Answered step by step

Verified Expert Solution

Question

1 Approved Answer

From the attached...... a) What is the significance of the paper b) What you have learned from the paper c) Any suggestions for improvement d)

From the attached......

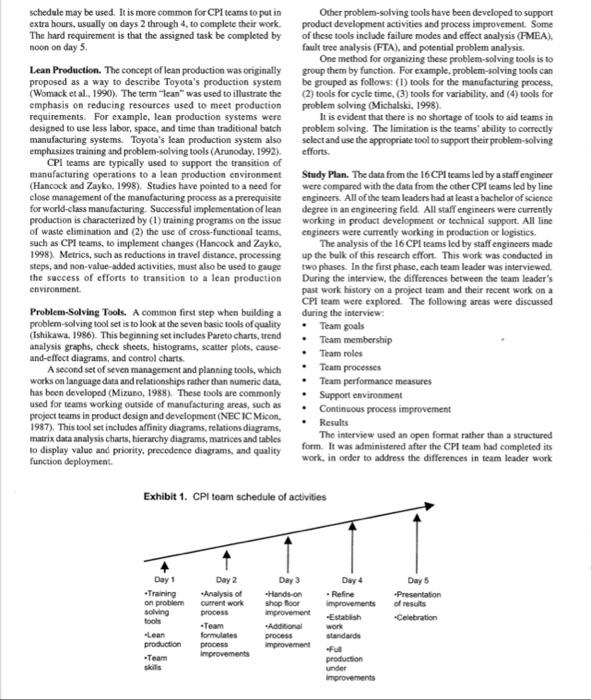

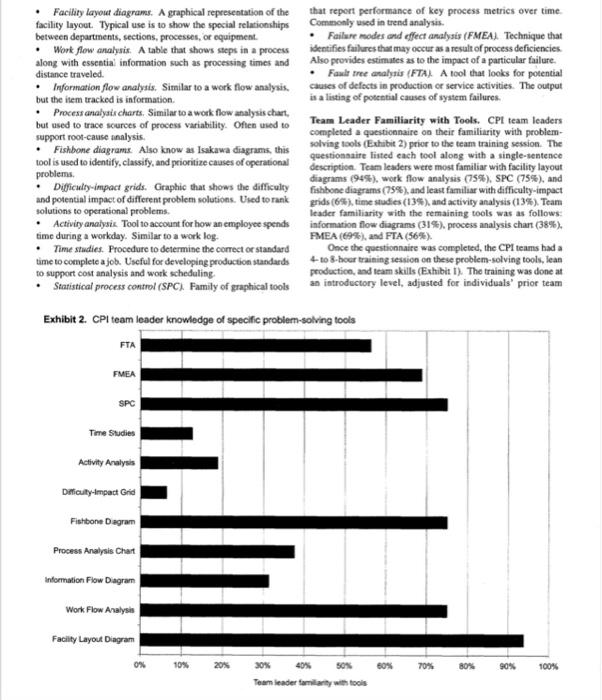

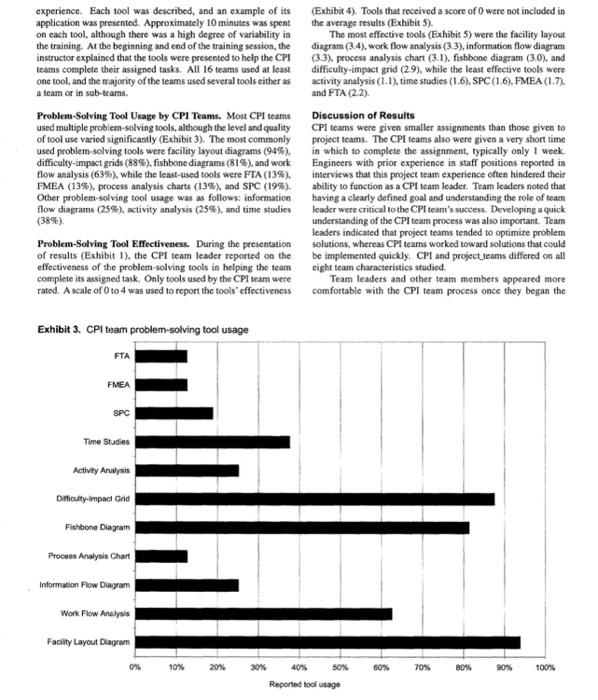

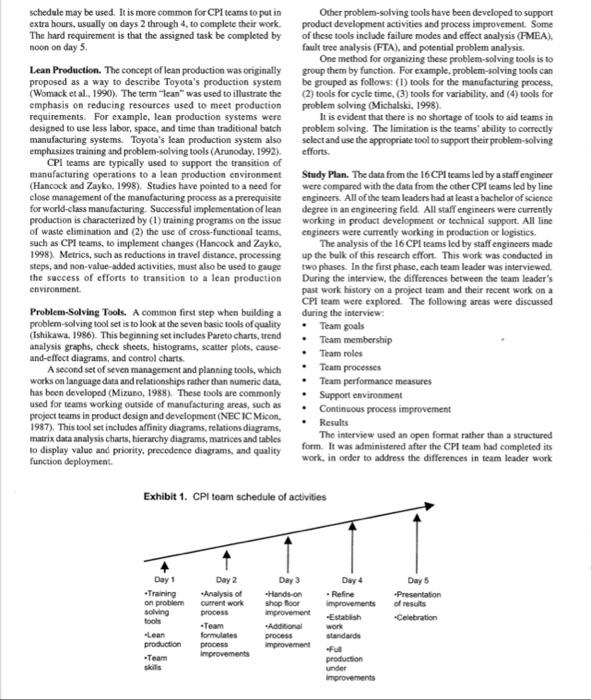

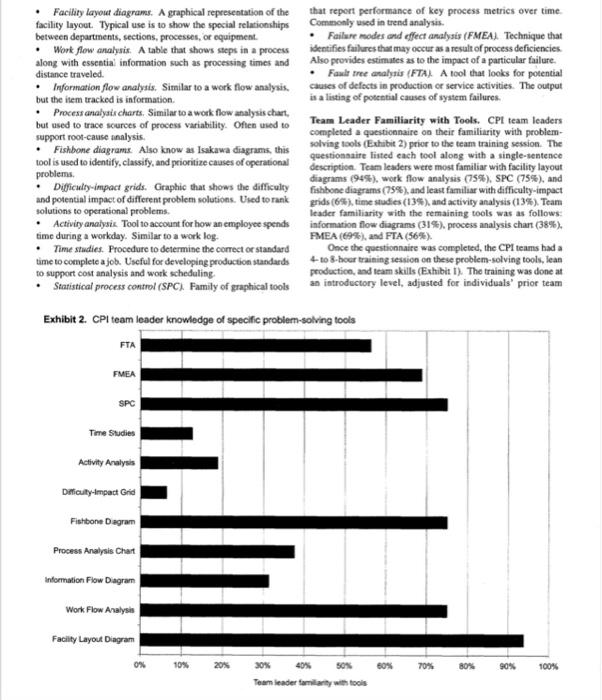

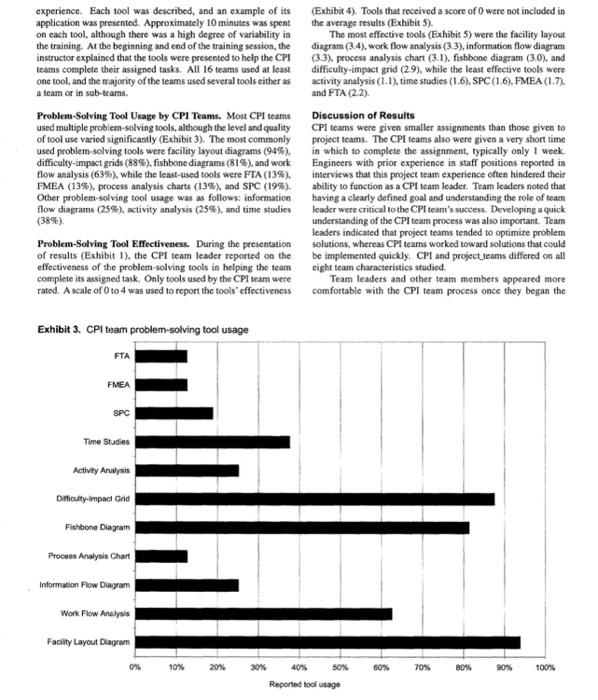

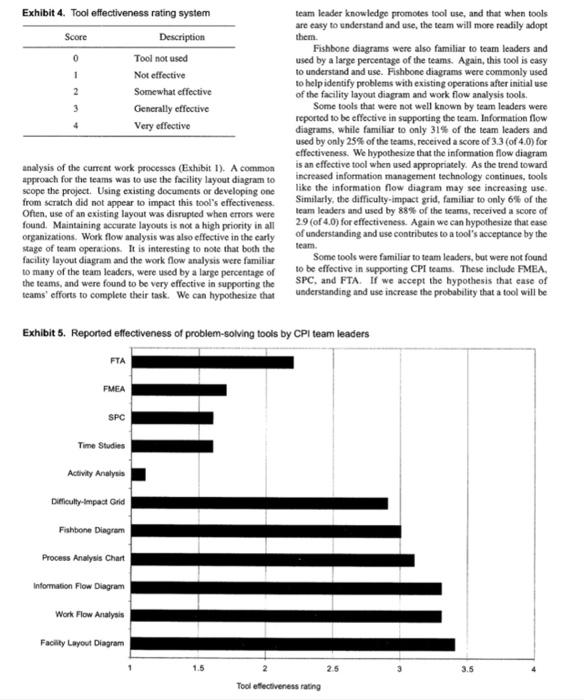

IDENTIFICATION OF EFFECTIVE PROBLEM-SOLVING TOOLS TO SUPPORT CONTINUOUS PROCESS IMPROVEMENT TEAMS Abstract the engineers had been involved in the past, asd the use of different Continuous process improvement (CPI) teams function differently problem-solving tools by the CPI teams for task completion. than other project teams. Therefore, engineers who are called on The goals of this stady were (1) to gather information on to support CPI teams may need to utilize different tool sets if they differences between CPI and traditional project teams, and (2) to are to be cffective in improving manufacturing operations. This. identify problem-solving tools ased by the CPI teams. Information article explores the differences between CPI teams and traditional was gathered from CPI team leaders. The primary data collection project teams. It also reports on the initial identification of methods used were interviews and questionsaires. problem-solving tools that meet the needs of CPI teams, and reports preliminary findings on their usefulness and applicability. CPI Team Operations. CPI teams were expected to complete Data from our 2-year study of 16 CPI teams working in light their tasks within 5 days (Exhibit 1). This time frame was manufacturing, logisties, and automotive assembly show that tool established to limit the scope and cost of the CPI team activity. In selection is influenced by team life span, data availability, and the majority of cases (30 of 31), the CPI team was a pilot team team member skill level. This stady also found that the primary that was the first attempt by the organizaticn to implement lean factors influencing tool effectiveness are team member training manufacturing principles in the operation. The team schedule and the time required for data analysis. includes 4 to 8 hours of training. 24 to 28 hours of direct work on the task, and a 4-hour closecet. There was a high degree of Introduction variability is team operations. For smaller tasks, a 3-or 4-day Goals of this Study. A set of 31 continuous process improvement (CPI) teams was formed to improve the effectiveness of manufacturing operations. While each of the teams operated for only I week, the study took place over a 2-year period, from May 1996 through July 1998 . The CPI teams were formed to support implementation of lean production techniques. The effectiveness of a CPI team was measured with three metrics: redoction in total travel distance for the product, percent reduction in the number of total processing steps, and percent reduction in the number of non-value-added seeps. Travel distance was measured in feet. The number of steps in the process was determined by identifying the number of operations, inspections, delays, movements, and storages the product goes through. An operation was defined as a value-added activiry, while all other activities were defined as non-value added, This article reports on the effectiveness of a subset of 16 teams selected from the original 31 CPI teams. While all the teams were led by enginoers, these 16 teams were led by cngincers who were not experienced in direct line operations but, rather, worked in staff operations such as