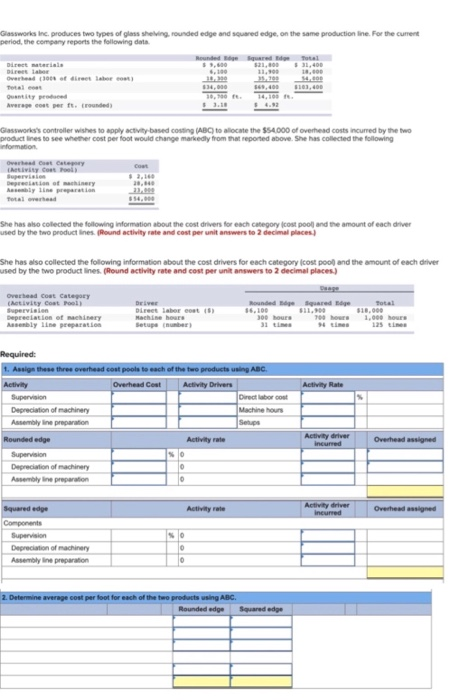

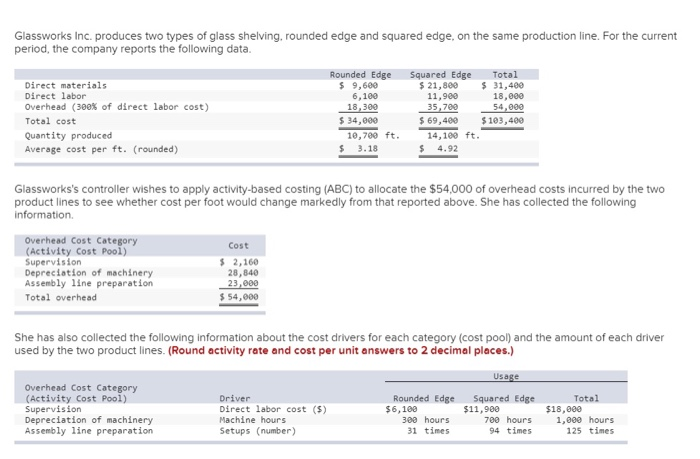

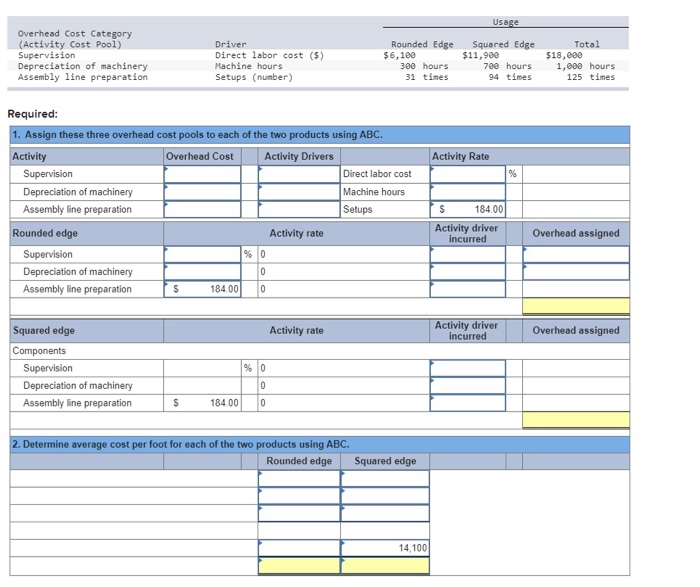

Glassworks Inc. produces two types of glass shelving, rounded edge and scared edge, on the same production line. For the current period, the company reports the following data Over 1000 of direct labe ) Quantity pod Average cost per t rouded Glassworks's controller wishes to apply activity based costing (ABC) to allocate the $54000 of overhead costs incurred by the two product lines to see whether cost per foot would change markedly from that reported above. She has collected the following formation Overhead Cat Category Depreciation of machinery Ansely line preparation Total head She has also collected the following information about the cost drivers for each category cost pool and the amount of each driver used by the two product lines. Round activity rate and cost per unit answers to 2 decimal places) She has also collected the following information about the cost drivers for each category cost pool and the amount of each driver used by the two product lines. (Round activity rate and cost per unit answers to 2 decimal places) Overhead coat Category Activity Coat Pool) Rounded 16.100 ht) quared $11.90 e Total 18.000 Deprecation of machinery Assembly in preparation Setupe number Activity Rate Required: 1. Assign these three overhead cost pools to each of the two products using ABC. Activity Overhead Cost Activity Drivers Supervision Director Depreciation of machinery Machines Assembly in preparation S Rounded edge Activity rate Supervision Depreciation of machinery Assembly in preparation Squared edge Overhead assigned Components Supervision Depreciation of machinery Assembly in preparation 2. Determine average cost perfoot for each of the two products using ABC. Rounded edge Squared edge Glassworks Inc. produces two types of glass shelving, rounded edge and squared edge, on the same production line. For the current period, the company reports the following data. Direct materials Direct labor Overhead (300% of direct labor cost) Total cost Quantity produced Average cost per ft. (rounded) Rounded Edge $ 9,600 6,100 18,300 $ 34,000 10,700 ft. $ 3.18 Squared Edge Total $ 21,880 $ 31,400 11,900 18.000 35,700 54,000 $ 69,400 $ 103,400 14,100 ft. $ 4.92 Glassworks's controller wishes to apply activity-based costing (ABC) to allocate the $54,000 of overhead costs incurred by the two product lines to see whether cost per foot would change markedly from that reported above. She has collected the following information Overhead Cost Category (Activity Cost Pool) Supervision Depreciation of machinery Assembly line preparation Total overhead Cost $ 2,160 28,840 23,000 $ 54,000 She has also collected the following information about the cost drivers for each category (cost pool) and the amount of each driver used by the two product lines. (Round activity rate and cost per unit answers to 2 decimal places.) Usage Overhead Cost Category (Activity Cost Pool) Supervision Depreciation of machinery Assembly line preparation Driver Direct labor cost (5) Machine hours Setups (number) Rounded Edge $6,100 300 hours 31 times Squared Edge $11,900 700 hours 94 times Total $18,000 1,000 hours 125 times Usage Overhead Cost Category (Activity Cost Pool) Supervision Depreciation of machinery Assembly line preparation Driver Direct labor cost (5) Machine hours Setups (number) Rounded Edge $6.100 300 hours 31 times Squared Edge Total $11,900 $18,000 780 hours1,000 hours 94 times 125 times Required: 1. Assign these three overhead cost pools to each of the two products using ABC. Overhead Cost Activity Drivers Activity Rate Activity Supervision Depreciation of machinery Assembly line preparation Direct labor cost Machine hours Setups $ 184.00 Rounded edge Activity rate Activity driver incurred Overhead assigned Supervision Depreciation of machinery Assembly line preparation PS 184.000 Squared edge Activity rate Activity driver incurred Overhead assigned Components Supervision Depreciation of machinery Assembly line preparation $ 184.00 2. Determine average cost per foot for each of the two products using ABC. Rounded edge Squared edge 14,100