Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Friction stir welding is a solid-state welding process which has gained enormous popularity since the late 1990s, particularly for welding aluminum alloys. Consider the

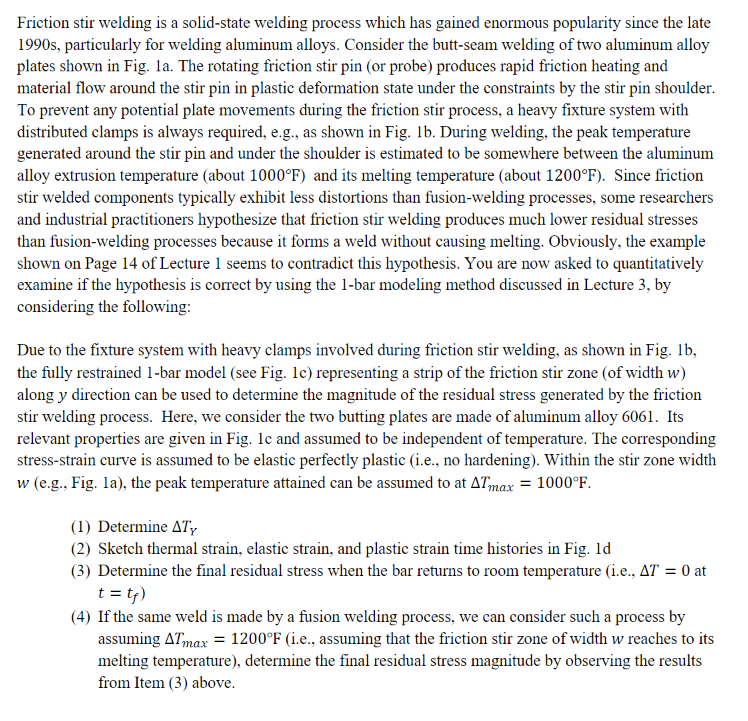

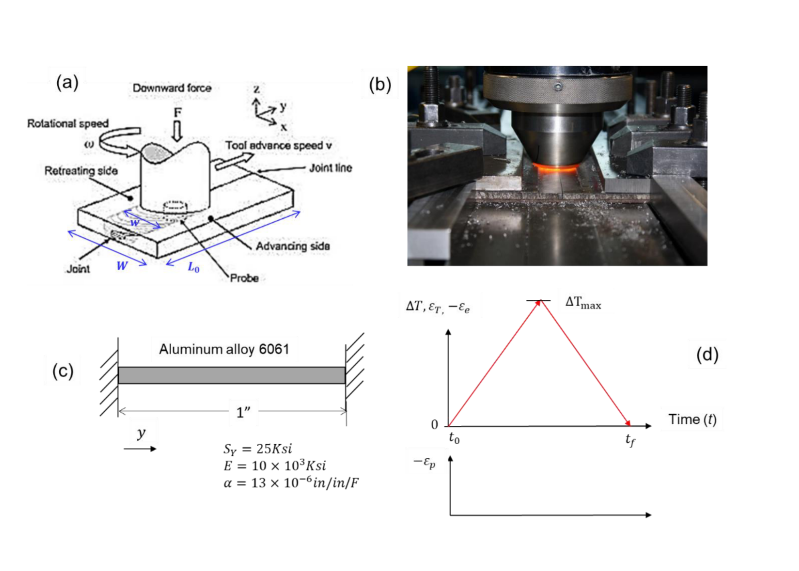

Friction stir welding is a solid-state welding process which has gained enormous popularity since the late 1990s, particularly for welding aluminum alloys. Consider the butt-seam welding of two aluminum alloy plates shown in Fig. 1a. The rotating friction stir pin (or probe) produces rapid friction heating and material flow around the stir pin in plastic deformation state under the constraints by the stir pin shoulder. To prevent any potential plate movements during the friction stir process, a heavy fixture system with distributed clamps is always required, e.g., as shown in Fig. 1b. During welding, the peak temperature generated around the stir pin and under the shoulder is estimated to be somewhere between the aluminum alloy extrusion temperature (about 1000F) and its melting temperature (about 1200F). Since friction stir welded components typically exhibit less distortions than fusion-welding processes, some researchers and industrial practitioners hypothesize that friction stir welding produces much lower residual stresses than fusion-welding processes because it forms a weld without causing melting. Obviously, the example shown on Page 14 of Lecture 1 seems to contradict this hypothesis. You are now asked to quantitatively examine if the hypothesis is correct by using the 1-bar modeling method discussed in Lecture 3, by considering the following: Due to the fixture system with heavy clamps involved during friction stir welding, as shown in Fig. 1b, the fully restrained 1-bar model (see Fig. 1c) representing a strip of the friction stir zone (of width w) along y direction can be used to determine the magnitude of the residual stress generated by the friction stir welding process. Here, we consider the two butting plates are made of aluminum alloy 6061. Its relevant properties are given in Fig. 1c and assumed to be independent of temperature. The corresponding stress-strain curve is assumed to be elastic perfectly plastic (i.e., no hardening). Within the stir zone width w (e.g., Fig. 1a), the peak temperature attained can be assumed to at ATmax = 1000F. (1) Determine ATY (2) Sketch thermal strain, elastic strain, and plastic strain time histories in Fig. 1d (3) Determine the final residual stress when the bar returns to room temperature (i.e., AT = 0 at t = tf) (4) If the same weld is made by a fusion welding process, we can consider such a process by assuming ATmax = 1200F (i.e., assuming that the friction stir zone of width w reaches to its melting temperature), determine the final residual stress magnitude by observing the results from Item (3) above. (a) Rotational speed Downward force Retreating side Tool advance speed v Joint line Joint Lo (c) Probe Advancing side Aluminum alloy 6061 1" Sy = 25Ksi E = 10 x 10 Ksi a = 13 x 10-bin/in/F (b) ATmax AT, ET. -Ee (d) Time (t) 0 tf to -Ep

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started