product development and product technical support. The 16 teams included 11 in light manufacturing, 3 in logistics, and 2 in automotive assembly. This subset of 16 teams was of interest because these teams showed a higher degree of variability in their effectiveness than did the larger set of 31 teams. CPI teams led by staff engincers were found to perform cither significantly better or significantly poorer than CPI teams led by line engineers. Reviews pointed to two factors that influenced the high variability in team effectiveness: diflerences betwcen CPI tearns and the traditional project tearns with which schedale may be used. It is more common for CPI teams to pot in Other problem-solving tools have been developed to support extra hours, usually on days 2 through 4 , to complete their work. product development activities and process improvement. Some The hard requirement is that the assigned task be completed by of these tools include failure modes and effect analysis (FMEA). noon on day 5. fault tree analysis (FTA), and potential problem analysis. One method for organizing these problem-solving tools is to Lean Production. The concept of lean production was originally group them by function. For example, problem-solving tools can proposed as a way to describe Toyota's production system be grouped as follows: (1) toots for the nanufacturing process, (Womack et al. 1990). The term "lean" was esed to illustrate the (2) tools for cycle time, (3) tools for variability, and (4) tools for emphasis on reducing resources used to meet production problem solving (Michalski, 1998). requirements. For example, lean production systems were It is evident that there is no shortage of tools to aid teams in designed to use less labor, space, and time than traditional batch problem solving. The limitation is the teams' ability to correctly manufacturing systems. Toyota's lean production system atso select and use the appropriate tool to support their problem-solving emphasizes training and problem-solving tools (Arunoday, 1992). efforts. CPl teams are typically used to support the transition of manufacturing operations to a lean production environment Study Plan. The data from the 16 CPI teams led by a staff engineer (Hancock asd Zayko, 1998). Studies have pointed to a need for were compared with the data from the other CPI teams led by line close management of the manufacturing process as a prerequisite_ engincers. All of the team leaders had at least a bachelor of science for world-class manufacturing. Successful implementation of lean degree in an engineering field. All staff engineers were currently production is characterized by (1) training programs on the issue working in product development or technical support. All line of waste elimination and (2) the use of cross-functional teams, engineers were currently working in production or logistics. such as CP1 teams, to implement changes (Hancock and Zayko, The analysis of the 16 CPI teams led by staff engineers. made 1998). Metrics, such as reductions in travel distance, processing up the bulk of this research effort. This work was conducted in steps, and non-value-added activities, must also be used to gauge two phases. In the first phase, each team leader was interviewed. the success of efforts to transition to a lean production During the interview, the differences between the team leader's environment. past work history on a project team and their recent work on a CP1 team were explored. The following areas were discussed Problem-Solving Tooks. A common first step when building a during the interview: problem-solving tool set is to look at the seven basic tools of quality - Team goals (Ishikawa, 1986). This beginning set