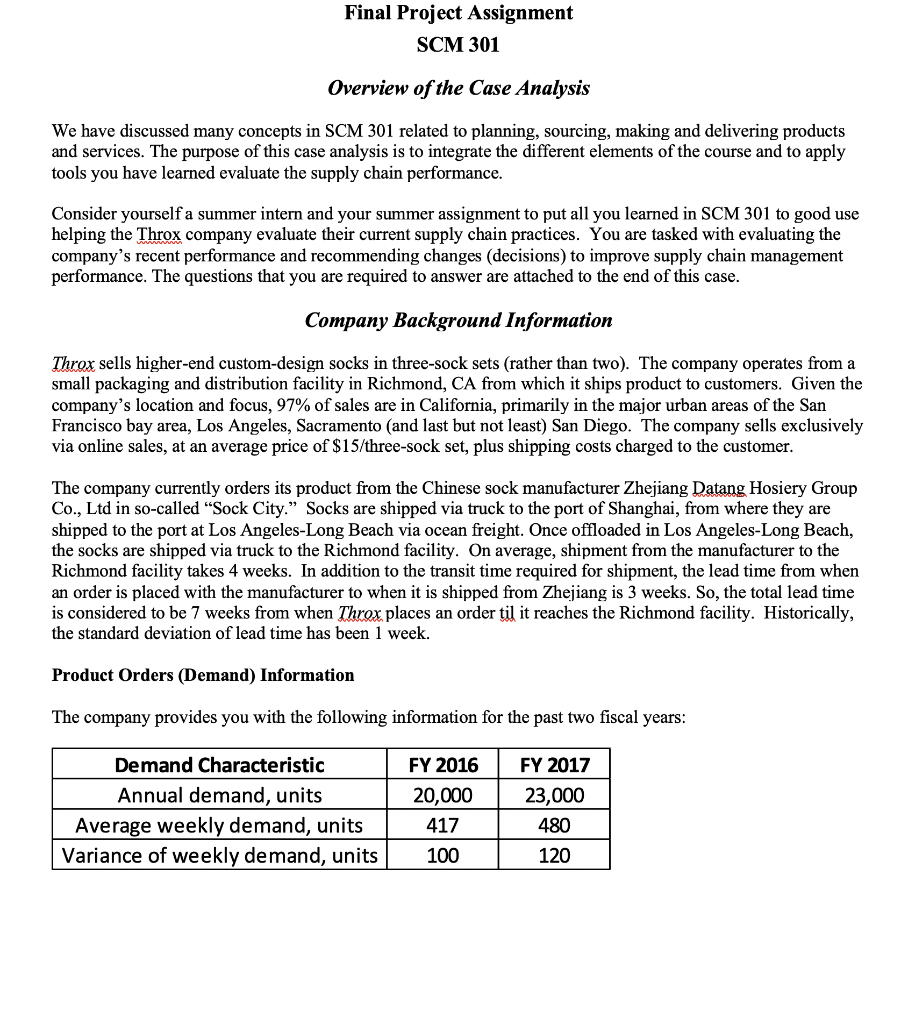

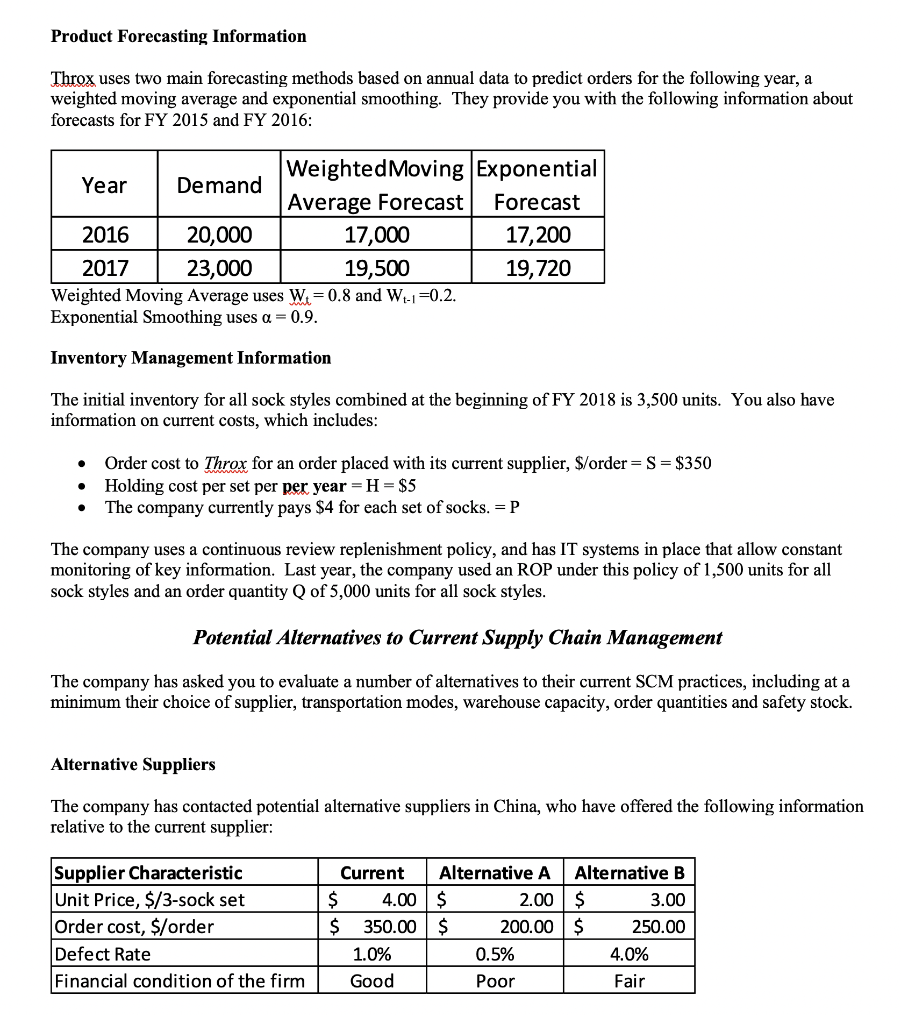

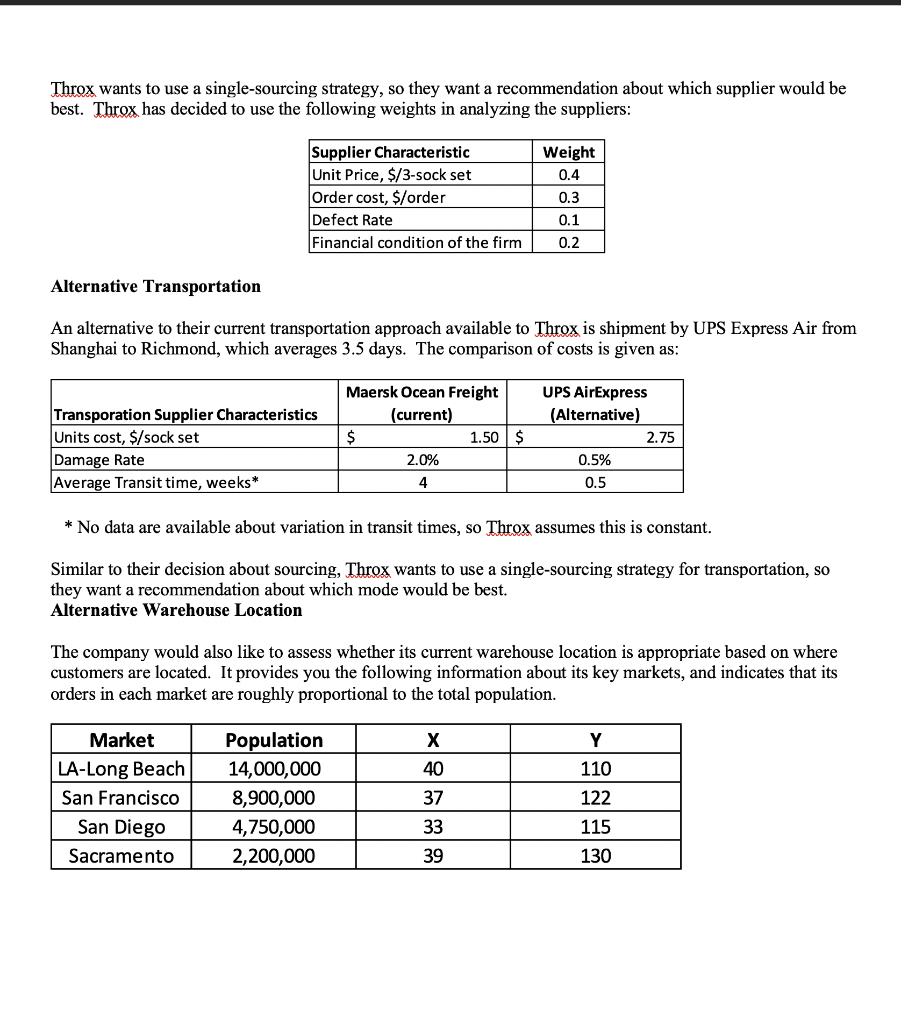

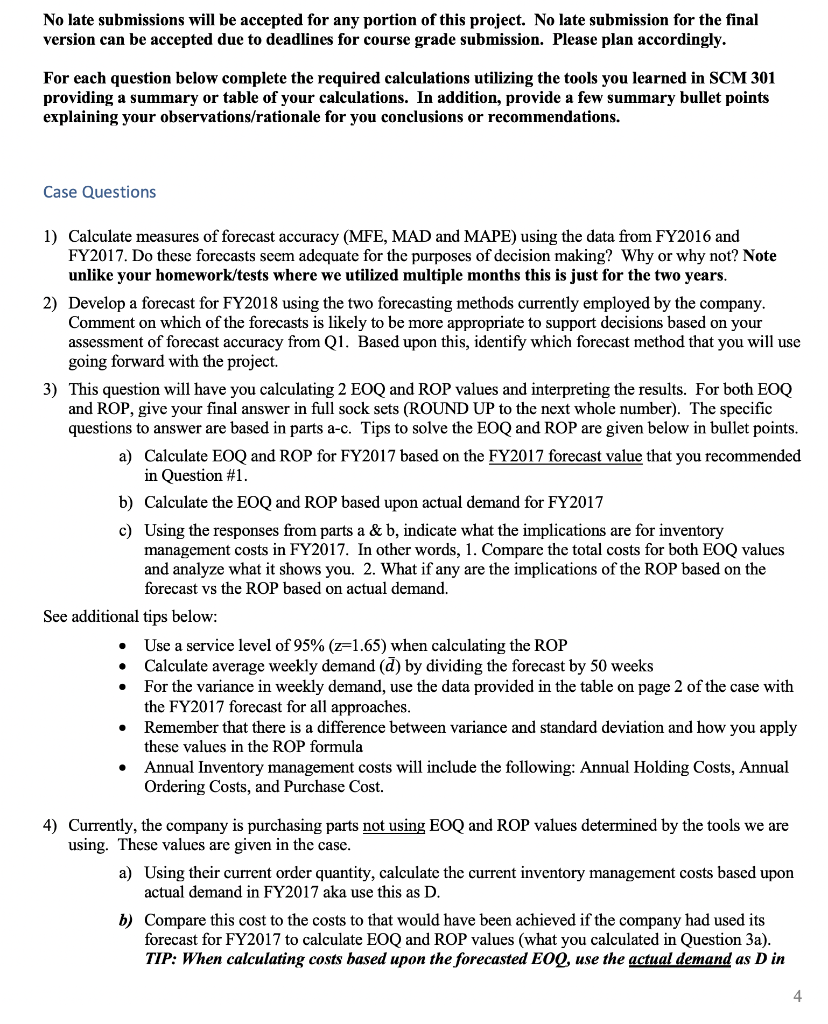

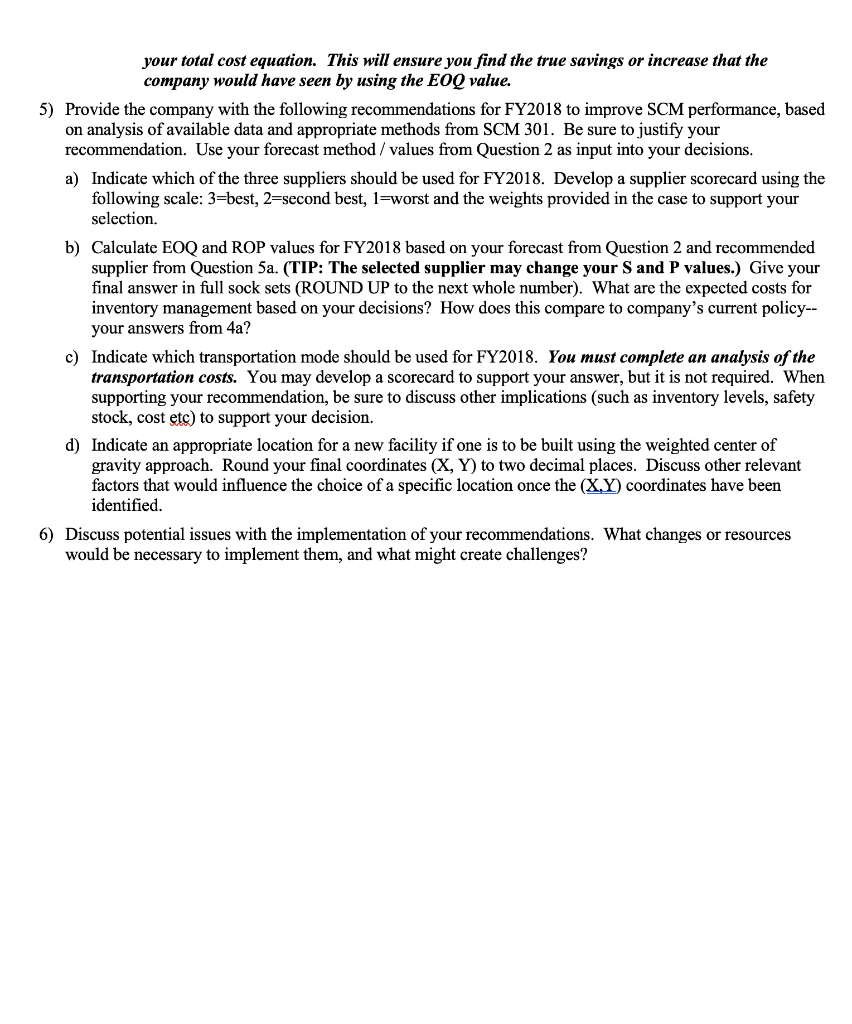

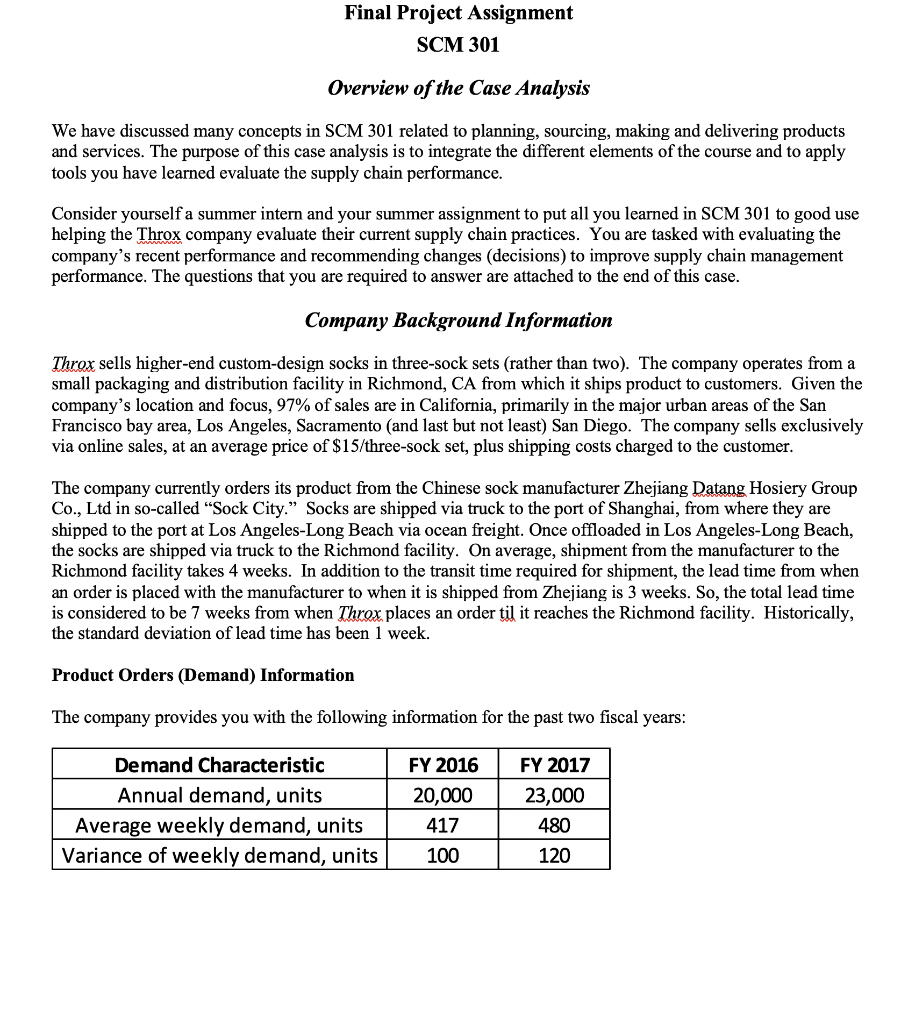

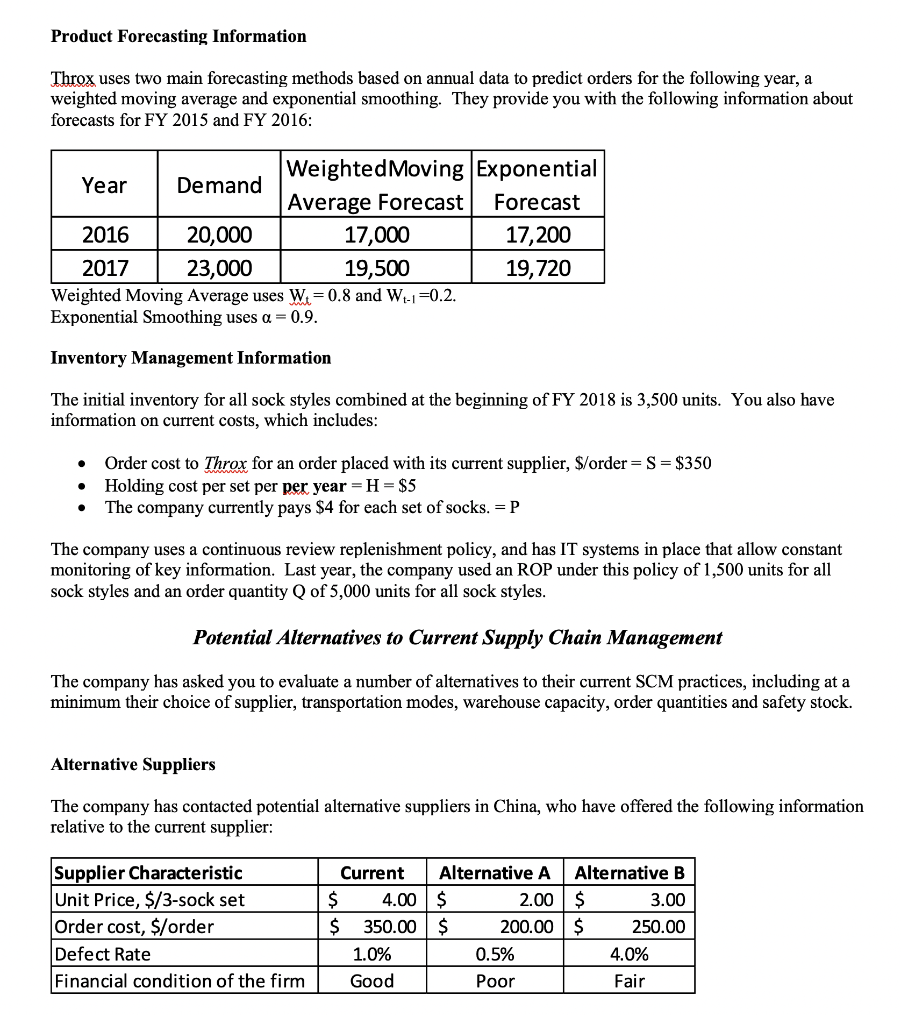

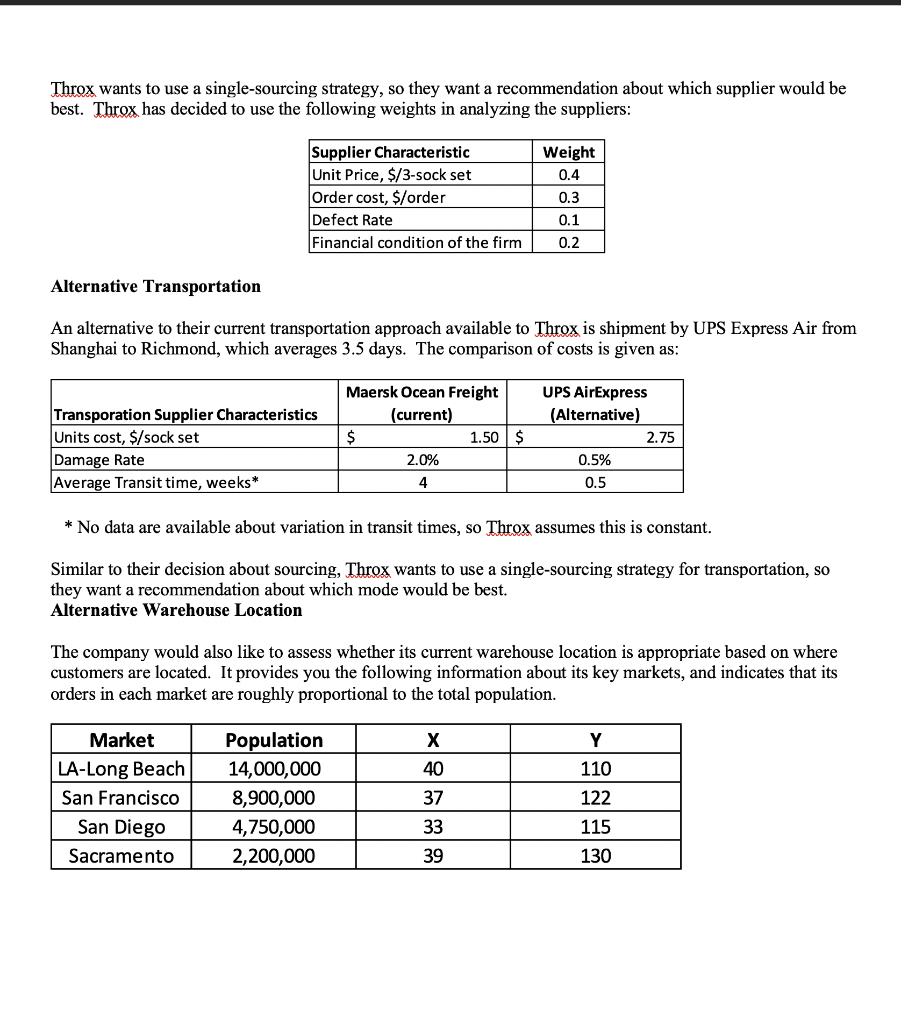

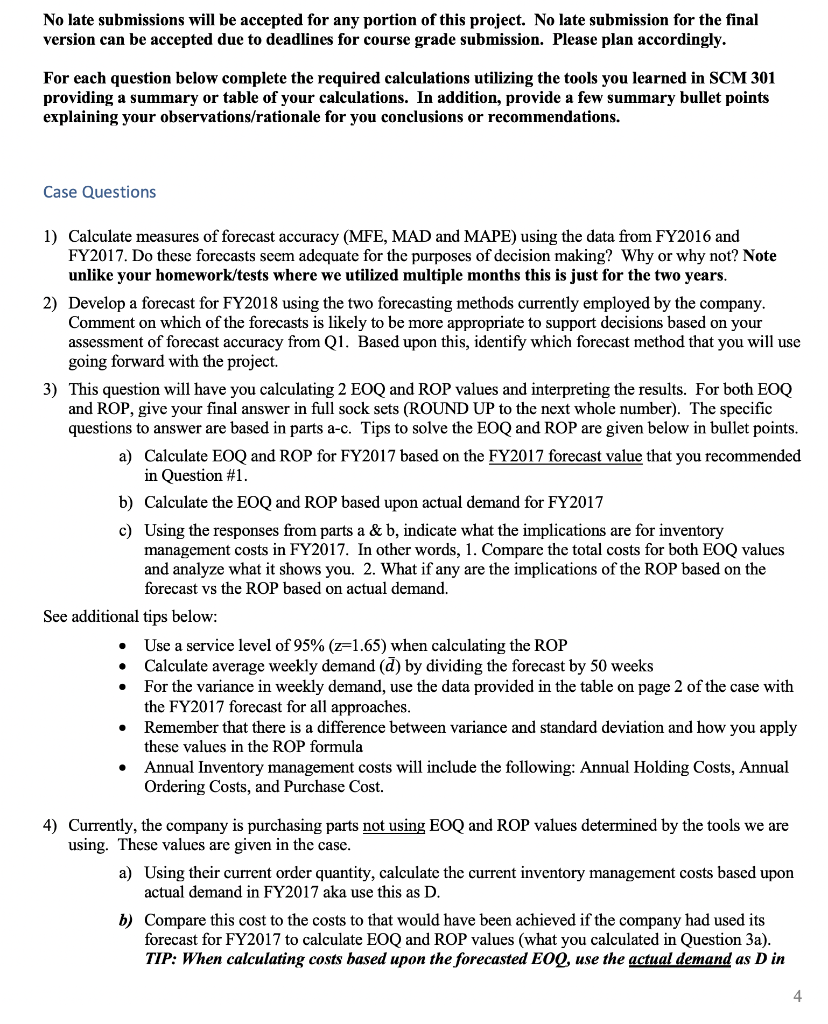

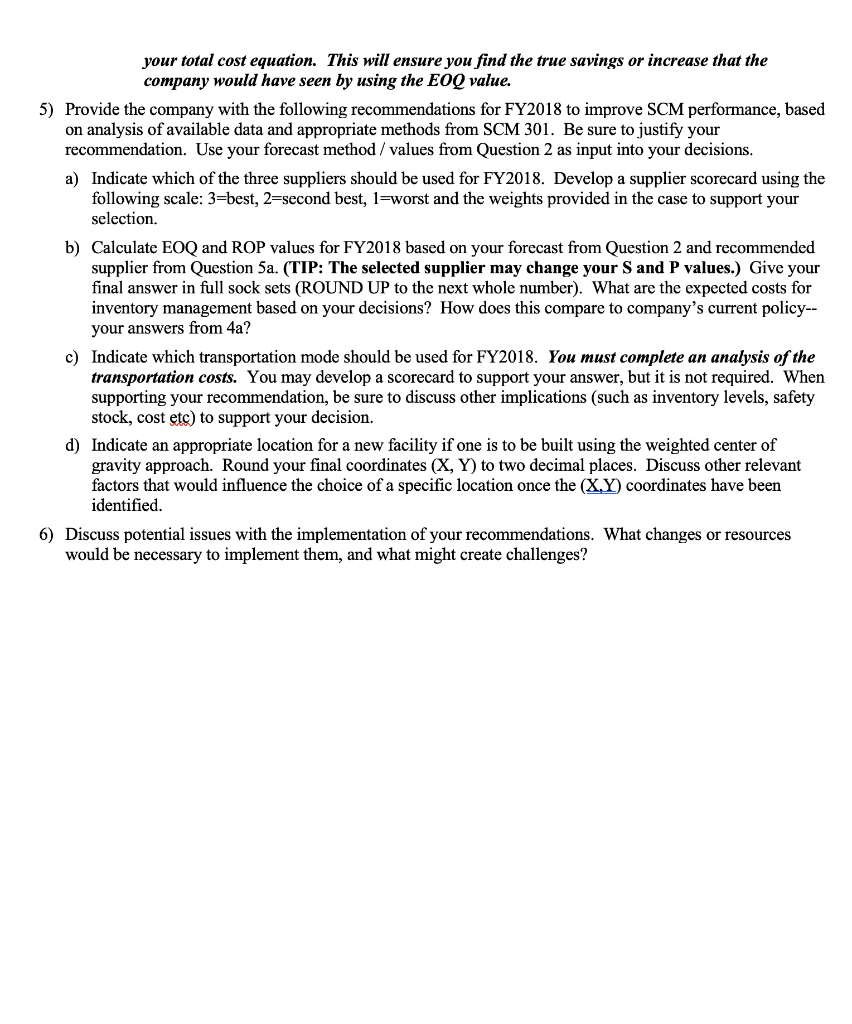

Final Project Assignment SCM 301 Overview of the Case Analysis We have discussed many concepts in SCM 301 related to planning, sourcing, making and delivering products and services. The purpose of this case analysis is to integrate the different elements of the course and to apply tools you have learned evaluate the supply chain performance. Consider yourself a summer intern and your summer assignment to put all you learned in SCM 301 to good use helping the Throx company evaluate their current supply chain practices. You are tasked with evaluating the company's recent performance and recommending changes (decisions) to improve supply chain management performance. The questions that you are required to answer are attached to the end of this case. Company Background Information Throx sells higher-end custom-design socks in three-sock sets (rather than two). The company operates from a small packaging and distribution facility in Richmond, CA from which it ships product to customers. Given the company's location and focus, 97% of sales are in California, primarily in the major urban areas of the San Francisco bay area, Los Angeles, Sacramento (and last but not least) San Diego. The company sells exclusively via online sales, at an average price of $15/three-sock set, plus shipping costs charged to the customer. The company currently orders its product from the Chinese sock manufacturer Zhejiang Datang Hosiery Group Co., Ltd in so-called Sock City. Socks are shipped via truck to the port of Shanghai, from where they are shipped to the port at Los Angeles-Long Beach via ocean freight. Once offloaded in Los Angeles-Long Beach, the socks are shipped via truck to the Richmond facility. On average, shipment from the manufacturer to the Richmond facility takes 4 weeks. In addition to the transit time required for shipment, the lead time from when an order is placed with the manufacturer to when it is shipped from Zhejiang is 3 weeks. So, the total lead time is considered to be 7 weeks from when Throx places an order til it reaches the Richmond facility. Historically, the standard deviation of lead time has been 1 week. Product Orders (Demand) Information The company provides you with the following information for the past two fiscal years: Demand Characteristic