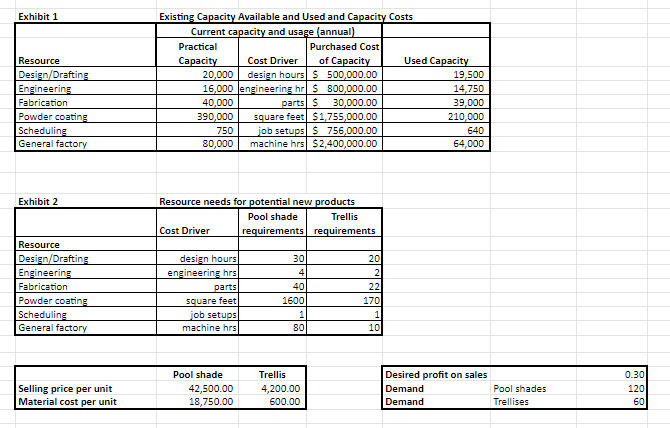

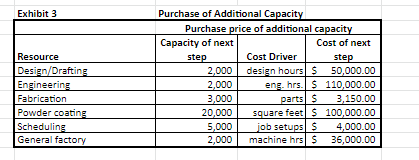

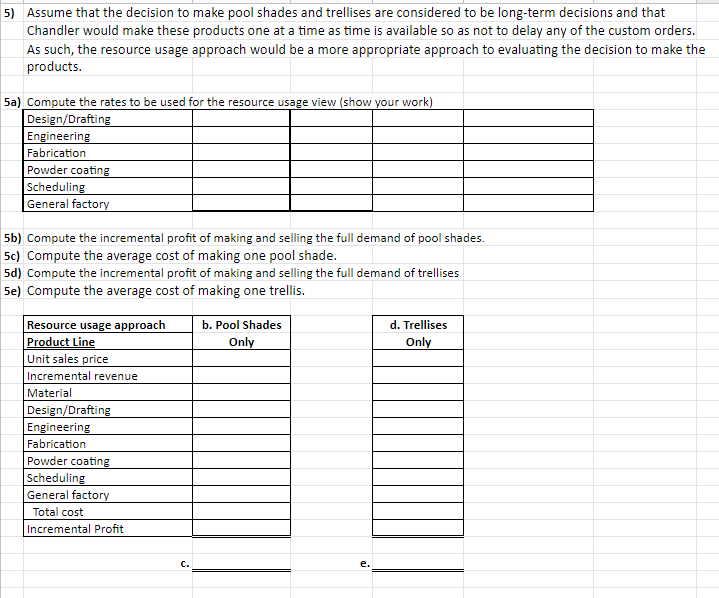

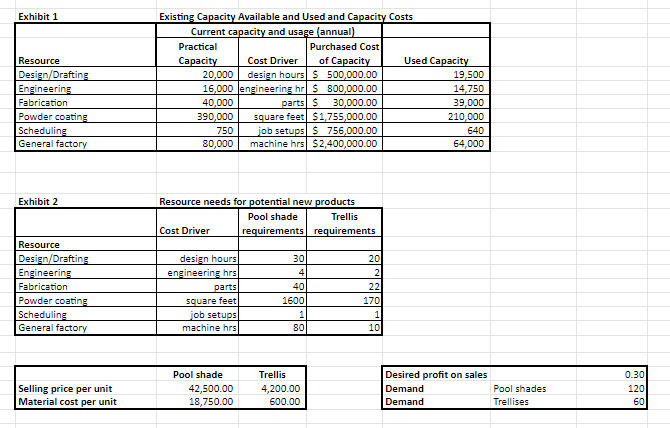

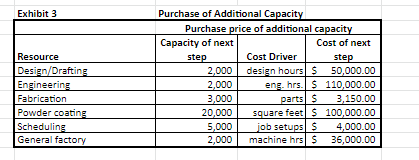

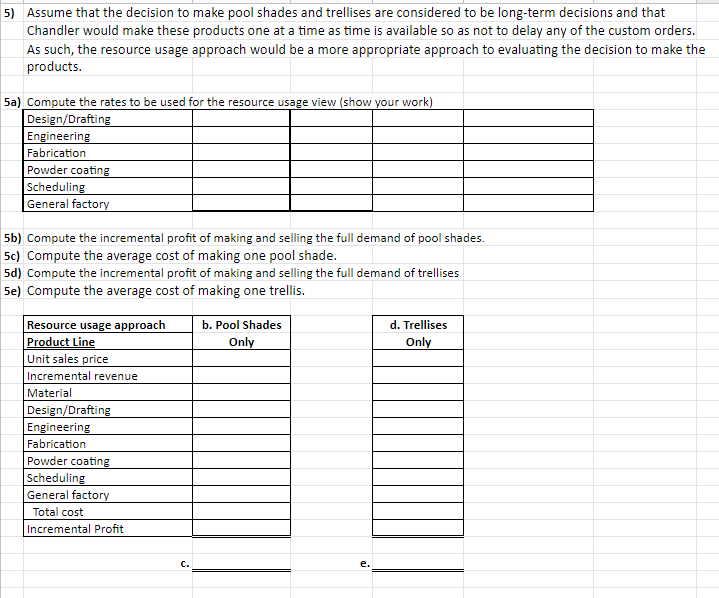

Exhibit 1 Existing Capacity Available and Used and Capacity Costs \begin{tabular}{|l|r|r|r|r|} \hline & \multicolumn{2}{|c|}{ Current capacity and usage (annual) } & \\ \cline { 2 - 5 } & Practical Capacity & Cost Driver & Purchased Cost of Capacity & Used Capacity \\ \hline Resource & 20,000 & design hours & $500,000.00 & 19,500 \\ \hline Design/Drafting & 16,000 & engineering hr & $800,000.00 & 14,750 \\ \hline Engineering & 40,000 & parts & $30,000.00 & 39,000 \\ \hline Fabrication & 390,000 & square feet & $1,755,000.00 & 210,000 \\ \hline Powder coating & 750 & job setups & $756,000.00 & 640 \\ \hline Scheduling & 80,000 & machine hrs & $2,400,000.00 & 64,000 \\ \hline General factory & \end{tabular} Exhibit 2 Resource needs for potential new products \begin{tabular}{|l|r|r|r|} \hline & \multicolumn{1}{|c|}{ Cost Driver } & Pool shade requirements & Trellis requirements \\ \hline Resource & & & \\ \hline Design/Drafting & design hours & 30 & 20 \\ \hline Engineering & engineering hrs & 4 & 22 \\ \hline Fabrication & parts & 40 & 22 \\ \hline Powder coating & square feet & 1600 & 170 \\ \hline Scheduling & job setups & 1 & 1 \\ \hline General factory & machine hrs & 80 & 10 \\ \hline \end{tabular} \begin{tabular}{|l|r|r|} \hline & \multicolumn{1}{|c|}{ Pool shade } & \multicolumn{1}{c|}{ Trellis } \\ \hline Selling price per unit & 42,500.00 & 4,200.00 \\ \hline Material cost per unit & 18,750.00 & 600.00 \\ \hline \end{tabular} Exhibit 3 Purchase of Additional Capacity Assume that the decision to make pool shades and trellises are considered to be long-term decisions and that Chandler would make these products one at a time as time is available so as not to delay any of the custom orders. As such, the resource usage approach would be a more appropriate approach to evaluating the decision to make the products. a) Comnute the ratec th he uced fine the reenurre ucade view (ehnow ynur wark) b) Compute the incremental profit of making and selling the full demand of pool shades. c) Compute the average cost of making one pool shade. d) Compute