCB-Process Data Required output per shift Average job size boards] Production hours per day Working days per week NUMBER OF PROCESS/MACHINE MACHINES Load Clean Coat 1 Unload 1 Expose 5 NUMBER OF EMPLOYEES SETUP (MINUTES PER JOB) RUN (MINUTES PER PART) 033 05 05 033 1 5 15 1.72 1 5 Load Develop Inspect Bake Unload 1 2 2 033 0.33 0.5 0:33 033 1 1 Drilling 6 3 15 15 Copper plate 1 2 5 0.2 Final test 6 15 2.69 Give Custom PCB a set of short term and long term recommendations to improve capacity. Custom PCB (CPCB), is a small manufacturer of circuit boards located in Germany near Dresden. Companies such as Apple Computer and Hewlett-Packard use the company to make boards for prototypes of new products. It is important that CPCB give quick and very high-quality service. The engineers working on the new products are on a tight schedule and have little patience with sloppy work or missing delivery dates Circuit boards are a rigid flat surface where electronic com ponents are mounted. Electronic components such as integrated circuits, resistors, capacitors, and diodes are soldered to the boards. Lines called "traces are etched on the board and electronically con- nect the components. Since the electronic traces cannot cross, holes through the circuit board are used to connect traces on both sides of the boards, thus allowing complex circuits to be implemented These boards often are designed with 40-50 components that are connected through hundreds of traces on a small four-by six-inch board. CPCB has developed a good business plan. It has four standard size board configurations and has automated much of its process for making these standard boards. Fabricating the boards requires CPCB's numerically controlled (NC) equipment to be programmed. This is largely an automated process that works directly from engi- neering drawings that are formatted using industry standard codes. Currently, the typical order is for 60 boards. Engineers at cus. tomer companies prepare a computer-aided design (CAD) drawing of the board. This CAD drawing precisely specifies each circuit trace, circuit pass through holes, and component mounting points on the board. An electronic version of the drawing is used by a CPCB process engineer to program the NC machines used to fab ricate the boards. Due to losses in the system, CPCB has a policy of increasing the size of an order by 25 percent. For example, for a typical order consisting of 60 boards, 75 boards would be started through the process. Fifteen percent of the boards are typically rejected during an inspection that occurs early in the manufacturing process and another 5 percent of the remaining boards are rejected in final test. the boards on a cart. Each cart, with a complete order of boards, is then moved immediately to the "clean room." c. Expose. This photographic process makes the exposed plastic coating resistant to dissolving in the areas where the copper traces are needed. An operator must attend to this machine 100 percent of the time, and load and unload each individual board. d. Develop. Each board is manually loaded onto this machine. The boards are dipped by the machine, one-al-- time, in a chemical bath that dissolves the plastic and the underlying copper in the proper areas. After dipping, the machine places each board on a conveyor. 6. Inspect. Each board is picked from the conveyor as it comes from the developer. The board is optically checked for defects using a machine similar to a scanner. Approximately 15 percent of the boards are rejected at this point. Boards that pass inspection are placed back on the conveyor that feeds the bake oven. Two inspectors are used at this station. 4. Bake. Boards travel through a bake oven that hardens the plastic coating, thus protecting the traces. Boards are then manually unloaded and placed on a cart, When all the boards for an order are on the cart, it is moved to the drilling machines g. Drilling. Holes are drilled using an NC machine to connect circuits on both sides of the board. The boards are manually loaded and unloaded. The machines are arranged so that one person can keep two machines going simultaneously. The cart is used to move the boards to the copper plate bath h. Copper plate. Copper is deposited inside the holes by running the boards through a special copper plating bath. This copper connects the traces on both sides of the board. Each board is manually loaded on a conveyor that passes through the plating bath. Two people are needed for this process, one loading and a second unloading the conveyor. On completion of plating, boards are moved on the cart to the final test machines. 1. Final test. Using a special NC machine, a final electrical test of each board is performed to check the integrity of the circuits. On average, approximately 5 percent of the boards fail this test. The boards are manually loaded and unloaded. One person is needed to operate each machine and sort the good and bad boards. The cart is used to move the good boards to the shipping area. The bad boards are scrapped. 4 Shipping. The completed order is packed and shipped to the customer The plant was designed to run 1.000 boards per day when running five days a week and one eight-hour shift per day. Unfortunately, to date it has not come near that capacity and on a good day it is able to produce only about 700 boards. Data concerning the standard setup and run times for the fabrication process are given in Exhibit 6.8. These times include allowances for morning and afternoon breaks, but do not include time for the half-hour lunch period. In addition, data on current staffing levels also are provided. The CPCB process engineer insists that the capacity at each process is sufficient to run 1,000 boards per day. In order to help understand the problem. CPCB hired a consult- ing company to help solve the problem. BOARD FABRICATION PROCESS CPCB purchases circuit board blanks from a vendor. These boards are made from woven fiberglass cloth that is impregnated with epoxy. A layer of copper is laminated onto each side to form a blank board The blank board comes from the vendor trimmed to the standard sizes that CPCB's numerically controlled equipment can handle. The following is a description of the steps involved in process ing an order at CPCB: Order acceptance. Check to verify that the order fits within the specification of boards that can be produced with CPCB equipment. The process engineer at CPCB works with the customer engineer to resolve any problems with the order 2 NC machine programming CAD information is used to program the machines to produce the order. 3 Board fabrication. a Clean. Each board is manually loaded into this machine by an operator. The machine then cleans the boards with a special chemical. Each board is then automatically trans- ferred to the coating machine. b. Coat. Aliquid plastic coating is deposited on both sides of the board. Following this process, an operator places 1,000 60 75 5 Custom PCB-Process Data Required output per shift Average job size boards] Production hours per day Working days per week NUMBER OF PROCESS/MACHINE MACHINES Load Clean Coat 1 Unload 1 Expose 5 NUMBER OF EMPLOYEES SETUP (MINUTES PER JOB) RUN (MINUTES PER PART) 033 05 05 033 1 5 15 1.72 1 5 Load Develop Inspect Bake Unload 1 2 2 033 0.33 0.5 0:33 033 1 1 Drilling 6 3 15 15 Copper plate 1 2 5 0.2 Final test 6 15 2.69 Give Custom PCB a set of short term and long term recommendations to improve capacity