Annual demand, units Average weekly demand, units Variance of weekly demand, units FY 2016 20,000 417 100 FY 2017 23,000 480 120 Product Forecasting Information Throx uses two main forecasting methods based on annual data to predict orders for the following year, a weighted moving average and exponential smoothing. They provide you with the following information about forecasts for FY 2015 and FY 2016: Weighted Moving Exponential Year Demand Average Forecast Forecast 2016 20,000 17,000 17,200 2017 23,000 19,500 19,720 Weighted Moving Average uses Wu=0.8 and W1-1=0.2. Exponential Smoothing uses a=0.9. Inventory Management Information The initial inventory for all sock styles combined at the beginning of FY 2018 is 3,500 units. You also have information on current costs, which includes: . Order cost to Throx for an order placed with current supplier, S/order=S=$350 Holding cost per set per per year = H = $5 The company currently pays $4 for each set of socks. =P . The company uses a continuous review replenishment policy, and has IT systems in place that allow constant monitoring of key information. Last year, the company used an ROP under this policy of 1,500 units for all sock styles and an order quantity Q of 5,000 units for all sock styles. Potential Alternatives to Current Supply Chain Management The company has asked you to evaluate a number of alternatives to their current SCM practices, including at a minimum their choice of supplier, transportation modes, warehouse capacity, order quantities and safety stock. Alternative Suppliers The company has contacted potential alternative suppliers in China, who have offered the following information relative to the current supplier: Supp Characteristic Unit Price, $/3-sock set Order cost, $/order Defect Rate Financial condition of the firm Current Alternative A $ 4.00 $ 2.00 $ 350.00 $ 200.00 1.0% 0.5% Good Poor Alternative B $ 3.00 $ 250.00 4.0% Fair Throx wants to use a single-sourcing strategy, so they want a recommendation about which supplier would be best. Throx has decided to use the following weights in analyzing the suppliers: Supplier Characteristic Unit Price, $/3-sock set Order cost, $/order Defect Rate Financial condition of the firm Weight 0.4 0.3 0.1 0.2 Alternative Transportation An alternative to their current transportation approach available to Throx is shipment by UPS Express Air from Shanghai to Richmond, which averages 3.5 days. The comparison of costs is given as: Transporation Supplier Characteristics Units cost, $/sock set Damage Rate Average Transit time, weeks* Maersk Ocean Freight (current) $ 1.50 $ 2.0% UPS AirExpress (Alternative) 2.75 0.5% 0.5 4 * No data are available about variation in