includes Paretocharts, trend - Team membership analysis graphs, check sheets, histograms, scatter plots, caase- - Team roles and-effect diagrams, and control charts. - Team processes A second set of seven management and plansing tools, which - Team performance measures works on language data and relationships rather than numeric data. - Support environmeat used for teams working outside of manufacturing areas, such as - Continsous process improvement project teams in product design and development (NEC IC Micon, - Results 1987). This tool set includes affinity diagrams, relations diagrams, The interview used an open format rather than a structured matrix data analysis charts, hierarchy diagrams, matrices and tables to display value and priority, precedence diagrams, and quality form. It was administered after the CPI team had completed its function deployment. work, in order to address the differences in team leader work experience, formal education, and experience with teams. The - Team roles. At team launch, the only role that is typically information collected in this format was qualitative, not defined on a CPI team is that of leader. This position was selected quantitative. In the second phase, each team Ieader completed a operations. In project teams, more roles are defined and team questionnaire. The questionnaire asked the leaders to identify members may shift roles as the team develops. The longer a project how familiar they were with each quality tool, whether they used team operates, the greater the likelihood that team roles will the quality tool during CPI operations, and how successful the change. Project teams with extended operations may face tool was in supporting the CPI team. The questionaire was significast problems due to team member rotations on and off the completed immed ately after the interview. The interviews lasted from 30 to 95 minutes, with an average take on informal roles that were not originally included in the time of 44 minutes. Team leaders completed the questionnaire in team charter. For example, project team members may become 15 to 24 minutes, with an average time of 18 minutes. Interviews liaisons with external vendors, provide support to other team and questionnaires were successfully conducted with all 16CPI members on software issues, or be resident experts on specific team leaders. technologies. These informal roles were not as common with Research Results Differences between CPI and Project Teams. On the surface, - Team processes. CPI processes are fypically defined outside CPI teams differ from project teams primarily in the duration of the team and communicated to members by the leader and through team activities and the size and scope of the tasks undertaken. A. orientation training at the beginning of team cperations. This is CPI team is typically used to support improvements in always the case for personel who have not been on a team in the manufacturing operations. The CPI team is given a specific task past. Due to time constraints, the CPI team does not develop new to accomplish in a set time, measured in days. A project team is processes to support their operations. CPI teams also tend to focus used to support research and development of an artifact, so it on the assignod task. Project teams can begin with extemally. performs a greater number and variety of tasks than does a CPI defined processes but are able to develop iaternal processes to team. The project duration is also longer, measured in months or meet team neods. Project teams focus on both the task and the years. process used to complete the task. These differences in types of tasks assigned and duration of - Team performance measures. A CPI team's