Answered step by step

Verified Expert Solution

Question

1 Approved Answer

describe and explain the operation of the equipment used for load cycling on an avery Denison 4oo kN universal testing machine Fig 3.3 shows the

describe and explain the operation of the equipment used for load cycling on an avery Denison 4oo kN universal testing machine

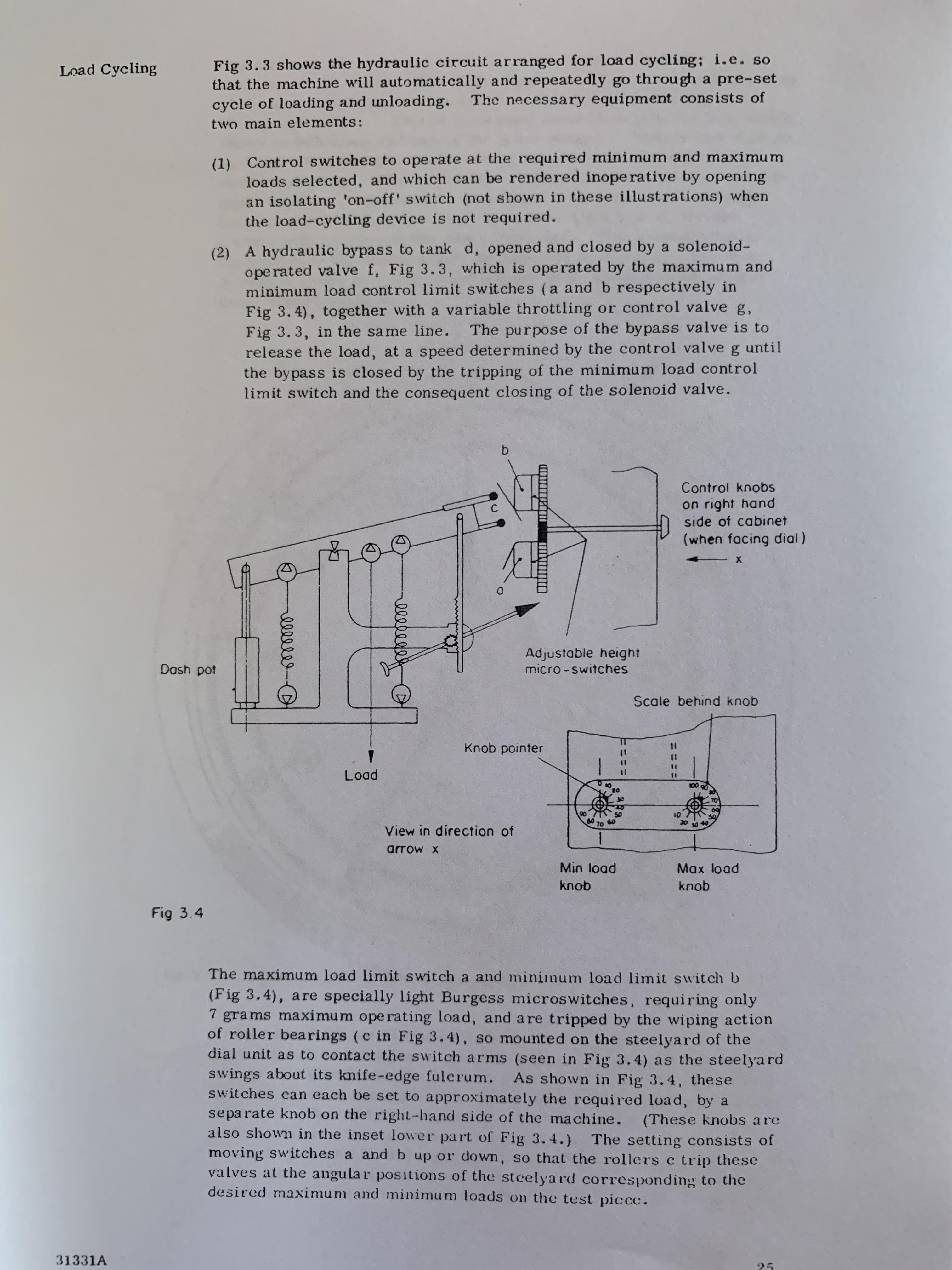

Fig 3.3 shows the hydraulic circuit arranged for load cycling; i.e. so that the machine will automatically and repeatedly go through a pre-set cycle of loading and unloading. Load Cycling The necessary equipment consists of two main elements: (1) Control switches to operate at the required minimum and maximum loads selected, and which can be rendered inoperative by opening an isolating 'on-off' switch (not shown in these illustrations) when the load-cycling device is not required. (2) A hydraulic bypass to tank d, opened and closed by a solenoid- ope rated valve f, Fig 3.3, which is operated by the maximum and minimum load control limit switches (a and b respectively in Fig 3. 4), together with a variable throttling or control valve g. Fig 3.3, in the same line. release the load, at a speed determined by the control valveg until the bypass is closed by the tripping of the minimum load control limit switch and the consequent closing of the solenoid valve. The purpose of the bypass valve is to Control knobs on right hand side of cabinet (when facing dial) Adjustable height micro -switches Dash pot Scale behind knob Knob pointer Load 10 60 70 20 30 View in direction of arrow x Min load Max load knob knob Fig 3.4 The maximum load limit switch a and minimum load limit switch b (Fig 3.4), are specially light Burgess microswitches, requiring only 7 gra ms maximum ope rating load, and a re tripped by the wiping action of roller bearings (c in Fig 3.4), so mounted on the steelyard of the dial unit as to contact the switch arms (seen in Fig 3.4) as the steelya rd swings about its knife-edge fulcrum. As shown in Fig 3.4, these switches can each be set to approximately the required load, by a separate knob on the right-hand side of the machine. also shown in the inset lower part of Fig 3.4.) moving switches a and b up or down, so that the rollers c trip these valves at the angular positions of the stcelyard corresponding to the desired maximum and minimum loads on the test piece. (These knobs are The setting consists of 31331A 25 ===D%3= ll ellll The bypass to tank d, Fig 3.3, is coupled up by flexible pipes, and is opened or closed by the action of the solenoid-ope rated piston valve, f in Fig 3.3, wbich is in turn controlled by the two Burgess microswitches, a and b, Fig 3.4. Since a release of load on a microswitch immediately makes or breaks contact, another