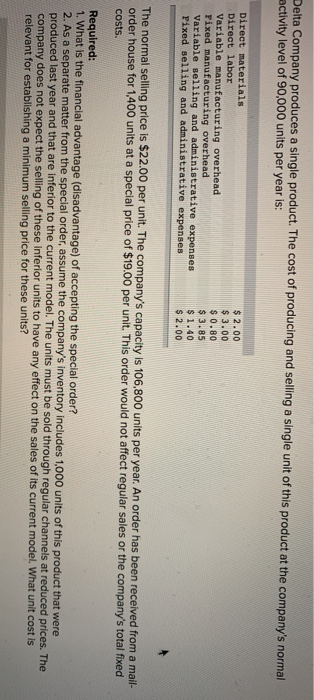

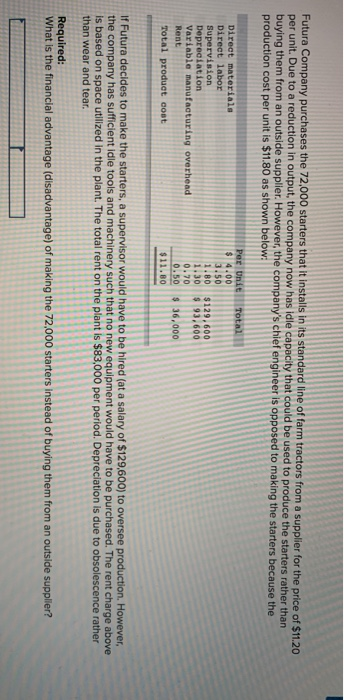

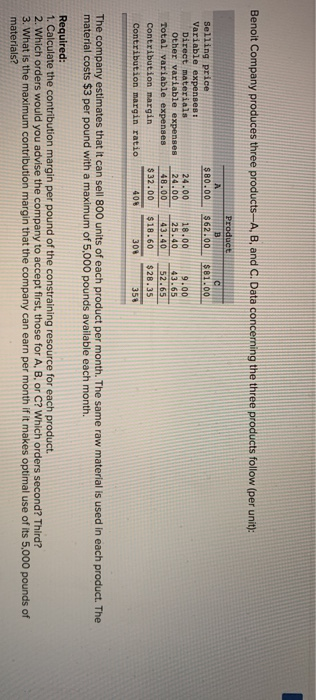

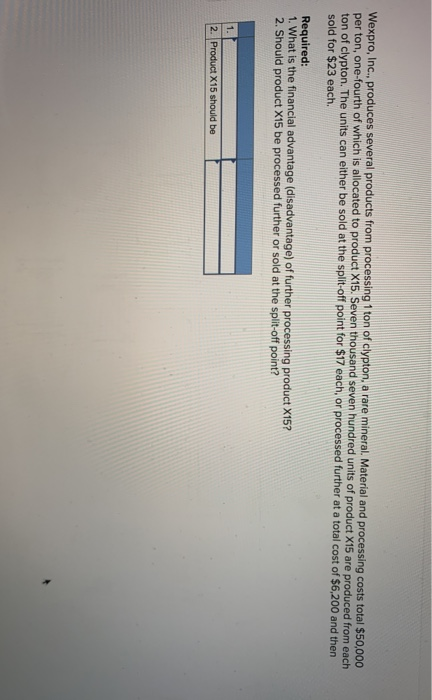

Delta Company produces a single product. The cost of producing and selling a single unit of this product at the company's normal activity level of 90,000 units per year is: Direct materials Direct labor Variable manufacturing overhead Fixed manufacturing overhead Variable selling and administrative expenses Fixed selling and administrative expenses $ 2.00 $ 3.00 $ 0.80 $ 3.85 $ 1.40 $ 2.00 The normal selling price is $22.00 per unit. The company's capacity is 106,800 units per year. An order has been received from a mail- order house for 1.400 units at a special price of $19.00 per unit. This order would not affect regular sales or the company's total fixed costs. Required: 1. What is the financial advantage (disadvantage) of accepting the special order? 2. As a separate matter from the special order, assume the company's Inventory includes 1,000 units of this product that were produced last year and that are inferior to the current model. The units must be sold through regular channels at reduced prices. The company does not expect the selling of these inferior units to have any effect on the sales of its current model. What unit cost is relevant for establishing a minimum selling price for these units? Futura Company purchases the 72,000 starters that it installs in its standard line of farm tractors from a supplier for the price of $11.20 per unit. Due to a reduction in output, the company now has idle capacity that could be used to produce the starters rather than buying them from an outside supplier. However, the company's chief engineer is opposed to making the starters because the production cost per unit is $11.80 as shown below: Direct materials Direct labor Supervision Depreciation Variable manufacturing overhead Rent Total product cost Per UnitTotal $ 4.00 3.50 1.80 $129,600 1.30 $ 93,600 0.70 0.50 $ 36,000 $11.30 If Futura decides to make the starters, a supervisor would have to be hired (at a salary of $129,600) to oversee production. However, the company has sufficient idle tools and machinery such that no new equipment would have to be purchased. The rent charge above is based on space utilized in the plant. The total rent on the plant is $83,000 per period. Depreciation is due to obsolescence rather than wear and tear. Required: What is the financial advantage (disadvantage) of making the 72,000 starters instead of buying them from an outside supplier? Benoit Company produces three products-A, B, and C. Data concerning the three products follow (per unit): Product AD $80.00 $62.00 $81.00 Selling price Variable expenses: Direct materials Other variable expenses Total variable expenses Contribution margin Contribution margin ratio 24.00 24.00 48.00 $32.00 18.00 9.00 25.40 43.65 43.405 2.65 $18.60 $28.35 356 The company estimates that it can sell 800 units of each product per month. The same raw material is used in each product. The material costs $3 per pound with a maximum of 5,000 pounds available each month. Required: 1. Calculate the contribution margin per pound of the constraining resource for each product. 2. Which orders would you advise the company to accept first, those for A, B. or C? Which orders second? Third? 3. What is the maximum contribution margin that the company can earn per month if it makes optimal use of its 5,000 pounds of materials? Wexpro, Inc., produces several products from processing 1 ton of clypton, a rare mineral. Material and processing costs total $50,000 per ton, one-fourth of which is allocated to product X15. Seven thousand seven hundred units of product X15 are produced from each ton of clypton. The units can either be sold at the split-off point for $17 each, or processed further at a total cost of $6,200 and then sold for $23 each. Required: 1. What is the financial advantage (disadvantage) of further processing product X15? 2. Should product X15 be processed further or sold at the split-off point? 2. Product X15 should be