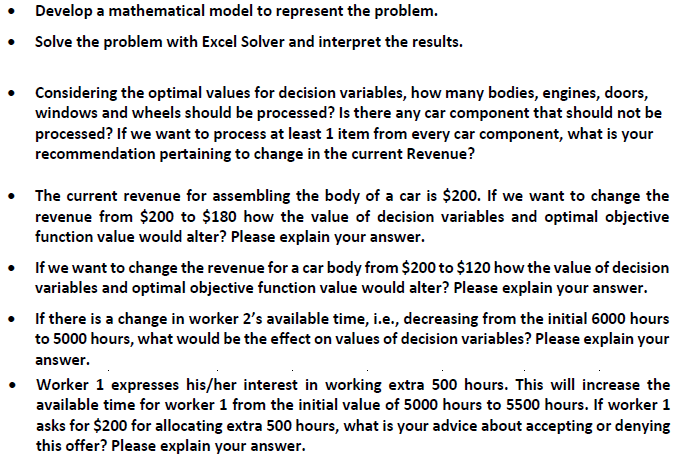

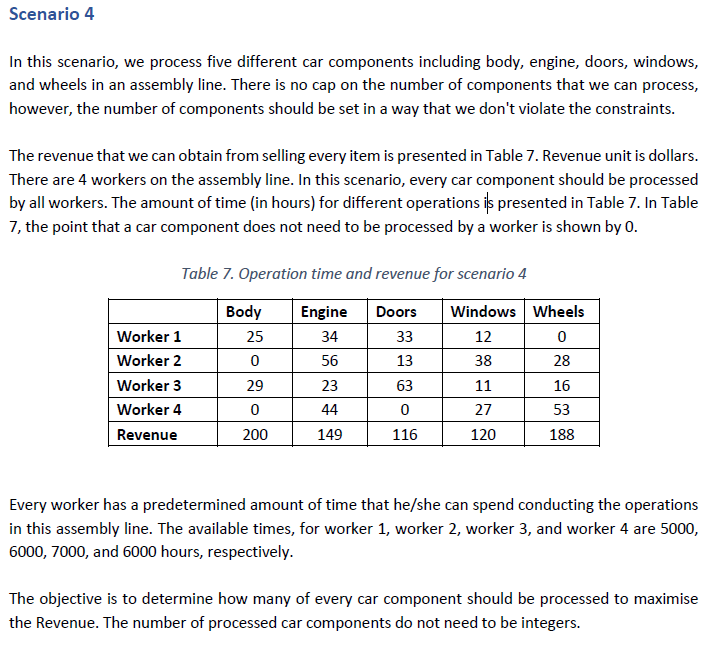

Develop a mathematical model to represent the problem. Solve the problem with Excel Solver and interpret the results. Considering the optimal values for decision variables, how many bodies, engines, doors, windows and wheels should be processed? Is there any car component that should not be processed? If we want to process at least 1 item from every car component, what is your recommendation pertaining to change in the current Revenue? The current revenue for assembling the body of a car is $200. If we want to change the revenue from $200 to $180 how the value of decision variables and optimal objective function value would alter? Please explain your answer. If we want to change the revenue for a car body from $200 to $120 howthe value of decision variables and optimal objective function value would alter? Please explain your answer. If there is a change in worker 2's available time, i.e., decreasing from the initial 6000 hours to 5000 hours, what would be the effect on values of decision variables? Please explain your answer. Worker 1 expresses hisj'her interest in working extra 500 hours. This will increase the available time for worker 1 from the initial value of 5000 hours to 5500 hours. If worker 1 asks for $200 for allocating extra 500 hours, what is your advice about accepting or denying this offer? Please explain your answer. Scenario 4 In this scenario, we process five different car components including body, engine, doors, windows, and wheels in an assembly line. There is no cap on the number of components that we can process, however, the number of components should be set in a way that we don't violate the constraints. The revenue that we can obtain from selling every item is presented in Table 7. Revenue unit is dollars. There are 4 workers on the assembly line. In this scenario, every car component should be processed by all workers. The amount of time (in hours) for different operations is presented in Table 7. In Table 7, the point that a car component does not need to be processed by a worker is shown by 0. Table 7. Operation time and revenue for scenario 4 Body Engine Doors Windows Wheels Worker 1 25 34 33 12 0 Worker 2 0 56 13 38 28 Worker 3 29 23 63 11 16 Worker 4 44 0 27 53 Revenue 200 149 116 120 188 Every worker has a predetermined amount of time that he/she can spend conducting the operations in this assembly line. The available times, for worker 1, worker 2, worker 3, and worker 4 are 5000, 6000, 7000, and 6000 hours, respectively. The objective is to determine how many of every car component should be processed to maximise the Revenue. The number of processed car components do not need to be integers