Answered step by step

Verified Expert Solution

Question

1 Approved Answer

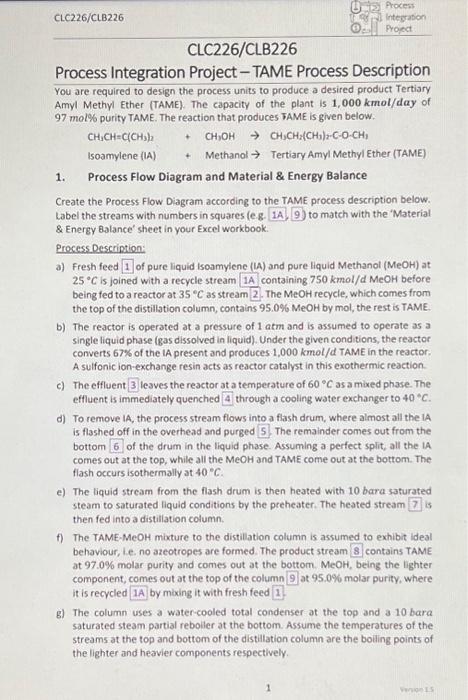

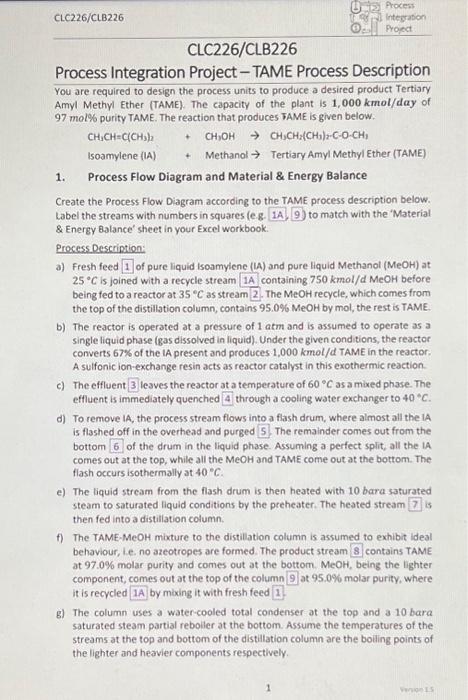

Draw the Process Flow Diagram of TAME plant Process CLC226/CLB226 Inteyation Project CLC226/CLB226 Process Integration Project - TAME Process Description You are required to design

Draw the Process Flow Diagram of TAME plant

Process CLC226/CLB226 Inteyation Project CLC226/CLB226 Process Integration Project - TAME Process Description You are required to design the process units to produce a desired product Tertiary Amyl Methyl Ether (TAME). The capacity of the plant is 1,000 kmol/daay of 97 mol\% purity TAME. The reaction that produces JAME is given below. Isoamylene(IA)+MethanolTertiaryAmylMethylEther(TAME) 1. Process Flow Diagram and Material 8 Energy Balance Create the Process Flow Diagram according to the TAME process description below. Label the streams with numbers in squares ( e.g. 1A, 9) to match with the 'Material \& Energy Balance' sheet in your Excel workbook. Process Description: a) Fresh feed 1 of pure liquid isoamylene (IA) and pure liquid Methanol (MeOH) at 25C is joined with a recycle stream 1A containing 750kmol/dMeOH before being fed to a reactor at 35C as stream 2. The MeOH recycle, which comes from the top of the distiliation column, contains 95.0%MeOH by mol, the rest is TAME. b) The reactor is operated at a pressure of 1 atm and is assumed to operate as a single liquid phase (gas dissolved in liquid). Under the given conditions, the reactor converts 67% of the LA present and produces 1,000kmol/d TAME in the reactor: A sulfonic ion-exchange resin acts as reactor catalyst in this exothermic reaction. c) The effluent leaves the reactor at a temperature of 60C as a mixed phase. The effluent is immediately quenched (4 through a cooling water exchanger to 40C. d) To remove IA, the process stream flows into a flash drum, where almost all the IA is flashed off in the overhead and purged 5. The remainder comes out from the bottom of the drum in the liquid phase. Assuming a perfect split, all the IA comes out at the top, while all the MeOH and TAME come out at the bottom. The flash occurs isothermally at 40C. e) The liquid stream from the flash drum is then heated with 10 bara saturated steam to saturated liquid conditions by the preheater. The heated stream then fed into a distiliation column. f) The TAME-MeOH mixture to the distillation column is assumed to exhibit ideal behaviour, l.e. no azeotropes are formed. The product stream 8 contains TAME at 97.0% molar purity and comes out at the bottom. MeOH, being the lighter component, comes out at the top of the column 9 at 95.0% molar purity, where it is recycled 1A by mbing it with fresh feed 1. g) The column uses a water-cooled total condenser at the top and a 10 bara saturated steam partial rebolier at the bottom. Assume the temperatures of the streams at the top and bottom of the distillation column are the boling points of the lighter and heavier components respectively. 1

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started