Answered step by step

Verified Expert Solution

Question

1 Approved Answer

FORECASTING AND INVENTORY MANAGEMENT AT ROHIT AUTOMOBILES INTRODUCTION On June 1, 2016, Rohit Ghosh, who had just completed the second year of his five-year

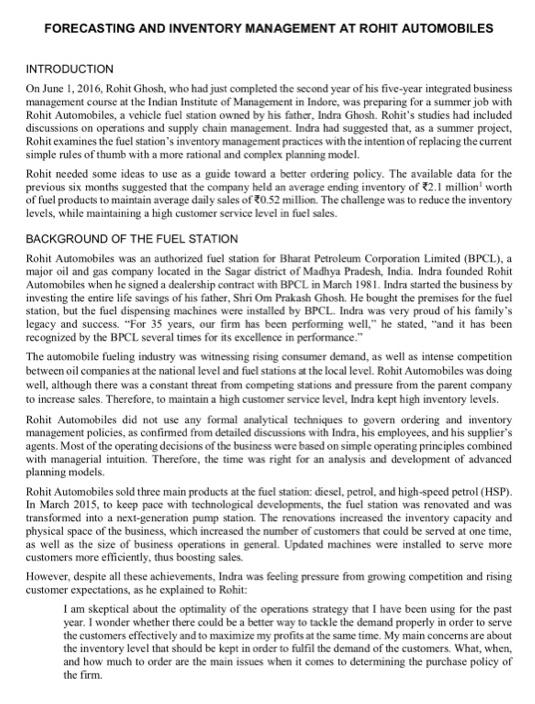

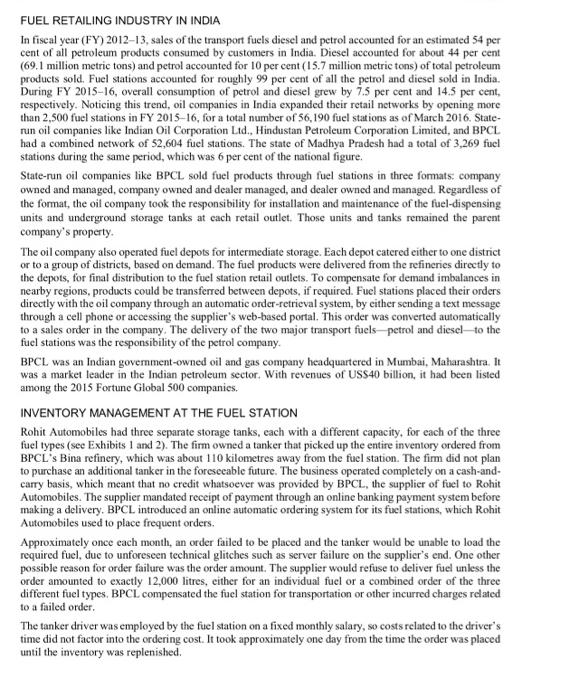

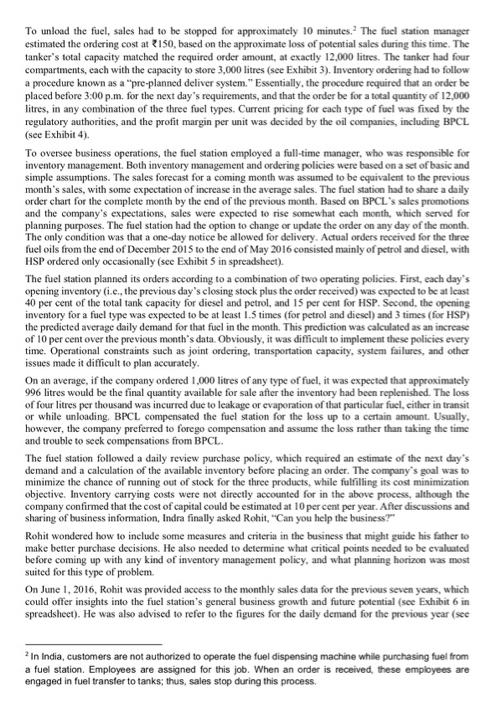

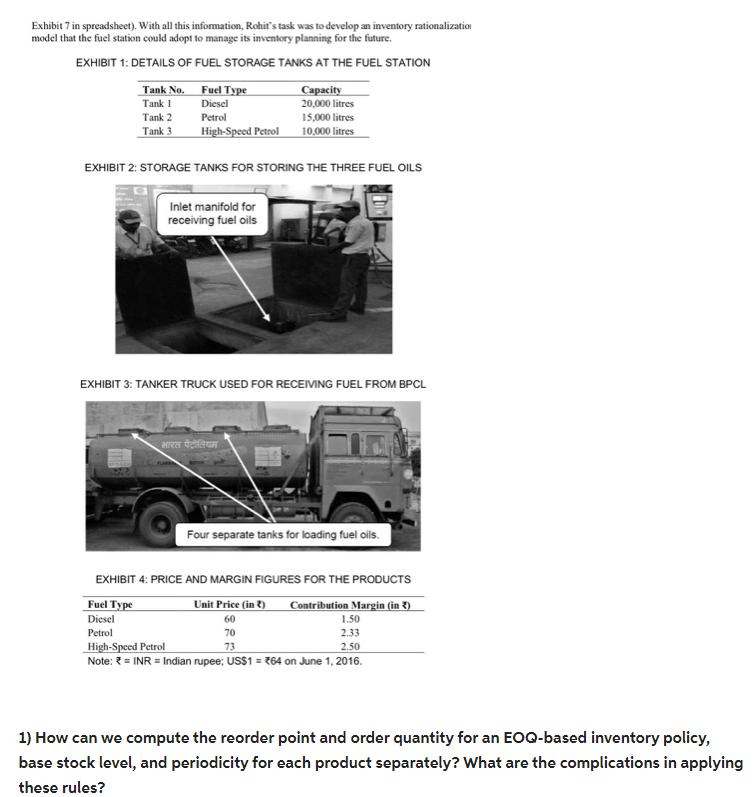

FORECASTING AND INVENTORY MANAGEMENT AT ROHIT AUTOMOBILES INTRODUCTION On June 1, 2016, Rohit Ghosh, who had just completed the second year of his five-year integrated business management course at the Indian Institute of Management in Indore, was preparing for a summer job with Rohit Automobiles, a vehicle fuel station owned by his father, Indra Ghosh. Rohit's studies had included discussions on operations and supply chain management. Indra had suggested that, as a summer project, Rohit examines the fuel station's inventory management practices with the intention of replacing the current simple rules of thumb with a more rational and complex planning model. Rohit needed some ideas to use as a guide toward a better ordering policy. The available data for the previous six months suggested that the company held an average ending inventory of 2.1 million worth of fuel products to maintain average daily sales of 20.52 million. The challenge was to reduce the inventory levels, while maintaining a high customer service level in fuel sales. BACKGROUND OF THE FUEL STATION Rohit Automobiles was an authorized fuel station for Bharat Petroleum Corporation Limited (BPCL), a major oil and gas company located in the Sagar district of Madhya Pradesh, India. Indra founded Rohit Automobiles when he signed a dealership contract with BPCL in March 1981. Indra started the business by investing the entire life savings of his father, Shri Om Prakash Ghosh. He bought the premises for the fuel station, but the fuel dispensing machines were installed by BPCL. Indra was very proud of his family's legacy and success. "For 35 years, our firm has been performing well," he stated, "and it has been recognized by the BPCL several times for its excellence in performance." The automobile fueling industry was witnessing rising consumer demand, as well as intense competition between oil companies at the national level and fuel stations at the local level. Rohit Automobiles was doing well, although there was a constant threat from competing stations and pressure from the parent company to increase sales. Therefore, to maintain a high customer service level, Indra kept high inventory levels. Rohit Automobiles did not use any formal analytical techniques to govern ordering and inventory management policies, as confirmed from detailed discussions with Indra, his employees, and his supplier's agents. Most of the operating decisions of the business were based on simple operating principles combined with managerial intuition. Therefore, the time was right for an analysis and development of advanced planning models. Rohit Automobiles sold three main products at the fuel station: diesel, petrol, and high-speed petrol (HSP). In March 2015, to keep pace with technological developments, the fuel station was renovated and was transformed into a next-generation pump station. The renovations increased the inventory capacity and physical space of the business, which increased the number of customers that could be served at one time, as well as the size of business operations in general. Updated machines were installed to serve more customers more efficiently, thus boosting sales. However, despite