transit times, so Throx assumes this is constant. Similar to their decision about sourcing, Throx wants to use a single-sourcing strategy for transportation, so they want a recommendation about which mode would be best. Alternative Warehouse Location The company would also like to assess whether its current warehouse location is appropriate based on where customers are located. It provides you the following information about its key markets, and indicates that its orders in each market are roughly proportional to the total population. Y 40 110 Market LA-Long Beach San Francisco San Diego Sacramento Population 14,000,000 8,900,000 4,750,000 2,200,000 122 37 33 39 115 130 No late submissions will be accepted for any portion of this project. No late submission for the final version can be accepted due to deadlines for course grade submission. Please plan accordingly. For each question below complete the required calculations utilizing the tools you learned in SCM 301 providing a summary or table of your calculations. In addition, provide a few summary bullet points explaining your observations/rationale for you conclusions or recommendations. Case Questions 1) Calculate measures of forecast accuracy (MFE, MAD and MAPE) using the data from FY2016 and FY2017. Do these forecasts seem adequate for the purposes of decision making? Why or why not? Note unlike your homework/tests where we utilized multiple months this is just for the two years. 2) Develop a forecast for FY2018 using the two forecasting methods currently employed by the company. Comment on which of the forecasts is likely to be more appropriate to support decisions based on your assessment of forecast accuracy from Q1. Based upon this, identify which forecast method that you will use going forward with the project. 3) This question will have you calculating 2 EOQ and ROP values and interpreting the results. For both EOQ and ROP, give your final answer in full sock sets (ROUND UP to the next whole number). The specific questions to answer are based in parts a-c. Tips to solve the EOQ and ROP are given below in bullet points. a) Calculate EOQ and ROP for FY2017 based on the FY2017 forecast value that you recommended in Question #1. b) Calculate the EOQ and ROP based upon actual demand for FY2017 c) Using the responses from parts a & b, indicate what the implications are for inventory management costs in FY2017. In other words, 1. Compare the total costs for both EOQ values and analyze what it shows you. 2. What if any are the implications of the ROP based on the forecast vs the ROP based on actual demand. See additional tips below: Use a service level of 95% (z=1.65) when calculating the ROP Calculate average