Answered step by step

Verified Expert Solution

Question

1 Approved Answer

hand calculation for energy of heater and reactor One method of preparing styrene is by the adiabatic dehydrogenation of ethylbenzene. But first, ethylbenzene is produced

hand calculation for energy of heater and reactor

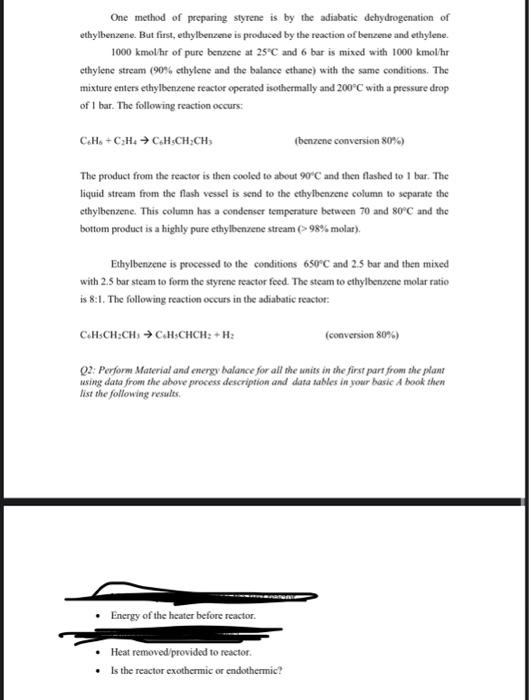

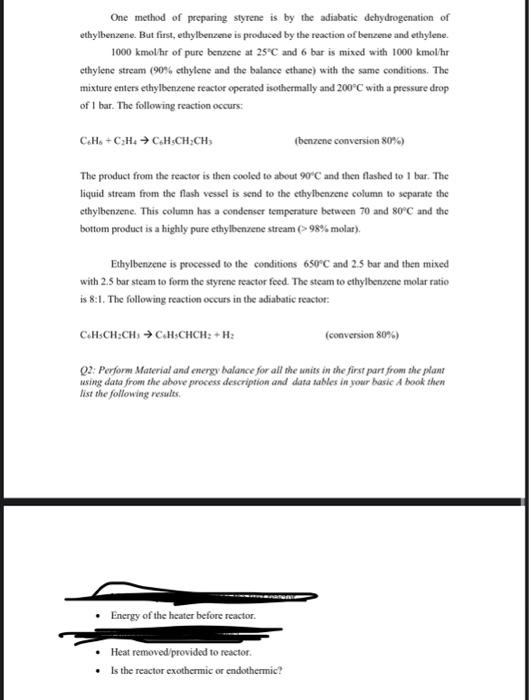

One method of preparing styrene is by the adiabatic dehydrogenation of ethylbenzene. But first, ethylbenzene is produced by the reaction of benzene and ethylene. 1000kmolhr of pure benzene at 25C and 6 bar is mixed with 1000kmolhr ethylene stream ( 90% ethylene and the balance ethane) with the same conditions. The mixture enters ethylbenzene reactor operated isothermally and 200C with a pressure drop of 1 bar. The following reaction occurs: C6H6+C2H4C6H3CH2CH3 (benzene conversion 80% ) The product from the reactor is then cooled to about 90C and then flashed to 1 bar. The liquid stream from the flash vessel is send to the ethylbenrene column to separate the ethylbenzene. This column has a condenser temperature between 70 and 80C and the bottom product is a highly pure ethylbenzene stream ( >98% molar). Ethylbenzene is processed to the conditions 650C and 2.5 bar and then mixed with 2.5 bar steam to form the styrene reactor foed. The steam to ethylbenzene molar ratio is 8:1. The following reaction occurs in the adiabatic reactor: C6H3CH2CH3C4H3CHCH2+H2 ( (conversion 80%) Q2: Perform Material and energy balance for all the units in the first part from the plamt using data from the above process description and data sables in your basic A book then list the following results. One method of preparing styrene is by the adiabatic dehydrogenation of ethylbenzene. But first, ethylbenzene is produced by the reaction of benzene and ethylene. 1000kmolhr of pure benzene at 25C and 6 bar is mixed with 1000kmolhr ethylene stream ( 90% ethylene and the balance ethane) with the same conditions. The mixture enters ethylbenzene reactor operated isothermally and 200C with a pressure drop of 1 bar. The following reaction occurs: C6H6+C2H4C6H3CH2CH3 (benzene conversion 80% ) The product from the reactor is then cooled to about 90C and then flashed to 1 bar. The liquid stream from the flash vessel is send to the ethylbenrene column to separate the ethylbenzene. This column has a condenser temperature between 70 and 80C and the bottom product is a highly pure ethylbenzene stream ( >98% molar). Ethylbenzene is processed to the conditions 650C and 2.5 bar and then mixed with 2.5 bar steam to form the styrene reactor foed. The steam to ethylbenzene molar ratio is 8:1. The following reaction occurs in the adiabatic reactor: C6H3CH2CH3C4H3CHCH2+H2 ( (conversion 80%) Q2: Perform Material and energy balance for all the units in the first part from the plamt using data from the above process description and data sables in your basic A book then list the following results

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started