performance is team effort have a much more pronounced impact on team typically based on accomplishment of the assigned task. Typical operations than is often recognized. This impact can be better measares for CPI teams focus on manufacturing process explained by looking at specific characteristics of teams. CPI improvemeats like reductioas in cycle time, travel distance, setup team leaders reported the following differences between their CPI timo, and the number of process steps. A typical CPI team does team activities and their past experience with project teams. not have process-orieated measures, while project teams typically - Team goals. CPI teams typically have a single, well-defined have both process and product measures. Process measures goal, and the team can determine how to measure its attainment. include families of metrics focusing on schedule and bodget. For example, a common CPI team task is to reduce processing. Product measures include metrics such as reducing techaical risk time in a department. The CPI team may measure its performance and achieving performance design targets. with several different metrics, including reduction in cycle time * Support environment. CPI team members use existing to complete a unit of productioa, decrease in usit travel distance, organizational resources and rarely have additional resources and the amount of non-value-added time a unit spends in a allocated to support completion of their task. Project teams department. The goal is established outside the team, and team typically operate with an independent bodget that allows for members generally are not asked to accept, modify, or reject the expenses in manpower, equipenent (hardware and software) and. goal. A project team's goal is typically defined both outside and inside the team; metrics for measuring team performance are also - Continuous process improvement. CPI teams are focused on developed is this way. Team members review and accepe the task completion. Process improvement, if it occurs, usually takes goal. Throughout the project, the goal is often reviewed asd the form of gathering lessons learned for future CPI teams. Project modified by the project team. the team. Team member roles are defined by functional area. For _ - Results. CPI team results had a high degree of variability. example, a typical 8-person CPI team consisted of 4 operators The biegest predictors of team success reported by CPI team from the production area the team was working on. The remaining leaders were the support provided by the pareat organization to team members typisally included a project engineer as team lead, the team and the skills of team members; the ability to function as a second administrative team member from accountisg or a team, while important, was not as critical a predictor of team purchasing, and personnel from quality and maintenance. Project success. Project team results are also affected by the parent team membership is determined inside and outside the team. The organization's support, team members' skills, and the team's ability team may elect to add or remove members as the work tasks to function effectively. become better defined and some tasks aee corppleted. It is more common to add than to remove team members. Individual team . Problem-Solving Tool Use and Effectiveness. The following members' roles also shift from representing functional areas to problem-solving tools were provided to the CPI teams for ese contributing to tean goals rather than functional goals. - Facility layout diagrams. A graphical representation of the that report performance of key process metries over time. facility luyoot. Typical use is to show the spocial relationships Commonly