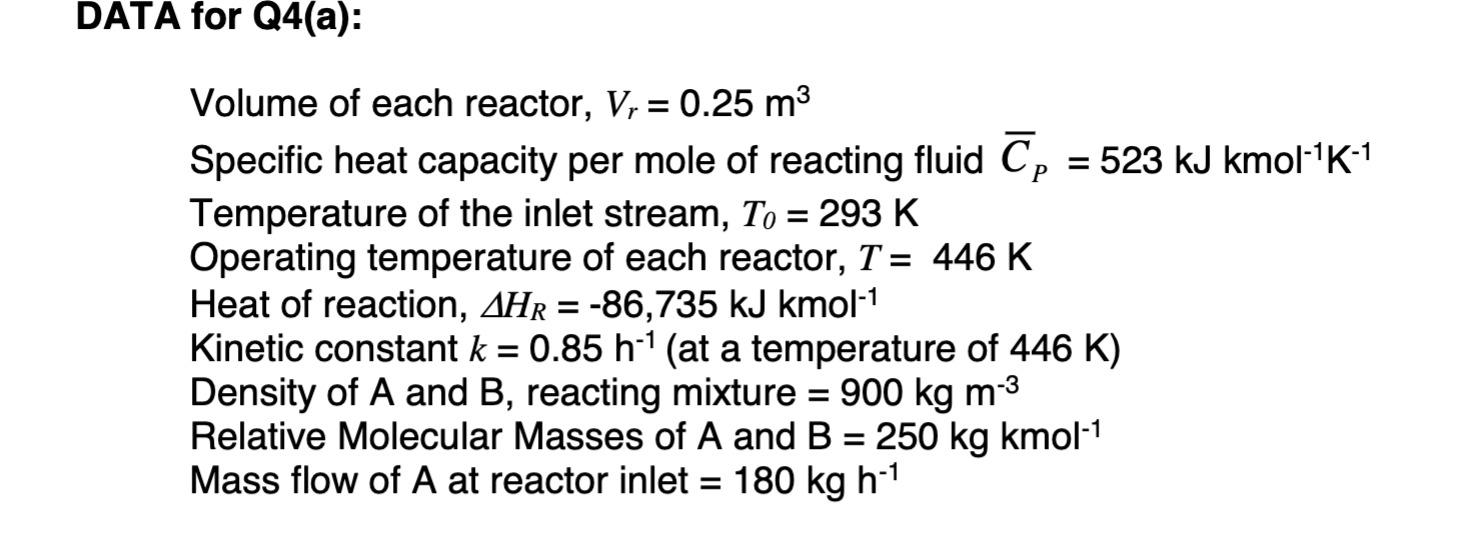

Question: DATA for Q4(a): = = Volume of each reactor, Vr = 0.25 m3 Specific heat capacity per mole of reacting fluid Tp = 523 kJ