weekly demand (d) by dividing the forecast by 50 weeks For the variance in weekly demand, use the data provided in the table on page 2 of the case with the FY2017 forecast for all approaches. Remember that there is a difference between variance and standard deviation and how you apply these values in the ROP formula Annual Inventory management costs will include the following: Annual Holding Costs, Annual Ordering Costs, and Purchase Cost. . . . . . 4) Currently, the company is purchasing parts not using EOQ and ROP values determined by the tools we are using. These values are given in the case. a) Using their current order quantity, calculate the current inventory management costs based upo actual demand in FY2017 aka use this as D. b) Compare this cost to the costs to that would have been achieved if the company had used its forecast for FY2017 to calculate EOQ and ROP values (what you calculated in Question 3a). TIP: When calculating costs based upon the forecasted EOQ, use the actual demand as D in your total cost equation. This will ensure you find the true savings or increase that the company would have seen by using the EOQ value. 5) Provide the company with the following recommendations for FY2018 to improve SCM performance, based on analysis of available data and appropriate methods from SCM 301. Be sure to justify your recommendation. Use your forecast method / values from Question 2 as input into your decisions. a) Indicate which of the three suppliers should be used for FY2018. Develop a supplier scorecard using the following scale: 3=best, 2=second best, 1=worst and the weights provided in the case to support your selection. b) Calculate EOQ and ROP values for FY2018 based on your forecast from Question 2 and recommended supplier from Question 5a. (TIP: The selected supplier may change your S and P values.) Give your final answer in full sock sets (ROUND UP to the next whole number). What are the expected costs for inventory management based on your decisions? How does this compare to company's current policy-- your answers from 4a? c) Indicate which transportation mode should be used for FY2018. You must complete an analysis of the transportation costs. You may develop a scorecard to support your answer, but it is not required. When supporting your recommendation, be sure to discuss other implications (such as inventory levels, safety stock, cost etc) to support your decision. d) Indicate an appropriate location for a new facility if one is to be built using the weighted center of gravity approach. Round your final coordinates (X, Y) to two decimal places. Discuss other relevant factors that would influence the choice of a specific location once the (X,Y) coordinates have been identified. 