Question

Dear Experts I need a help in this task, please. If possible also include the steps for solution using Solver. Thanks A factory is scheduling

Dear Experts I need a help in this task, please. If possible also include the steps for solution using Solver. Thanks

A factory is scheduling hiring staff for the months of March, April, and May, to work in the production department. Staff can work standard hours and overtime.

The standard hourly rate is $10 and the overtime is $15. The economic department of the factory has scheduled the following salaries to be paid in these months:

March: 2000 regular hours and 600 overtime hours

April: 1800 regular hours and 500 overtime hours

May: 2000 regular hours and 700 overtime hours

In each working hour (regular or overtime) two units of product are produced. The demand is expected to be 3800, 4200, and 4600 units for the months of March, April and May, respectively and the marketing department has set as requisite that this demand is satisfied each month. Initially, there is no stock at the end of February. If there is stock at the end of a month, it may be stored to meet the demand of the following months, with a monthly storage cost of $2 per unit.

No stock is allowed after the end of the three months, thus the end of May. What is the optimum number of regular and overtime hours for the months of March, April, and May, minimizing the total production and storage costs?

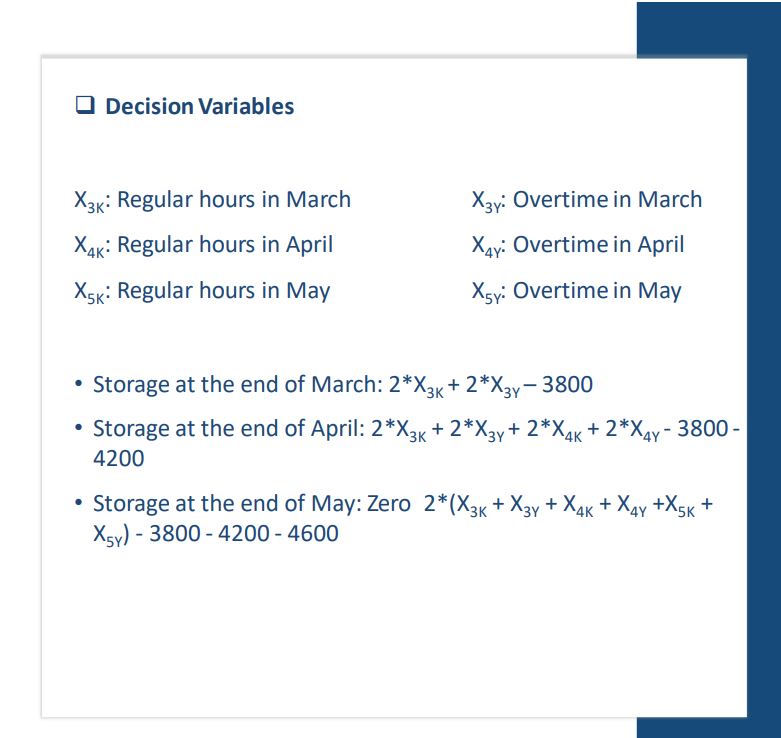

- Storage at the end of March: 2X3K+2X3Y3800 - Storage at the end of April: 2X3K+2X3Y+2X4K+2X4Y3800 4200 - Storage at the end of May: Zero 2(X3K+X3Y+X4K+X4Y+X5K+ X5Y ) - 3800-4200-4600

- Storage at the end of March: 2X3K+2X3Y3800 - Storage at the end of April: 2X3K+2X3Y+2X4K+2X4Y3800 4200 - Storage at the end of May: Zero 2(X3K+X3Y+X4K+X4Y+X5K+ X5Y ) - 3800-4200-4600 Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started