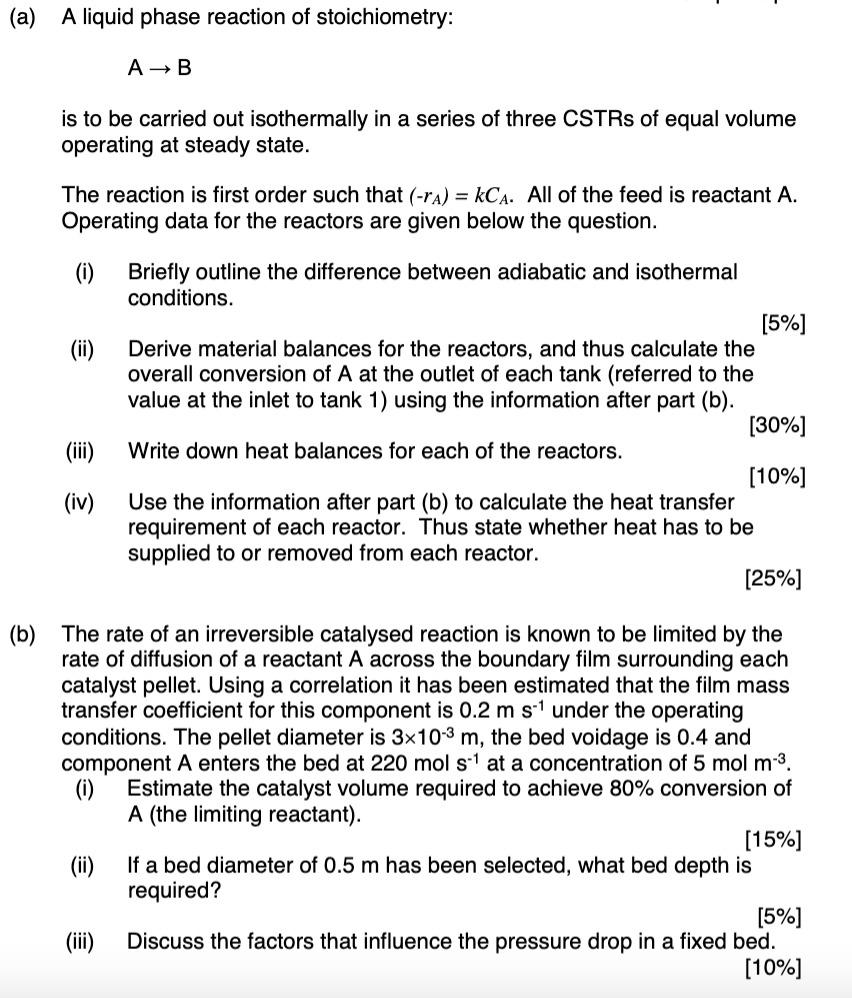

DATA for Q4(a): = = Volume of each reactor, Vr = 0.25 m3 Specific heat capacity per mole of reacting fluid Tp = 523 kJ kmol-1K-1 Temperature of the inlet stream, To = 293 K Operating temperature of each reactor, T = 446 K Heat of reaction, AHR = -86,735 kJ kmol-1 Kinetic constant k = 0.85 h-(at a temperature of 446 K) Density of A and B, reacting mixture = 900 kg m-3 Relative Molecular Masses of A and B = 250 kg kmol-1 Mass flow of A at reactor inlet = 180 kg h-1 = = = = (a) A liquid phase reaction of stoichiometry: AB is to be carried out isothermally in a series of three CSTRs of equal volume operating at steady state. The reaction is first order such that (-ra) = kCA. All of the feed is reactant A. Operating data for the reactors are given below the question. (1) (ii) Briefly outline the difference between adiabatic and isothermal conditions. [5%] Derive material balances for the reactors, and thus calculate the overall conversion of A at the outlet of each tank (referred to the value at the inlet to tank 1) using the information after part (b). [30%] Write down heat balances for each of the reactors. (10%) Use the information after part (b) to calculate the heat transfer requirement of each reactor. Thus state whether heat has to be supplied to or removed from each reactor. [25%) (iii) (iv) (b) The rate of an irreversible catalysed reaction is known to be limited by the rate of diffusion of a reactant A across the boundary film surrounding each catalyst pellet. Using a correlation it has been estimated that the film mass transfer coefficient for this component is 0.2 m s' under the operating conditions. The pellet diameter is 3x10-3 m, the bed voidage is 0.4 and component A enters the bed at 220 mol s1 at a concentration of 5 mol m 3. (i) Estimate the catalyst volume required to achieve 80% conversion of A (the limiting reactant). [15%] (ii) If a bed diameter of 0.5 m has been selected, what bed depth is required? [5%) (iii) Discuss the factors that influence the pressure drop in a fixed bed. (10%) DATA for Q4(a): = = Volume of each reactor, Vr = 0.25 m3 Specific heat capacity per mole of reacting fluid Tp = 523 kJ kmol-1K-1 Temperature of the inlet stream, To = 293 K Operating temperature of each reactor, T = 446 K Heat of reaction, AHR = -86,735 kJ kmol-1 Kinetic constant k = 0.85 h-(at a temperature of 446 K) Density of A and B, reacting mixture = 900 kg m-3 Relative Molecular Masses of A and B = 250 kg kmol-1 Mass flow of A at reactor inlet = 180 kg h-1 = = = = (a) A liquid phase reaction of stoichiometry: AB is to be carried out isothermally in a series of three CSTRs of equal volume operating at steady state. The reaction is first order such that (-ra) = kCA. All of the feed is reactant A. Operating data for the reactors are given below the question. (1) (ii) Briefly outline the difference between adiabatic and isothermal conditions. [5%] Derive material balances for the reactors, and thus calculate the overall conversion of A at the outlet of each tank (referred to the value at the inlet to tank 1) using the information after part (b). [30%] Write down heat balances for each of the reactors. (10%) Use the information after part (b) to calculate the heat transfer requirement of each reactor. Thus state whether heat has to be supplied to or removed from each reactor. [25%) (iii) (iv) (b) The rate of an irreversible catalysed reaction is known to be limited by the rate of diffusion of a reactant A across the boundary film surrounding each catalyst pellet. Using a correlation it has been estimated that the film mass transfer coefficient for this component is 0.2 m s' under the operating conditions. The pellet diameter is 3x10-3 m, the bed voidage is 0.4 and component A enters the bed at 220 mol s1 at a concentration of 5 mol m 3. (i) Estimate the catalyst volume required to achieve 80% conversion of A (the limiting reactant). [15%] (ii) If a bed diameter of 0.5 m has been selected, what bed depth is required? [5%) (iii) Discuss the factors that influence the pressure drop in a fixed bed. (10%)

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts