Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Demand The company works on two shifts, each of eight hours, with a 3 0 minutes break for shift. The production family B is made

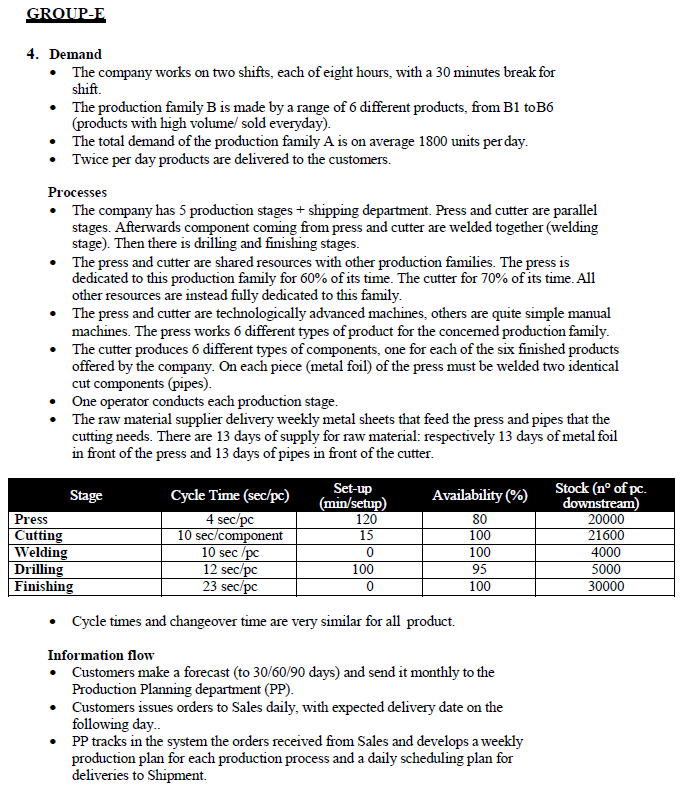

Demand

The company works on two shifts, each of eight hours, with a minutes break for

shift.

The production family B is made by a range of different products, from B toB

products with high volume sold everyday

The total demand of the production family A is on average units per day.

Twice per day products are delivered to the customers.

Processes

The company has production stages shipping department. Press and cutter are parallel

stages. Afterwards component coming from press and cutter are welded together welding

stage Then there is drilling and finishing stages.

The press and cutter are shared resources with other production families. The press is

dedicated to this production family for of its time. The cutter for of its time. All

other resources are instead fully dedicated to this family.

The press and cutter are technologically advanced machines, others are quite simple manual

machines. The press works different types of product for the concerned production family.

The cutter produces different types of components, one for each of the six finished products

offered by the company. On each piece metal foil of the press must be welded two identical

cut components pipes

One operator conducts each production stage.

The raw material supplier delivery weekly metal sheets that feed the press and pipes that the

cutting needs. There are days of supply for raw material: respectively days of metal foil

in front of the press and days of pipes in front of the cutter.

Cycle times and changeover time are very similar for all product.

Information flow

Customers make a forecast to days and send it monthly to the

Production Planning department PP

Customers issues orders to Sales daily, with expected delivery date on the

following day..

PP tracks in the system the orders received from Sales and develops a weekly

production plan for each production process and a daily scheduling plan for

deliveries to Shipment.

PP sends a forecast days to the supplier and confirms orders weekly.

a Create a Value Stream Map for the current state Provide all necessary data in VSMas

learned in the class and calculate the following:

iv Lead Time

v Value Added Time

vi Process Cycle Efficiency

b Based on the gap between customer demand and actual daily throughput:

Use WH Cause and Effect Diagram and why analysis to identify the root cause

of throughput loss. Start with the problem statement as: "Missing customer demand

due to throughput loss"

c Once Lean tool applied to identify the loss, provide recommendation to make overall

improvement and draw future State VSM

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started