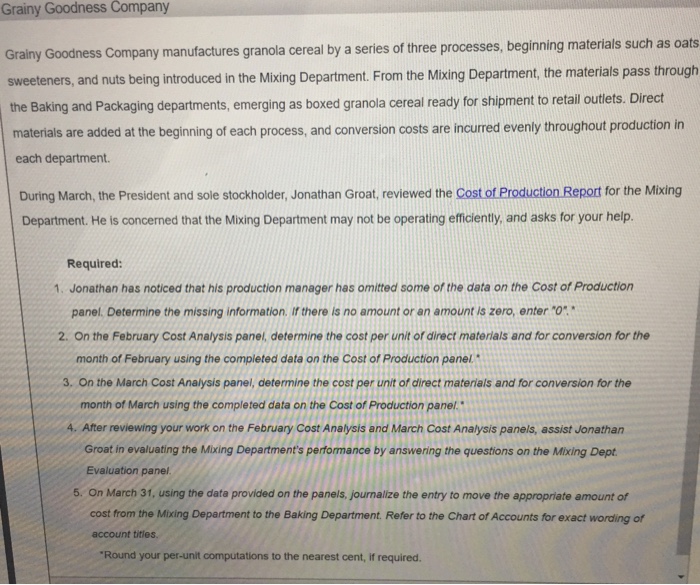

Grainy Goodness Company Grainy Goodness Company manufactures granola cereal by a series of three processes, beginning materials such as oats sweeteners, and nuts being introduced in the Mixing Department. From the Mixing Department, the materials pass through the Baking and Packaging departments, emerging as boxed granola cereal ready for shipment to retail outlets. Direct materials are added at the beginning of each process, and conversion costs are incurred evenly throughout production in each department During March, the President and sole stockholder, Jonathan Groat, reviewed the Cost of Production Report for the Mixing Department. He is concerned that the Mixing Department may not be operating efficienty, and asks for your help. Required: 1. Jonathan has noticed that his production manager has omitted some of the data on the Cost of Production panel. Determine the missing information, If there is no amount or an amount is zero, enter "o month of February using the completed data on the Cost of Production panel month of March using the completed data on the Cost of Production panel. 2. On the February Cost Analysis panel, determine the cost per unit of direct materials and for conversion for the 3. On the March Cost Analysis panel, determine the cost per unit of direct materials and for conversion for the 4. After reviewing your work on the February Cost Analysis and March Cost Analysis panels, assist Jonathan Groat in evaluating the Mixing Department's performance by answering the questions on the Mixing Dept Evaluation panel 5. On March 31, using the data provided on the panels, journalize the entry to move the appropriate amount of cost from the Mixing Department to the Baking Department. Refer to the Chart of Accounts for exact wording of account tities Round your per-unit computations to the nearest cent, if required. Grainy Goodness Company Grainy Goodness Company manufactures granola cereal by a series of three processes, beginning materials such as oats sweeteners, and nuts being introduced in the Mixing Department. From the Mixing Department, the materials pass through the Baking and Packaging departments, emerging as boxed granola cereal ready for shipment to retail outlets. Direct materials are added at the beginning of each process, and conversion costs are incurred evenly throughout production in each department During March, the President and sole stockholder, Jonathan Groat, reviewed the Cost of Production Report for the Mixing Department. He is concerned that the Mixing Department may not be operating efficienty, and asks for your help. Required: 1. Jonathan has noticed that his production manager has omitted some of the data on the Cost of Production panel. Determine the missing information, If there is no amount or an amount is zero, enter "o month of February using the completed data on the Cost of Production panel month of March using the completed data on the Cost of Production panel. 2. On the February Cost Analysis panel, determine the cost per unit of direct materials and for conversion for the 3. On the March Cost Analysis panel, determine the cost per unit of direct materials and for conversion for the 4. After reviewing your work on the February Cost Analysis and March Cost Analysis panels, assist Jonathan Groat in evaluating the Mixing Department's performance by answering the questions on the Mixing Dept Evaluation panel 5. On March 31, using the data provided on the panels, journalize the entry to move the appropriate amount of cost from the Mixing Department to the Baking Department. Refer to the Chart of Accounts for exact wording of account tities Round your per-unit computations to the nearest cent, if required