the incremental profit of making and selling the full demand of trellises e) Compute the average cost of making one trellis. Exhibit 1 Existing Capacity Available and Used and Capacity Costs \begin{tabular}{|l|r|r|r|r|} \hline & \multicolumn{2}{|c|}{ Current capacity and usage (annual) } & \\ \cline { 2 - 5 } & Practical Capacity & Cost Driver & Purchased Cost of Capacity & Used Capacity \\ \hline Resource & 20,000 & design hours & $500,000.00 & 19,500 \\ \hline Design/Drafting & 16,000 & engineering hr & $800,000.00 & 14,750 \\ \hline Engineering & 40,000 & parts & $30,000.00 & 39,000 \\ \hline Fabrication & 390,000 & square feet & $1,755,000.00 & 210,000 \\ \hline Powder coating & 750 & job setups & $756,000.00 & 640 \\ \hline Scheduling & 80,000 & machine hrs & $2,400,000.00 & 64,000 \\ \hline General factory & \end{tabular} Exhibit 2 Resource needs for potential new products \begin{tabular}{|l|r|r|r|} \hline & \multicolumn{1}{|c|}{ Cost Driver } & Pool shade requirements & Trellis requirements \\ \hline Resource & & & \\ \hline Design/Drafting & design hours & 30 & 20 \\ \hline Engineering & engineering hrs & 4 & 22 \\ \hline Fabrication & parts & 40 & 22 \\ \hline Powder coating & square feet & 1600 & 170 \\ \hline Scheduling & job setups & 1 & 1 \\ \hline General factory & machine hrs & 80 & 10 \\ \hline \end{tabular} \begin{tabular}{|l|r|r|} \hline & \multicolumn{1}{|c|}{ Pool shade } & \multicolumn{1}{c|}{ Trellis } \\ \hline Selling price per unit & 42,500.00 & 4,200.00 \\ \hline Material cost per unit & 18,750.00 & 600.00 \\ \hline \end{tabular} Exhibit 3 Purchase of Additional Capacity Assume that the decision to make pool shades and trellises are considered to be long-term decisions and that Chandler would make these products one at a time as time is available so as not to delay any of the custom orders. As such, the resource usage approach would be a more appropriate approach to evaluating the decision to make the products. a) Comnute the ratec th he uced fine the reenurre ucade view (ehnow ynur wark) b) Compute the incremental profit of making and selling the full demand of pool shades. c) Compute the average cost of making one pool shade. d) Compute the incremental profit of making and selling the full demand of trellises e) Compute the average cost of making one trellis