Expert Q&A

hello please work out homework for me , please

number each question and write clear as possible

using BEARD MARIANNA J Numbers.

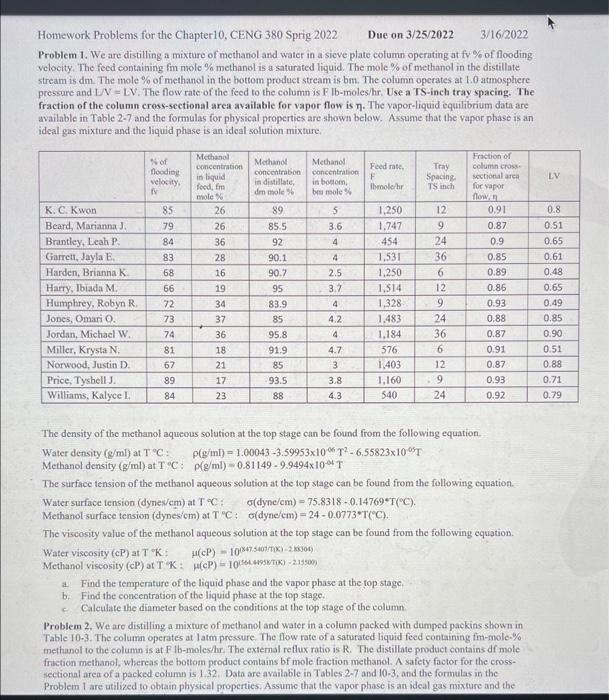

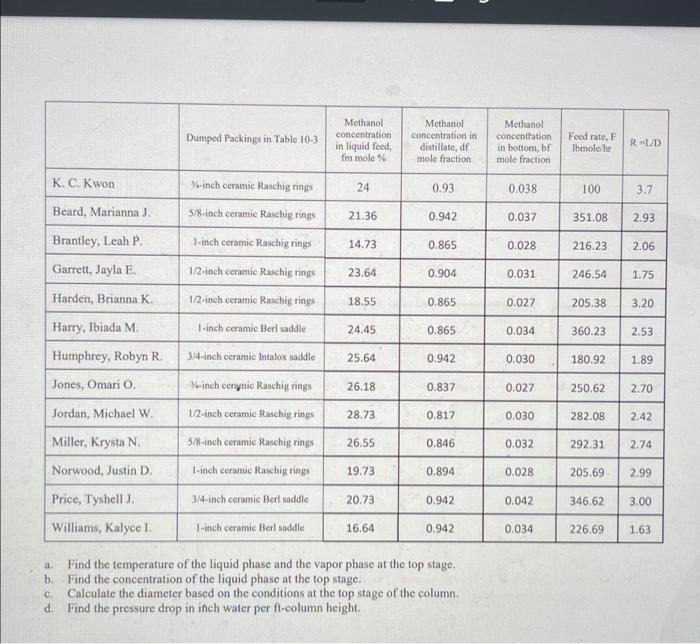

Homework Problems for the Chapter10, CENG 380 Sprig 2022 Due on 3/25/2022 3/16/2022 Problem 1. We are distilling a mixture of methanol and water in a sieve plate column operating at fv % of flooding vclocity. The feed containing fm mole % methanol is a saturated liquid. The mole% of methanol in the distillate stream is dm. The mole% of methanol in the bottom product stream is bm. The column operates at 1.0 atmosphere pressure and L/V = LV. The flow rate of the feed to the column is Fib-moles/hr. Use a TS-inch tray spacing. The fraction of the column cross-sectional area available for vapor flow is 71. The vapor-liquid equilibrium data are available in Table 2-7 and the formulas for physical properties are shown below. Assume that the vapor phase is an ideal gas mixture and the liquid phase is an ideal solution mixture. Wor Dooding velocity PV Methanol concentration in bottom be mole Feed rate F Imolar Tray Spacing TS inch Fraction of column cross sectional area LV fue por flow Methanol concentration in liquid food, fm mole 26 26 36 28 16 5 3.6 4 4 2.5 3.7 Methanol concentration in distillate dm mole 89 85.5 92 90.1 90.7 95 83.9 85 95.8 91.9 85 93.5 88 0.8 0.51 0.65 0.61 0.48 0.65 K.C. Kwon Beard, Marianna J. Brantley. Leah P Garrett, Jayla E Harden, Brianna K Harry, Ibiada M. Humphrey, Robyn R Jones, Omari O. Jordan, Michael W. Miller, Krysta N. Norwood, Justin D. Price, Tyshell J. Williams, Kalyce 19 85 79 84 83 68 66 72 73 74 81 67 89 84 34 37 36 18 21 17 23 1.250 1.747 454 1.531 1.250 1.514 1,328 1.483 1.184 576 1.403 1,160 540 4 4.2 4 4.7 3 3.8 4.3 12 9 24 36 6 12 9 24 36 6 12 9 24 0.49 0.91 0.87 0.9 0.85 0.89 0.86 0.93 0.88 0.87 0.91 0.87 0.93 0.92 0.85 0.90 0.51 0.88 0.71 0.79 The density of the methanol aqueous solution at the top stage can be found from the following equation Water density (W/ml) at TC: p(g/ml) - 1.00043 -3.59953x10T-6.55823x100T Methanol density (g/ml) at TC: plg/ml) - 0.81149 -9.9494x10-04T The surface tension of the methanol aqueous solution at the top stage can be found from the following equation Water surface tension (dynes/em) at TC: odyne/cm) - 75.8318.0.14769*T("C). Methanol surface tension (dynes/cm) at T "C: odyne/cm) - 24 -0.0773*T(C). The viscosity value of the methanol aqueous solution at the top stage can be found