6) Discuss potential issues with the implementation of your recommendations. What changes or resources would be necessary to implement them, and what might create challenges? Final Project Assignment SCM 301 Overview of the Case Analysis We have discussed many concepts in SCM 301 related to planning, sourcing, making and delivering products and services. The purpose of this case analysis is to integrate the different elements of the course and to apply tools you have learned evaluate the supply chain performance. Consider yourself a summer intern and your summer assignment to put all you learned in SCM 301 to good use helping the Throx company evaluate their current supply chain practices. You are tasked with evaluating the company's recent performance and recommending changes (decisions) to improve supply chain management performance. The questions that you are required to answer are attached to the end of this case. Company Background Information Throx sells higher-end custom-design socks in three-sock sets (rather than two). The company operates from a small packaging and distribution facility in Richmond, CA from which it ships product to customers. Given the company's location and focus, 97% of sales are in California, primarily in the major urban areas of the San Francisco bay area, Los Angeles, Sacramento (and last but not least) San Diego. The company sells exclusively via online sales, at an average price of $15/three-sock set, plus shipping costs charged to the customer. The company currently orders its product from the Chinese sock manufacturer Zhejiang Datang Hosiery Group Co., Ltd in so-called Sock City. Socks are shipped via truck to the port of Shanghai, from where they are shipped to the port at Los Angeles-Long Beach via ocean freight. Once offloaded in Los Angeles-Long Beach, the socks are shipped via truck to the Richmond facility. On average, shipment from the manufacturer to the Richmond facility takes 4 weeks. In addition to the transit time required for shipment, the lead time from when an order is placed with the manufacturer to when it is shipped from Zhejiang is 3 weeks. So, the total lead time is considered to be 7 weeks from when Throx places an order til it reaches the Richmond facility. Historically, the standard deviation of lead time has been 1 week. Product Orders (Demand) Information The company provides you with the following information for the past two fiscal years: Demand Characteristic Annual demand, units Average weekly demand, units Variance of weekly demand, units FY 2016 20,000 417 100 FY 2017 23,000 480 120 Product Forecasting Information Throx uses two main forecasting methods based on