used in trend analysis. between departments, sections, processes, or equipment. - Failure modes and offect analysis (FMEA). Technique that - Work flow analysis. A table that shows steps in a process identifies falures that may occur as a result of process deficiencies. along with essestial information such as processing times and Also provides estimates as to the impact of a particular failure. distance traveled. - Faulr tree analynis (FIA). A tool that looks for potential - Information flow analysis. Similar to a work flow analysis, causes of defocts in production or service activities. The output but the inem tracked is information. - Process analyain charts. Similar to a work flew analysis chart, is a listisg of potential causes of system failures. but used to trace scuroes of process variability. Often used to . Team Leader Familiarity with Tools. CPI team leaders support root-cause analysis. completed a questionnaire on their familiarity with problem- - Fishbone diagrams. Also know as Isakawa diagrams, this solving tools (Exhibit 2) prior to the team trainiag session. The tool is used to identify, classify, and prioritize causes of operational questionsaire litted each tool along with a single-sentence problems. - Difficulty-impact grids. Graphic that shows the difficulty fiagrams (94\%), werk flow analysis (75\%), SPC (75\%), and (fahbone diagrams (75\%), and least familaar with difficulty-impact descriptice. Team leaders were most familiar with facility layout and potential impact of different problem solutions. Used to rank grids (6%), time studies (13\%), and activity analysis (13\%). Team solutions to operational problems. leader familiarity with the remaining tools was as follows: - Activiry analysis. Tool to account for how an employee spends information flow diagrams (31\%), process analysis chart (38\%). time during a workday. Similar to a work log. FMEA (69%), and FTA ( 56%). - Time stadies. Procedure to determine the comect or standard Once the qaestionnaire was completed, the CPI teams had a time to complete a job. Useful for developing production standards 4- to 8.bour training session on these problem-solving tools, lean to support cost analysis and work scheduling. productice, and team skills (Exhibit I). The training was done at - Statistical process control (SPC). Family of graphical tools an introductory level, adjusted for individuals' prior team experience. Each tool was described, and an example of its (Exhibit 4). Tools that received a score of 0 were not included in application was presented. Approximately 10 minutes was speat the average results (Exhibit 5 ). on each tool, although there was a high degree of variability ia The most effective tools (Exhibit 5) were the facility layout the training. At the beginning and end of the training session, the diagram (3.4), work flow analysis {3.3), information flow diagram instructor explained that the tools were presented to help the CPI (3.3), process analysis chart (3.1), fishbone diagram (3.0), and teams complete their assigned tasks. All 16 teams used at least difficulty-impact grid (2.9), while the least effective tools were one tool, and the majority of the teams used several tools either as activity analysis (1.1), time studies (I.6), SPC (1.6), FMEA (1.7). a team or in sub-teams. and FTA (2.2). Problem-Solving Tool Usage by CPI Teams. Most CP1 teams Discussion of Results used multiple probiem-solving tools, although the level and quality CPI teams were given smaller assignments than those given to of tool use varied significantly (Exhibit 3). The most commonly project teams. The CPI teams also were given a very short time used problem-solving tools were facility layout diagrams (94\%), in