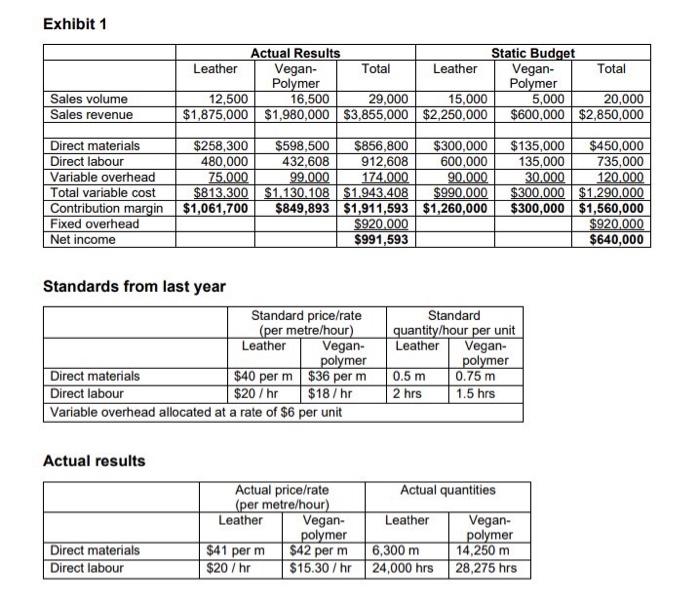

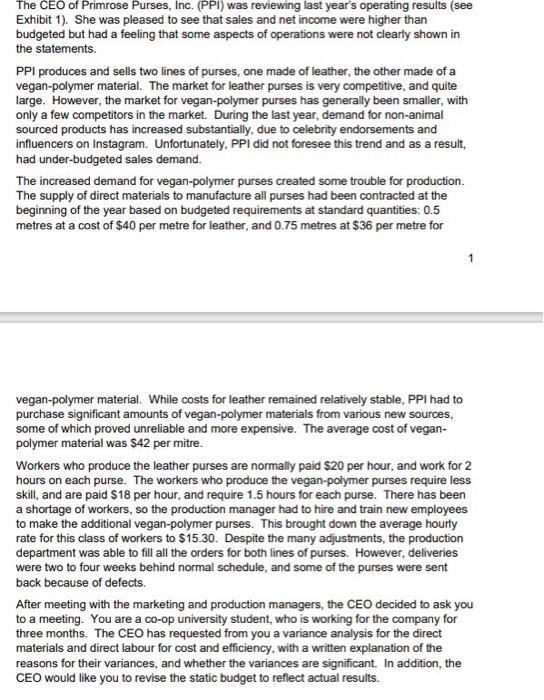

Exhibit 1 Actual Results Static Budget Leather Vegan- Total Leather Vegan- Total Polymer Polymer 12,500 16,500 29,000 15,000 5,000 20,000 $1,875,000 $1,980,000 $3,855,000 $2,250,000 $600,000 $2,850,000 Sales volume Sales revenue Direct materials $258,300 $598,500 $856,800 $300,000 Direct labour 480,000 432,608 912,608 600,000 Variable overhead 75.000 99.000 174.000 90.000 Total variable cost $813.300 $1.130.108 $1.943.408 $990.000 Contribution margin $1,061,700 $849,893 $1,911,593 $1,260,000 Fixed overhead $920.000 Net income $991,593 $135,000 $450,000 135,000 735,000 30.000 120.000 $300,000 $1.290.000 $300,000 $1,560,000 $920,000 $640,000 Standards from last year Standard price/rate (per metre/hour) Leather Vegan- polymer Direct materials $40 per m $36 per m Direct labour $20/hr $18/hr Variable overhead allocated at a rate of $6 per unit Standard quantity/hour per unit Leather Vegan- polymer 0.5 m 0.75 m 2 hrs 1.5 hrs Actual results Actual quantities Leather Actual price/rate (per metre/hour) Leather Vegan- polymer $41 per m $42 per m $20 /hr $15.30/hr Direct materials Direct labour 6,300 m 24,000 hrs Vegan- polymer 14,250 m 28,275 hrs The CEO of Primrose Purses, Inc. (PPI) was reviewing last year's operating results (see Exhibit 1). She was pleased to see that sales and net income were higher than budgeted but had a feeling that some aspects of operations were not clearly shown in the statements. PPI produces and sells two lines of purses, one made of leather, the other made of a vegan-polymer material. The market for leather purses is very competitive, and quite large. However, the market for vegan-polymer purses has generally been smaller, with only a few competitors in the market. During the last year, demand for non-animal sourced products has increased substantially, due to celebrity endorsements and influencers on Instagram. Unfortunately, PPI did not foresee this trend and as a result, had under-budgeted sales demand. The increased demand for vegan-polymer purses created some trouble for production. The supply of direct materials to manufacture all purses had been contracted at the beginning of the year based on budgeted requirements at standard quantities: 0.5 metres at a cost of $40 per metre for leather, and 0.75 metres at $36 per metre for vegan-polymer material. While costs for leather remained relatively stable, PPI had to purchase significant amounts of vegan-polymer materials from various new sources, some of which proved unreliable and more expensive. The average cost of vegan- polymer material was $42 per mitre. Workers who produce the leather purses are normally paid $20 per hour, and work for 2 hours on each purse. The workers who produce the vegan-polymer purses require less skill, and are paid $18 per hour, and require 1.5 hours for each purse. There has been a shortage of workers, so the production manager had to hire and train new employees to make the additional vegan-polymer purses. This brought down the average hourly rate for this class of workers to $15.30. Despite the many adjustments, the production department was able to fill all the orders for both lines of purses. However, deliveries were two to four weeks behind normal schedule, and some of the purses were sent back because of defects After meeting with the marketing and production managers, the CEO decided to ask you to a meeting. You are a co-op university student who is working for the company for three months. The CEO has requested from you a variance analysis for the direct materials and direct labour for cost and efficiency, with a written explanation of the reasons for their variances, and whether the variances are significant. In addition, the CEO would like you to revise the static budget to reflect actual results