annual data to predict orders for the following year, a weighted moving average and exponential smoothing. They provide you with the following information about forecasts for FY 2015 and FY 2016: Weighted Moving Exponential Year Demand Average Forecast Forecast 2016 20,000 17,000 17,200 2017 23,000 19,500 19,720 Weighted Moving Average uses Wu=0.8 and W1-1=0.2. Exponential Smoothing uses a=0.9. Inventory Management Information The initial inventory for all sock styles combined at the beginning of FY 2018 is 3,500 units. You also have information on current costs, which includes: . Order cost to Throx for an order placed with current supplier, S/order=S=$350 Holding cost per set per per year = H = $5 The company currently pays $4 for each set of socks. =P . The company uses a continuous review replenishment policy, and has IT systems in place that allow constant monitoring of key information. Last year, the company used an ROP under this policy of 1,500 units for all sock styles and an order quantity Q of 5,000 units for all sock styles. Potential Alternatives to Current Supply Chain Management The company has asked you to evaluate a number of alternatives to their current SCM practices, including at a minimum their choice of supplier, transportation modes, warehouse capacity, order quantities and safety stock. Alternative Suppliers The company has contacted potential alternative suppliers in China, who have offered the following information relative to the current supplier: Supp Characteristic Unit Price, $/3-sock set Order cost, $/order Defect Rate Financial condition of the firm Current Alternative A $ 4.00 $ 2.00 $ 350.00 $ 200.00 1.0% 0.5% Good Poor Alternative B $ 3.00 $ 250.00 4.0% Fair Throx wants to use a single-sourcing strategy, so they want a recommendation about which supplier would be best. Throx has decided to use the following weights in analyzing the suppliers: Supplier Characteristic Unit Price, $/3-sock set Order cost, $/order Defect Rate Financial condition of the firm Weight 0.4 0.3 0.1 0.2 Alternative Transportation An alternative to their current transportation approach available to Throx is shipment by UPS Express Air from Shanghai to Richmond, which averages 3.5 days. The comparison of costs is given as: Transporation Supplier Characteristics Units cost, $/sock set Damage Rate Average Transit time, weeks* Maersk Ocean Freight (current) $ 1.50 $ 2.0% UPS AirExpress (Alternative) 2.75 0.5% 0.5 4 * No data are available about variation in transit times, so Throx assumes this is constant. Similar to their decision about sourcing, Throx wants to use a single-sourcing strategy for transportation, so they want a recommendation about which mode would