all these achievements, Indra was feeling pressure from growing competition and rising customer expectations, as he explained to Rohit: I am skeptical about the optimality of the operations strategy that I have been using for the past year. I wonder whether there could be a better way to tackle the demand properly in order to serve the customers effectively and to maximize my profits at the same time. My main concerns are about the inventory level that should be kept in order to fulfil the demand of the customers. What, when, and how much to order are the main issues when it comes to determining the purchase policy of the firm. FUEL RETAILING INDUSTRY IN INDIA In fiscal year (FY) 2012-13, sales of the transport fuels diesel and petrol accounted for an estimated 54 per cent of all petroleum products consumed by customers in India. Diesel accounted for about 44 per cent (69.1 million metric tons) and petrol accounted for 10 per cent (15.7 million metric tons) of total petroleum products sold. Fuel stations accounted for roughly 99 per cent of all the petrol and diesel sold in India. During FY 2015-16, overall consumption of petrol and diesel grew by 7.5 per cent and 14.5 per cent, respectively. Noticing this trend, oil companies in India expanded their retail networks by opening more than 2,500 fuel stations in FY 2015-16, for a total number of 56, 190 fuel stations as of March 2016. State- run oil companies like Indian Oil Corporation Ltd., Hindustan Petroleum Corporation Limited, and BPCL had a combined network of 52,604 fuel stations. The state of Madhya Pradesh had a total of 3,269 fuel stations during the same period, which was 6 per cent of the national figure. State-run oil companies like BPCL sold fuel products through fuel stations in three formats: company owned and managed, company owned and dealer managed, and dealer owned and managed. Regardless of the format, the oil company took the responsibility for installation and maintenance of the fuel-dispensing units and underground storage tanks at each retail outlet. Those units and tanks remained the parent company's property. The oil company also operated fuel depots for intermediate storage. Each depot catered either to one district or to a group of districts, based on demand. The fuel products were delivered from the refineries directly to the depots, for final distribution to the fuel station retail outlets. To compensate for demand imbalances in nearby regions, products could be transferred between depots, if required. Fuel stations placed their orders directly with the oil company through an automatic order-retrieval system, by either sending a text message through a cell phone or accessing the supplier's web-based portal. This order was converted automatically to a sales order in the company. The delivery of the two major transport fuels petrol and diesel to the fuel stations was the responsibility of the petrol company. BPCL was an Indian government-owned oil and gas company headquartered in Mumbai, Maharashtra. It was a market leader in the Indian petroleum sector. With revenues of USS40 billion, it had been listed among the 2015 Fortune Global 500 companies. INVENTORY MANAGEMENT AT THE FUEL STATION Rohit Automobiles had three separate storage tanks, each with a different capacity, for each of the three fuel types (see Exhibits 1 and 2). The firm owned a tanker that picked up the entire inventory ordered from BPCL's Bina refinery, which was about 110 kilometres away from the fuel station. The firm did not plan to purchase an additional tanker in the foreseeable future. The business operated completely on a cash-and- carry basis, which meant that no credit whatsoever was provided by BPCL, the supplier of fuel to Rohit Automobiles. The supplier mandated receipt of payment through an online banking payment system before making a delivery. BPCL introduced an online automatic ordering system for its fuel stations, which Rohit Automobiles used to place frequent orders. Approximately once each month, an order failed to be placed and the tanker would be unable to load the required fuel, due to unforeseen technical glitches such as server failure on the supplier's end. One other possible reason for order failure was the order amount. The supplier would refuse to deliver fuel unless the order amounted to exactly 12,000 litres, either for an individual fuel or a combined order of the three different fuel types. BPCL compensated the fuel station for transportation or other incurred charges related to a failed order. The tanker driver was employed by the fuel station on a fixed monthly salary, so costs related to the driver's time did not factor into the ordering cost. It took approximately one day from the time the order was placed until the inventory was replenished. To unload the fuel, sales had to be stopped for approximately 10 minutes. The fuel station manager estimated the ordering cost at 150, based on the approximate loss of potential sales during this time. The tanker's total capacity matched the required order amount, at exactly 12,000 litres. The tanker had four compartments, each with the capacity to store 3,000 litres (see Exhibit 3). Inventory ordering had to follow a procedure known as a "pre-planned deliver system." Essentially, the procedure required that an order be placed before 3:00 p.m. for the next day's requirements, and that the order be for a total quantity of 12,000 litres, in any combination of the three fuel types. Current pricing for each type of fuel was fixed by the regulatory authorities, and the profit margin per unit was decided by the oil companies, including BPCL (see Exhibit 4). To oversee business operations, the fuel station employed a full-time manager, who was responsible for inventory management. Both inventory management and ordering policies were based on a set of basic and simple assumptions. The sales forecast for a coming month was assumed to be equivalent to the previous month's sales, with some expectation of increase in the average sales. The fuel station had to share a daily order chart for the complete month by the end of the previous month. Based on BPCL's sales promotions and the company's expectations, sales were expected to rise somewhat each month, which served for planning purposes. The fuel station had the option to change or update the order on any day of the month. The only condition was that a one-day notice be allowed for delivery. Actual orders received for the three fuel oils from the end of December 2015 to the end of May 2016 consisted mainly of petrol and diesel, with HSP ordered only occasionally (see Exhibit 5 in spreadsheet). The fuel station planned its orders according to a combination of two operating policies. First, each day's opening inventory (i.c., the previous day's closing stock plus the order received) was expected to be at least 40 per cent of the total tank capacity for diesel and petrol, and 15 per cent for HSP. Second, the opening inventory for a fuel type was expected to be at least 1.5 times (for petrol and diesel) and 3 times (for HSP) the predicted average daily demand for that fuel in the month. This prediction was calculated