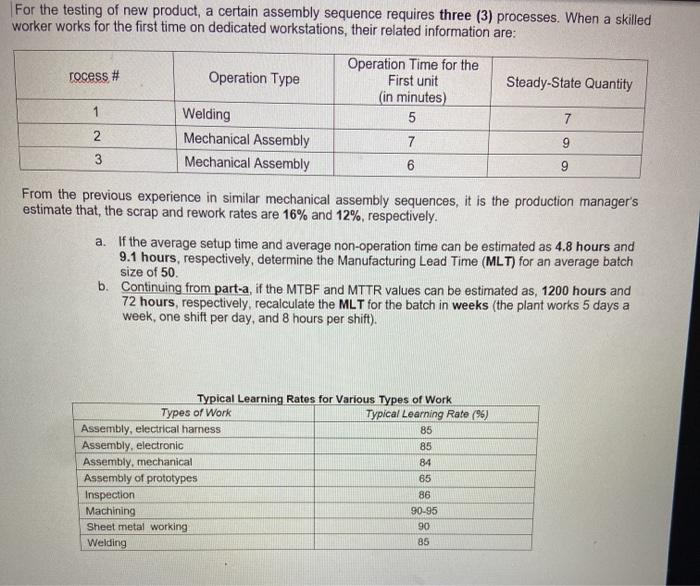

For the testing of new product, a certain assembly sequence requires three (3) processes. When a skilled worker works for the first time on dedicated workstations, their related information are: rocess # Operation Type Operation Time for the First unit (in minutes) 5 Steady-State Quantity 1 7 2 3 Welding Mechanical Assembly Mechanical Assembly 7 6 9 9 From the previous experience in similar mechanical assembly sequences, it is the production manager's estimate that the scrap and rework rates are 16% and 12%, respectively. a. If the average setup time and average non-operation time can be estimated as 4.8 hours and 9.1 hours, respectively, determine the Manufacturing Lead Time (MLT) for an average batch size of 50 b. Continuing from part-a, if the MTBF and MTTR values can be estimated as, 1200 hours and 72 hours, respectively, recalculate the MLT for the batch in weeks (the plant works 5 days a week, one shift per day, and 8 hours per shift). Typical Learning Rates for Various Types of Work Types of Work Typical Learning Rate (95) Assembly, electrical harness 85 Assembly, electronic 85 Assembly, mechanical 84 Assembly of prototypes 65 Inspection 86 Machining 90-95 Sheet metal working 90 Welding 85 For the testing of new product, a certain assembly sequence requires three (3) processes. When a skilled worker works for the first time on dedicated workstations, their related information are: rocess # Operation Type Operation Time for the First unit (in minutes) 5 Steady-State Quantity 1 7 2 3 Welding Mechanical Assembly Mechanical Assembly 7 6 9 9 From the previous experience in similar mechanical assembly sequences, it is the production manager's estimate that the scrap and rework rates are 16% and 12%, respectively. a. If the average setup time and average non-operation time can be estimated as 4.8 hours and 9.1 hours, respectively, determine the Manufacturing Lead Time (MLT) for an average batch size of 50 b. Continuing from part-a, if the MTBF and MTTR values can be estimated as, 1200 hours and 72 hours, respectively, recalculate the MLT for the batch in weeks (the plant works 5 days a week, one shift per day, and 8 hours per shift). Typical Learning Rates for Various Types of Work Types of Work Typical Learning Rate (95) Assembly, electrical harness 85 Assembly, electronic 85 Assembly, mechanical 84 Assembly of prototypes 65 Inspection 86 Machining 90-95 Sheet metal working 90 Welding 85