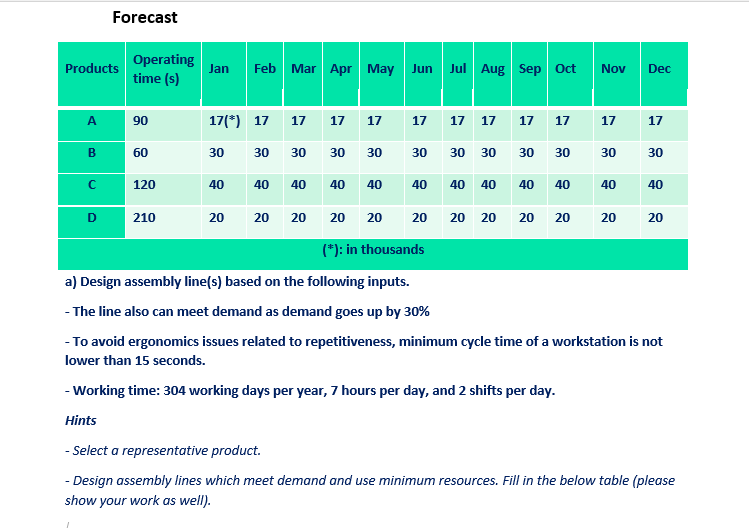

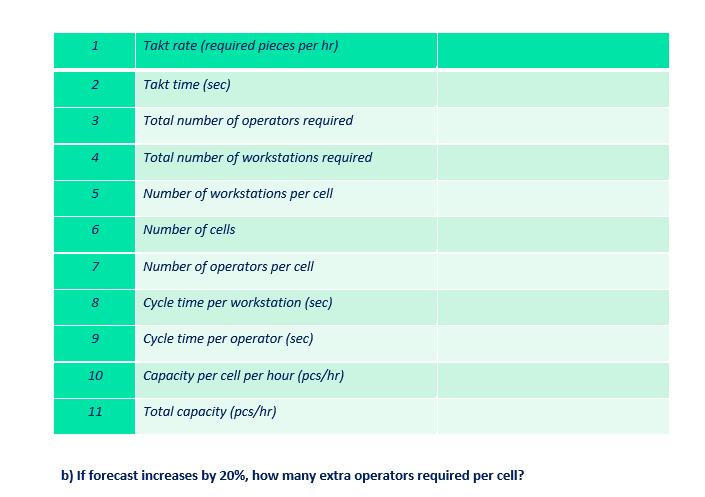

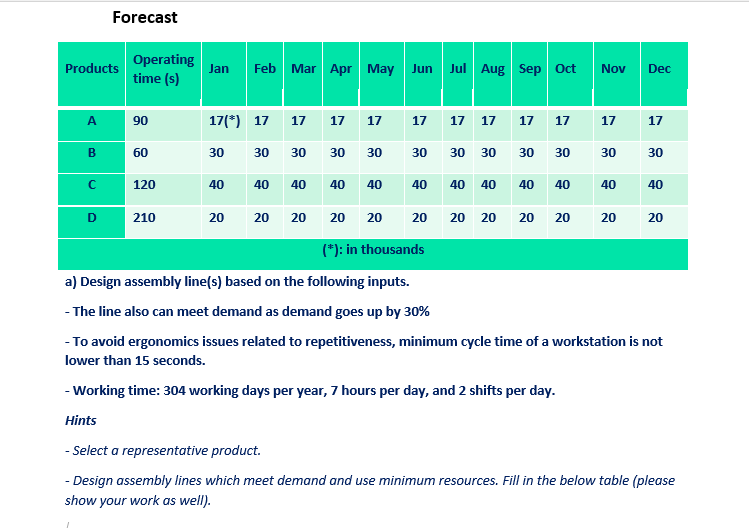

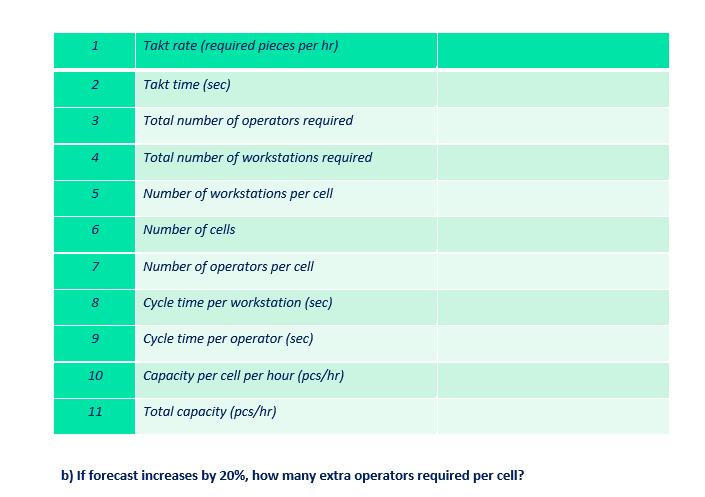

Forecast Products Operating time (s) Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec A 90 17 17 17 17 17 17 17 17 17 17(*) 17 17 30 30 B 60 30 30 30 30 30 30 30 30 30 30 120 40 40 40 40 40 40 40 40 40 40 40 40 D 210 20 20 20 20 20 20 20 20 20 20 20 20 (*): in thousands a) Design assembly line(s) based on the following inputs. - The line also can meet demand as demand goes up by 30% - To avoid ergonomics issues related to repetitiveness, minimum cycle time of a workstation is not lower than 15 seconds. - Working time: 304 working days per year, 7 hours per day, and 2 shifts per day. Hints - Select a representative product. - Design assembly lines which meet demand and use minimum resources. Fill in the below table (please show your work as well). 1 Takt rate (required pieces per hr) 2 Takt time (sec) Total number of operators required 3 4 Total number of workstations required 5 Number of workstations per cell Number of cells 7 Number of operators per cell 8 Cycle time per workstation (sec) Cycle time per operator (sec) 9 10 Capacity per cell per hour (pcs/hr) 11 Total capacity (pcs/hr) b) If forecast increases by 20%, how many extra operators required per cell? Forecast Products Operating time (s) Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec A 90 17 17 17 17 17 17 17 17 17 17(*) 17 17 30 30 B 60 30 30 30 30 30 30 30 30 30 30 120 40 40 40 40 40 40 40 40 40 40 40 40 D 210 20 20 20 20 20 20 20 20 20 20 20 20 (*): in thousands a) Design assembly line(s) based on the following inputs. - The line also can meet demand as demand goes up by 30% - To avoid ergonomics issues related to repetitiveness, minimum cycle time of a workstation is not lower than 15 seconds. - Working time: 304 working days per year, 7 hours per day, and 2 shifts per day. Hints - Select a representative product. - Design assembly lines which meet demand and use minimum resources. Fill in the below table (please show your work as well). 1 Takt rate (required pieces per hr) 2 Takt time (sec) Total number of operators required 3 4 Total number of workstations required 5 Number of workstations per cell Number of cells 7 Number of operators per cell 8 Cycle time per workstation (sec) Cycle time per operator (sec) 9 10 Capacity per cell per hour (pcs/hr) 11 Total capacity (pcs/hr) b) If forecast increases by 20%, how many extra operators required per cell