be best. Alternative Warehouse Location The company would also like to assess whether its current warehouse location is appropriate based on where customers are located. It provides you the following information about its key markets, and indicates that its orders in each market are roughly proportional to the total population. Y 40 110 Market LA-Long Beach San Francisco San Diego Sacramento Population 14,000,000 8,900,000 4,750,000 2,200,000 122 37 33 39 115 130 No late submissions will be accepted for any portion of this project. No late submission for the final version can be accepted due to deadlines for course grade submission. Please plan accordingly. For each question below complete the required calculations utilizing the tools you learned in SCM 301 providing a summary or table of your calculations. In addition, provide a few summary bullet points explaining your observations/rationale for you conclusions or recommendations. Case Questions 1) Calculate measures of forecast accuracy (MFE, MAD and MAPE) using the data from FY2016 and FY2017. Do these forecasts seem adequate for the purposes of decision making? Why or why not? Note unlike your homework/tests where we utilized multiple months this is just for the two years. 2) Develop a forecast for FY2018 using the two forecasting methods currently employed by the company. Comment on which of the forecasts is likely to be more appropriate to support decisions based on your assessment of forecast accuracy from Q1. Based upon this, identify which forecast method that you will use going forward with the project. 3) This question will have you calculating 2 EOQ and ROP values and interpreting the results. For both EOQ and ROP, give your final answer in full sock sets (ROUND UP to the next whole number). The specific questions to answer are based in parts a-c. Tips to solve the EOQ and ROP are given below in bullet points. a) Calculate EOQ and ROP for FY2017 based on the FY2017 forecast value that you recommended in Question #1. b) Calculate the EOQ and ROP based upon actual demand for FY2017 c) Using the responses from parts a & b, indicate what the implications are for inventory management costs in FY2017. In other words, 1. Compare the total costs for both EOQ values and analyze what it shows you. 2. What if any are the implications of the ROP based on the forecast vs the ROP based on actual demand. See additional tips below: Use a service level of 95% (z=1.65) when calculating the ROP Calculate average weekly demand (d) by dividing the forecast by 50 weeks For the variance in weekly demand, use the data provided in the table on page 2 of the case with the FY2017 forecast for all approaches. Remember that there is a difference between variance and standard deviation and how you apply these values in the ROP formula Annual Inventory management costs will include the following: Annual Holding Costs, Annual Ordering Costs, and Purchase Cost. . . . . . 