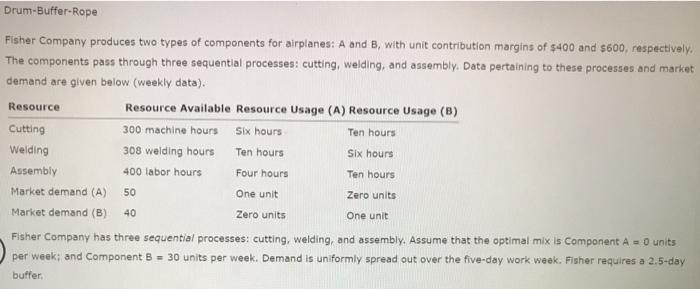

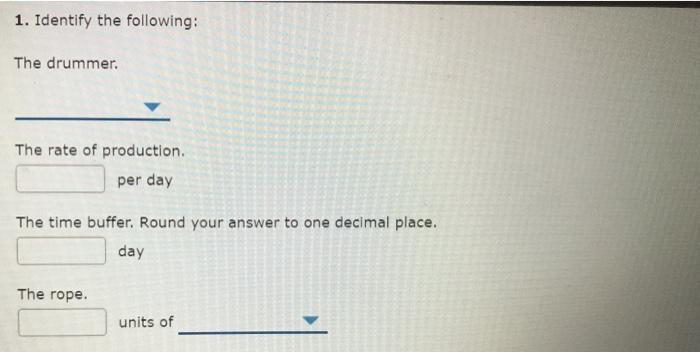

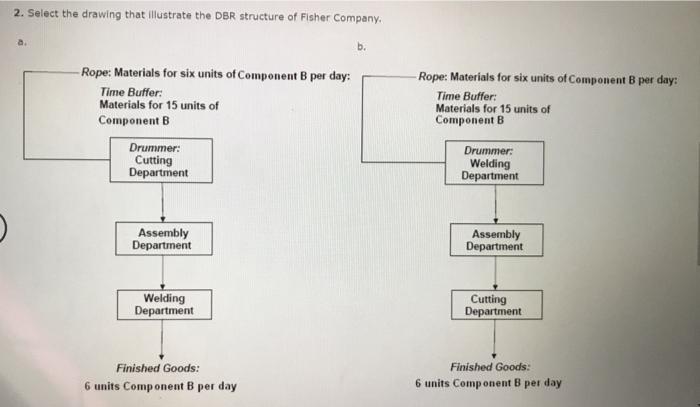

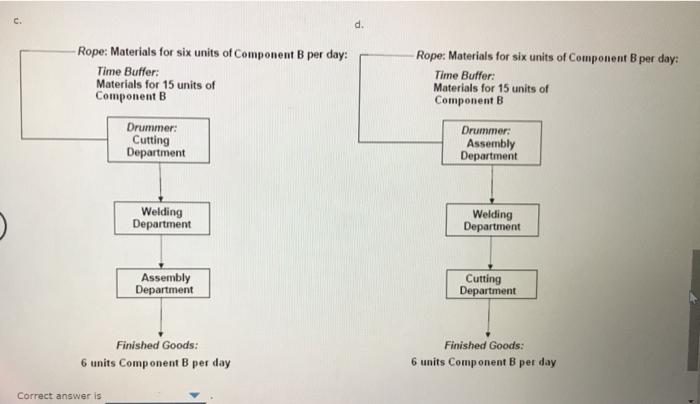

Drum-Buffer-Rope Fisher Company produces two types of components for airplanes: A and B, with unit contribution margins of $400 and $600, respectively. The components pass through three sequential processes: cutting, welding, and assembly. Data pertaining to these processes and market demand are given below (weekly data). Resource Resource Available Resource Usage (A) Resource Usage (B) Cutting 300 machine hours Ten hours Welding 308 welding hours Ten hours Six hours Assembly 400 labor hours Ten hours Market demand (A) 50 Market demand (B) 40 Zero units One unit Six hours Four hours One unit Zero units Fisher Company has three sequential processes: cutting, welding, and assembly. Assume that the optimal mix is Component A = 0 units per week; and Component B = 30 units per week. Demand is uniformly spread out over the five-day work week. Fisher requires a 2.5-day buffer, 1. Identify the following: The drummer. The rate of production. per day The time buffer. Round your answer to one decimal place. day The rope. units of 2. Select the drawing that illustrate the DBR structure of Fisher Company, b. Rope: Materials for six units of Component B per day: Time Buffer: Materials for 15 units of Component B Drummer: Cutting Department Rope: Materials for six units of Component B per day: Time Buffer: Materials for 15 units of Component B Drummer: Welding Department Assembly Department Assembly Department Welding Department Cutting Department Finished Goods: 6 units Component B per day Finished Goods: 6 units Component B per day C. d. Rope: Materials for six units of Component B per day: Time Buffer: Materials for 15 units of Component B Rope: Materials for six units of Component B per day: Time Buffer: Materials for 15 units of Component B Drummer: Cutting Department Drummer: Assembly Department Welding Department Welding Department Assembly Department Cutting Department Finished Goods: 6 units Component B per day Finished Goods: 6 units Component B per day Correct answer is 3. What if the Welding Department was allowed or encouraged to produce at capacity? What effect will this have on work-in-process Inventories