which to complete the assignment, typically only 1 week. difficulty-impact grids (88%), fishbone diagrams (81%), and work Engineers with prior experience in staff positions reported in flow analysis (63\%), while the least-used tools were FIA (13\%), interviews that this project team experience often hindered their FMEA (13\%), process analysis charts (13%), and SPC (19\%). ability to function as a CP1 team leader. Team leaders noted that Other problem-solving tool usage was as follows: information having a clearly defined goal and usderstanding the role of team flow diagrams (25%), activity analysis (25%), and time studies leader were critical to the CPI team's success. Developing a quick (38\%). understanding of the CPI team process was also important. Team leaders indicated that project teams tended to optimize problem Problem-Solving Tool Effectiveness. During the presentation solutions, whereas CPI teams worked toward solutions that could of results (Exhibit 1), the CPI team leader reported on the be implemented quickly, CPI and project_teams differed on all effectiveness of the problem-solving tools in helping the team eight team characteristics studied. complete its assigned tack. Only tools used by the CPI team were Team leaders and other team members appeared more rated. A scale of 0 to 4 was used to report the toois' effectiveness comfortable with the CPI team process once they began the Exhibit 4. Tool effectiveness rating system team leader knowledge promotes tool use, and that when tools are easy to enderstand and use, the team will more readily adopt them. Fishbone diagrams were also familiar to team leaders and used by a large percentage of the teams. Again, this tool is easy to understand and use. Fishbone diagrams were commonly used to help identify problems with existing operations after initial use of the facility layout diagram and work flow analysis tools. Some tools that were not well known by team leaders were reported to be effective in supporting the team. Information flow diagrams, while familiar to only 31% of the team leaders and used by only 25% of the teams, received a score of 3.3 (of 4.0 ) for effectiveness. We hypothesize that the information flow diagram analysis of the current work processes (Exhibit 1). A common is an effective tool when used appropriately. As the trend toward approach for the teams was to use the facility layout diagram to increased information management technology continues, tools scope the project. Using existing documents or developing one like the information flow diagram may see increasing use. from scratch did not appear to impact this tool's effectiveness. Similarly, the difficulty-impact grid, familiar to only 6% of the Often, use of an existing layout was disrupted when errors were team leaders and used by 88% of the tearm, received a score of found. Maintaining accurate layouts is not a high priority in all 2.9 (of 4.0) for effectiveness. Again we can bypothesize that ease organizations. Work flow analysis was also effective in the carly of understanding and use contributes to a tool's acceptance by the stage of team operasions. It is interesting to note that both the team. facility layout diagram and the work flow analysis were familiar Some tools were familiar to team leaders, but were not found to many of the team leaders, were used by a large percentage of to be effective in supporting CPI teams. These include FMEA. the teams, and were found to be very effective in supporting the SPC, and FTA. If we accept the hypothesis that ease of teams' efforts to complete their task. We can hypothesize that understanding and use increase the probability that a tool will be Exhibit 5. Reported effectiveness