Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Flow Distributor Design ( Chemical Plant Design When designing a ball plant device, we try to split the material into a distributor if possible (

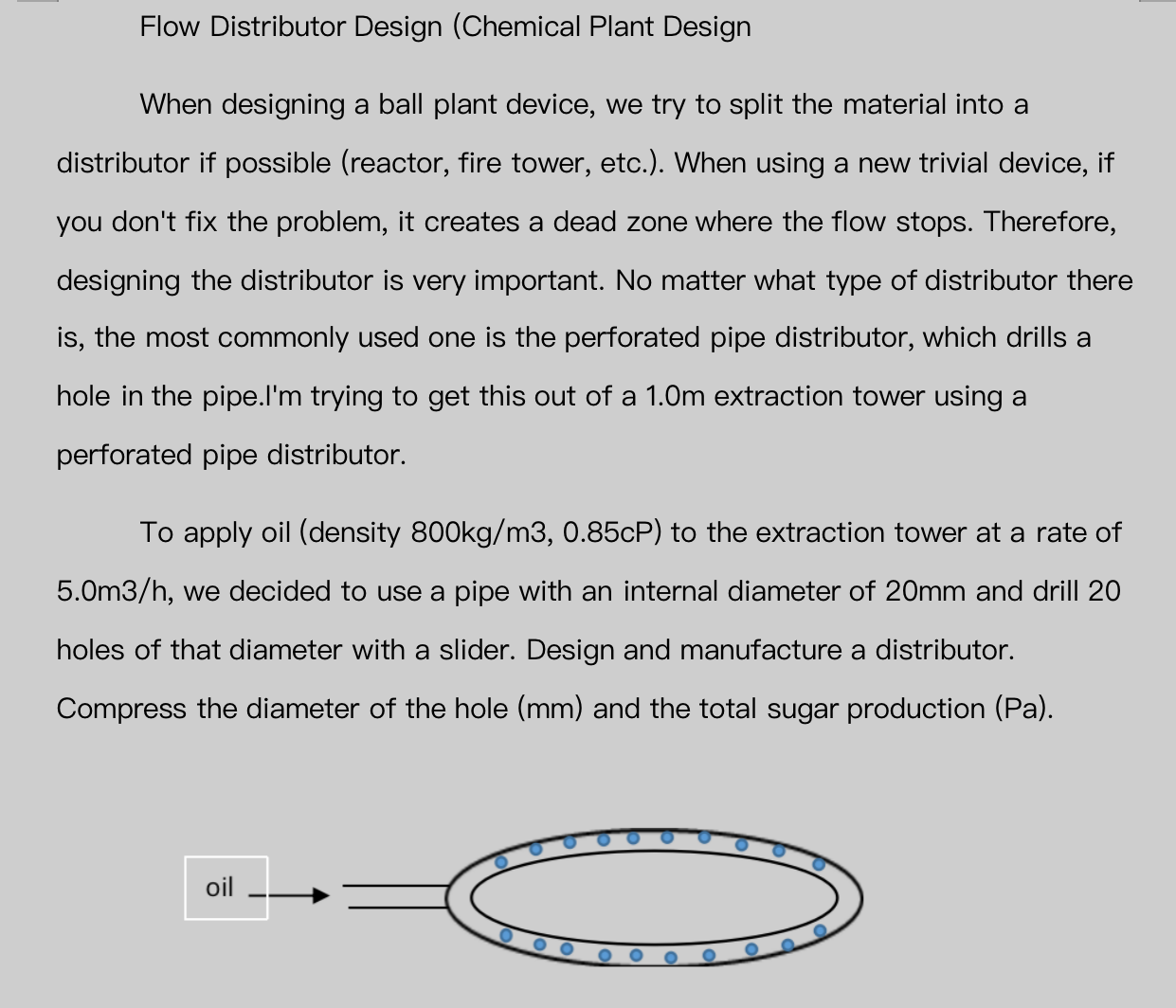

Flow Distributor Design Chemical Plant Design

When designing a ball plant device, we try to split the material into a

distributor if possible reactor fire tower, etc. When using a new trivial device, if

you don't fix the problem, it creates a dead zone where the flow stops. Therefore,

designing the distributor is very important. No matter what type of distributor there

is the most commonly used one is the perforated pipe distributor, which drills a

hole in the pipe.Im trying to get this out of a extraction tower using a

perforated pipe distributor.

To apply oil density to the extraction tower at a rate of

we decided to use a pipe with an internal diameter of and drill

holes of that diameter with a slider. Design and manufacture a distributor.

Compress the diameter of the hole and the total sugar production

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started