from the following equation. Water viscosity (CP) at TK (CP) - 10/7.540TK) 25300) Methanol viscosity (CP) at TK: HP) - 106.49SVTOR)-2.19500) 4. Find the temperature of the liquid phase and the vapor phase at the top stage, b. Find the concentration of the liquid phase at the top stage. Calculate the diameter based on the conditions at the top stage of the column. Problem 2. We are distilling a mixture of methanol and water in a column packed with dumped packins shown in Table 10-3. The column operates at lat pressure. The flow rate of a saturated liquid feed containing tim-mole.% methanol to the column is at Fib-moles/hr. The external reflux ratio is R. The distillate product contains df mole fraction methanol, whereas the bottom product contains bf mole fraction methanol. A safety factor for the cross- sectional area of a packed column is 132 Data are available in Tables 2-7 and 10-3, and the formulas in the Problem I are utilized to obtain physical properties. Assume that the vapor phase is an ideal gas mixture and the c Dumped Packings in Table 10-3 Methanol concentration in liquid feed Im mole Methanol concentration in distillate, dr mole fraction Methanol concentration in bottom, bf mole fraction Feed rate, F Ibmole/hr RUD KC Kwon %-inch ceramic Raschig rings 24 0.93 0.038 100 3.7 Beard, Marianna J. 5/8-inch ceramic Raschig rings 21.36 0.942 0.037 351.08 2.93 Brantley, Leah P. 1-inch ceramic Raschig rings 14.73 0.865 0.028 216.23 2.06 112-inch ceramic Raschig rings 23.64 0.904 0.031 246.54 1.75 Garrett, Jayla E Harden, Brianna K 1/2-inch ceramic Raschig rings 18.55 0.865 0.027 205.38 3.20 Harry, Ibiada M 1-inch ceramic Berl saddle 24.45 0.865 0.034 360.23 2.53 Humphrey, Robyn R 3/4-inch ceramic Intalox saddle 25.64 0.942 0.030 180.92 1.89 Jones, Omari O. 26.18 0.837 0.027 250.62 2.70 Princh cenynic Raschig rings 1/2-inch ceramic Raschig rings Jordan, Michael W. 28.73 0.817 0.030 282.08 2.42 Miller, Krysta N. 5/8-inch ceramic Raschig rings 26.55 0.846 0.032 292.31 2.74 Norwood, Justin D 1-inch ceramie Raschig rings 19.73 0.894 0.028 205.69 2.99 Price, Tyshell 3/4-inch ceramic Berl saddle 20.73 0.942 0.042 346.62 3.00 Williams, Kalyce 1 1-inch ceramic Berl saddle 16.64 0.942 0.034 226.69 1.63 a. b. C. d. Find the temperature of the liquid phase and the vapor phase at the top stage. Find the concentration of the liquid phase at the top stage. Calculate the diameter based on the conditions at the top stage of the column. Find the pressure drop in inch water per ft-column height