microswitch is mounted on the solenoid valve to hold it in circuit until the microswitch at the other end of the load cycle operates. The load-cycling attachment is operated by first switching the load-cycle on-off switch from 'off' to the 'load-cycling' position. The maximum load knob and minimum load knob (see inset, Fig 3.4) are then set to the required approximate positions, as shown by the knob pointers on the The knob scales are marked in percentages of full load, and the actual percentages of load are shown on the bezel round the load-indicating The finer setting can be made when the loading and With the load-cycle control valve, scale. dial of the machine. unloading speeds have been adjusted. g in Fig 3.3 wide open, the machine is started with the specimen in position, the pump delive ry and fine straining controls (e and f, Fig 3.1) being adjusted to give the required loading speed, after which the load- cycle control valve is screwed down slowly, to give the required slower unloading speed. Care must be taken that the adjustment of the load-cycle control valve at a low flow limit is such that when the switch operates the load falls, and does not go on increasing to the maximum ma chine load because the pump If the load does not immediately delivery is greater than the return flow. return when the maximum load limit switch operates, either the pump delivery must be reduced or the fine straining control valve slightly An alternative is to open the load-cycle control valve slightly, opened. depending upon whether it is preferred to decrease the loading speed or increase the unloading speed. After test, the specimen is removed and a new one inserted. machine can then be left to load and unload the new specimen while the previous specimen is exa mined by strain gauges, etc. cycles is recorded by an electric counter, shown diagrammatically at i in Fig 3.3, fitted on the front of the machine. The overload precautions of the standard machine are not interfered with in any way, and operate The The number of The load-cycling mechanism is entirely independent. as usual. it is desired to operate the machine as a normal standard tester without using the load-cycling equipment, the maximum load limit switch is set to just beyond a hundred per cent, the minimum load limit switch is set to just below zero, and the load-cycle isolating switch is switched to 'off'. This setting of the load limit switches renders them inoperative. When

Step by Step Solution

★★★★★

3.37 Rating (163 Votes )

There are 3 Steps involved in it

Step: 1

Operation of the equipments to be used for load cycling on Avery Dennison 400kN UTM You need to refer fig 33 and 34 for further discription which I am ...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started