Question

Excellence Manufacturing Sdn Bhd is a plastic injection molding company that producing household plastic products. Steve, the Operation and Quality Director of the company plans

Excellence Manufacturing Sdn Bhd is a plastic injection molding company that producing household plastic products. Steve, the Operation and Quality Director of the company plans to implement few quality control and improvement initiatives such as sampling inspection and statistical process control (SPC) at varies stage of the production line. You have been asked to give the advice of the following.

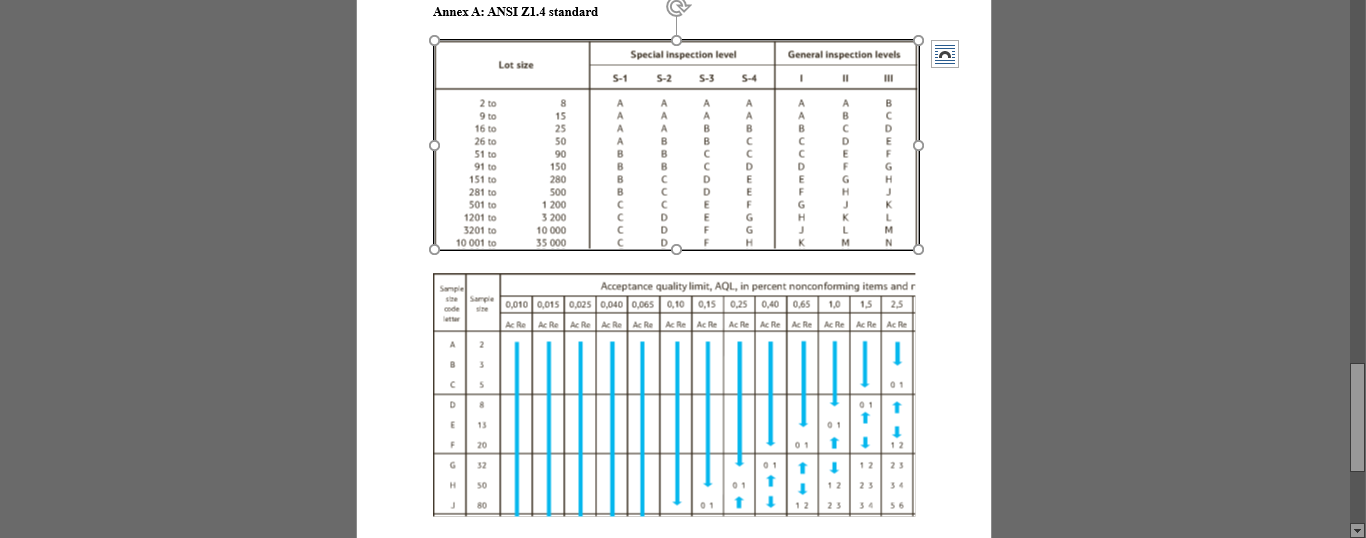

- Steve intends to start sampling inspection on the plastic parts produced by the injection molding machine. The plastic parts are produced in the batch of 250. Propose a single sampling inspection plan for the company bases on ANSI Z1.4 standard. Assumed that the company willing to accept Type 1 error of 0.025.

- The result of sampling inspection is not encouraging. 3 out of the 5 lots are rejected. As such, Steve would like to investigate the cause of failure by using Quality 7 tools. Explain to Steve the 7 quality tools that possibility he could applied and the objective of each tool.

- To assess the stability of injection molding process, a sub group sample of 6 plastic parts are collected each day and length of the plastic parts are measured. Data collected for a period of 20 days is summarized in the Table 1.0

| Table 1.0 Plastic Part Dimension (in mm)

|

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started