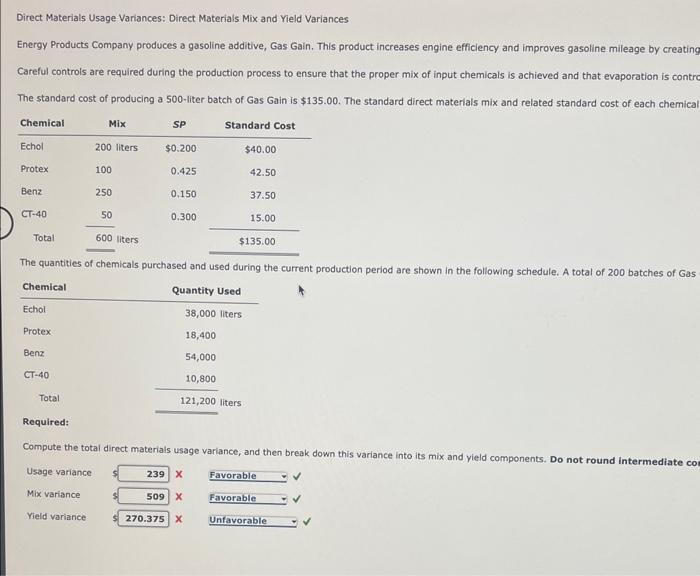

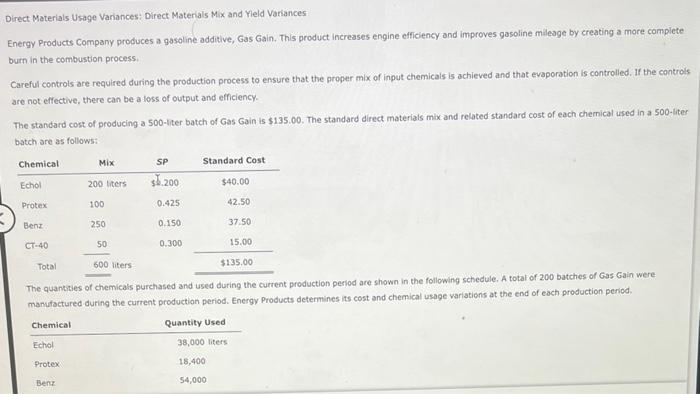

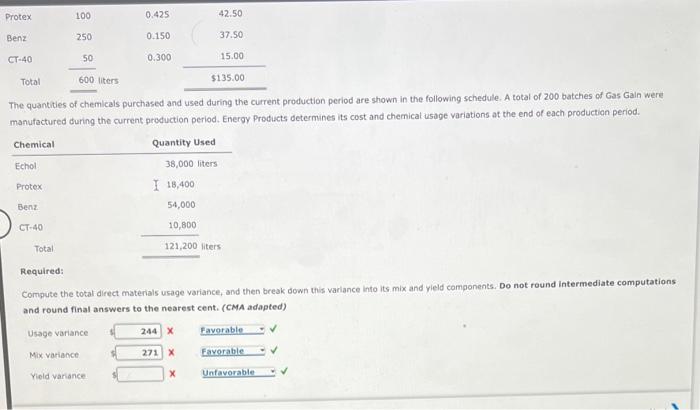

Direct Materials Usage Variances: Direct Materials Mix and Yield Variances Energy Products Company produces a gasoline additive, Gas Gain. This product increases engine efficiency and improves gasoline mileage by creating Careful controls are required during the production process to ensure that the proper mix of input chemicals is achieved and that evaporation is contri The standard cost of producing a 500 -liter batch of Gas Gain is $135.00. The standard direct materials mix and related standard cost of each chemical The quantities of chemicals purchased and used during the current production period are shown in the following schedule. A total of 200 batches of Gas Compute the total direct materials usage variance, and then break down this variance into its mix and yield components. Do not round intermediate co d Yield Variances Gas Gain, This product increases engine efficiency and improves gasoline milieage by creating a more complete burn in the combustion process. ess to ensure that the proper mix of input chemicals is achieved and that evaporation is controlled. If the controls are not effective, there can be a loss of output and efficiency. Gain is $135.00. The standard direct materials mix and related standard cost of each chemical used in a 500 -liter batch are as follows: the current production period are shown in the following schedule. A total of 200 batches of Gas Gain were manufactured during the current production period. Energy Products determi and then break down this variance into its mix and yeld components. Do not round intermediate computations and round tinat answers to the nearest cent. (CMA adopted) Uhe milesge by creating a more complete burn in the combustion process. that evaporation is controlled. If the controls are not effective, there can be a loss of output and elficiency. sed cost of each chemicat wsed in a 500 -itter batch are ac folions. A total of 200 butches of Cas Gain were manufactured during the current production period. Energy Products determi Do not round Intermediate computations and round final answers to the nearest cent. (CMA adapted) Direct Materials Usage Variances: Direct Materials Mix and Yleld Variances Energy Products Company produces a gasoline additive, Gas Gain. This product increases engine efficiency and improves gasoline mileage by creating a more complete butn in the combustion process. Careful controls are required during the production process to ensure that the proper mix of input chemicals is achieved and that evaporation is controlled. If the controls are not effective, there can be a loss of output and efficiency. The standard cost of producing a 500 -liter batch of Gas Gain is $135.00. The standard direct materials mix and related standard cost of each chernical used in a s00-liter batch are as follows: The quantites of chemicais purchased and used during the current production pertod are shown in the following schedule. A total of 200 batches of Gas Gain were mamufactured during the current production period. Energy Products determines its cost and chemical usage variations at the end of each production period. The quantities of chemicals purchased and used during the current production period are shown in the following schedule. A total of 200 batches of Gas Gain were manufactured during the current production period. Energy Products determines its cost and chemical usage variations at the end of each production period. Compute the total direct materials usage variance, and then break down this variance into its mix and yleld components. Do not round intermediate computations and round final answers to the nearest cent. (CMA adapted)