4) Currently, the company is purchasing parts not using EOQ and ROP values determined by the tools we are using. These values are given in the case. a) Using their current order quantity, calculate the current inventory management costs based upo actual demand in FY2017 aka use this as D. b) Compare this cost to the costs to that would have been achieved if the company had used its forecast for FY2017 to calculate EOQ and ROP values (what you calculated in Question 3a). TIP: When calculating costs based upon the forecasted EOQ, use the actual demand as D in your total cost equation. This will ensure you find the true savings or increase that the company would have seen by using the EOQ value. 5) Provide the company with the following recommendations for FY2018 to improve SCM performance, based on analysis of available data and appropriate methods from SCM 301. Be sure to justify your recommendation. Use your forecast method / values from Question 2 as input into your decisions. a) Indicate which of the three suppliers should be used for FY2018. Develop a supplier scorecard using the following scale: 3=best, 2=second best, 1=worst and the weights provided in the case to support your selection. b) Calculate EOQ and ROP values for FY2018 based on your forecast from Question 2 and recommended supplier from Question 5a. (TIP: The selected supplier may change your S and P values.) Give your final answer in full sock sets (ROUND UP to the next whole number). What are the expected costs for inventory management based on your decisions? How does this compare to company's current policy-- your answers from 4a? c) Indicate which transportation mode should be used for FY2018. You must complete an analysis of the transportation costs. You may develop a scorecard to support your answer, but it is not required. When supporting your recommendation, be sure to discuss other implications (such as inventory levels, safety stock, cost etc) to support your decision. d) Indicate an appropriate location for a new facility if one is to be built using the weighted center of gravity approach. Round your final coordinates (X, Y) to two decimal places. Discuss other relevant factors that would influence the choice of a specific location once the (X,Y) coordinates have been identified. 6) Discuss potential issues with the implementation of your recommendations. What changes or resources would be necessary to implement them, and what might create challenges