as an increase of 10 per cent over the previous month's data. Obviously, it was difficult to implement these policies every time. Operational constraints such as joint ordering, transportation capacity, system failures, and other issues made it difficult to plan accurately. On an average, if the company ordered 1,000 litres of any type of fuel, it was expected that approximately 996 litres would be the final quantity available for sale after the inventory had been replenished. The loss of four litres per thousand was incurred due to leakage or evaporation of that particular fuel, either in transit or while unloading. BPCL compensated the fuel station for the loss up to a certain amount. Usually. however, the company preferred to forego compensation and assume the loss rather than taking the time and trouble to seek compensations from BPCL. The fuel station followed a daily review purchase policy, which required an estimate of the next day's demand and a calculation of the available inventory before placing an order. The company's goal was to minimize the chance of running out of stock for the three products, while fulfilling its cost minimization objective. Inventory carrying costs were not directly accounted for in the above process, although the company confirmed that the cost of capital could be estimated at 10 per cent per year. After discussions and sharing of business information, Indra finally asked Rohit, "Can you help the business?"" Rohit wondered how to include some measures and criteria in the business that might guide his father to make better purchase decisions. He also needed to determine what critical points needed to be evaluated before coming up with any kind of inventory management policy, and what planning horizon was most suited for this type of problem. On June 1, 2016, Rohit was provided access to the monthly sales data for the previous seven years, which could offer insights into the fuel station's general business growth and future potential (see Exhibit 6 in spreadsheet). He was also advised to refer to the figures for the daily demand for the previous year (see 2 In India, customers are not authorized to operate the fuel dispensing machine while purchasing fuel from a fuel station. Employees are assigned for this job. When an order is received, these employees are engaged in fuel transfer to tanks; thus, sales stop during this process. Exhibit 7 in spreadsheet). With all this information, Rohit's task was to develop an inventory rationalization model that the fuel station could adopt to manage its inventory planning for the future. EXHIBIT 1: DETAILS OF FUEL STORAGE TANKS AT THE FUEL STATION Tank No. Tank 1 Tank 2 Tank 3 Fuel Type Diesel Petrol High-Speed Petrol EXHIBIT 2: STORAGE TANKS FOR STORING THE THREE FUEL OILS Inlet manifold for receiving fuel oils Capacity 20,000 litres 15,000 litres 10,000 litres EXHIBIT 3: TANKER TRUCK USED FOR RECEIVING FUEL FROM BPCL azer destr Four separate tanks for loading fuel oils. EXHIBIT 4: PRICE AND MARGIN FIGURES FOR THE PRODUCTS Fuel Type Contribution Margin (in 2) Unit Price (in) 60 Diesel 1.50 Petrol 70 2.33 73 High-Speed Petrol 2.50 Note: * = INR - Indian rupee; US$1 = 264 on June 1, 2016. 1) How can we compute the reorder point and order quantity for an EOQ-based inventory policy, base stock level, and periodicity for each product separately? What are the complications in applying these rules?

Step by Step Solution

★★★★★

3.21 Rating (151 Votes )

There are 3 Steps involved in it

Step: 1

The detailed ...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started