of problem-solving toois by CPI team leaders used by a CPI team, then the limited use of these tools is logical. Team leader familiarity with problem-selviag wols was a In general, these tools require more time and experience to use good predictor of tool use and effectiveness. Also, problemeffectively. For example, you can use a draft facility layout solving tools that were casy to understand and apply were used diagram as an aid in problem solving, but you will not have the mere frequently and reported to be more effective in supporting same success with a draft FMEA. completico of the team task. One area of concern for us is the lack of understanding and Finally, some tools were not commonly used by CPI teams use of time studies. Only 13\% of team leaders had an because of the time required to irain team members in their use or understanding of time stedies, although 38% of the teams used to correctly apply them. If the organization had used some of the them in their analysis. The time studies completed by the teams mere complicated tools previously, then data from these previous were not couplod with a methods analysis study or used to develop applications were used by some teams, bot this was grnerally sot time standards. We were concerned about time studies bocause a critical factor in team operations. 12 of the 16 teams were working in facilities that had some form Of note was the lack of daca accuracy in organirations with of production control system, such as an MRP, MRPII, or ERR, in regard to time standards for production tasis and layout and routing place. These systems used time standards to support schedale documents. The issue of time standards accuracy is of particular and eapacity analysis. For all but 2 of the 12 teams, the time concern, because these standards are used as as esseatial databuse standards used were based on heuristics and were not engineered for MRP, MRPII, and ER.P systems. The accuracy problems standards. As expected, significant variances between planned regarding layouts and rowting documents are of lesser concem to and actual production rates and capacities were common in these CPI team operations, since the teams tended to re-create these at facilities. the beginaing of team operatioas to belp familiarine themselves Conclusions with the process under study. The CPI teams used in this study were uniqae: they focused their process improvement efforts on specific manufacturing problems that could be easily identified, and they were allowed to operate for only 1 week. This approach was used to edocate the organization on the use of CPI teams. It was hoped that a successful CPI team activity would provide a model for further CPI activities in the organization. Use of a CPI team was found to be an effective method for making improvements in manufacturing operations. It should be noted that CPI teani results may not yield the type of fundamental long-term improvements needed if company management is not committed to CPI (Tippett and Westbrook, 1995). CPI teams were cffective in solving production floor problems rapidly, although team performance was highly variable. To improve team performance, team leaders with a traditional enginecring background need to be aware of the differences between CPI and project teams. Differences in task scope and task completion time affect many team characteristics, such as team roles and processes. The fact that CPI teams strive to improve, rather than optimize, an operation sets them apart from project teams a) What is the significance of the paper

b) What you have learned from the paper

c) Any suggestions for improvement

d) Next steps

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started