Having difficulty in understanding this. Please thoroughly explain your result to all questions stated below. Will rate thumbs up:)

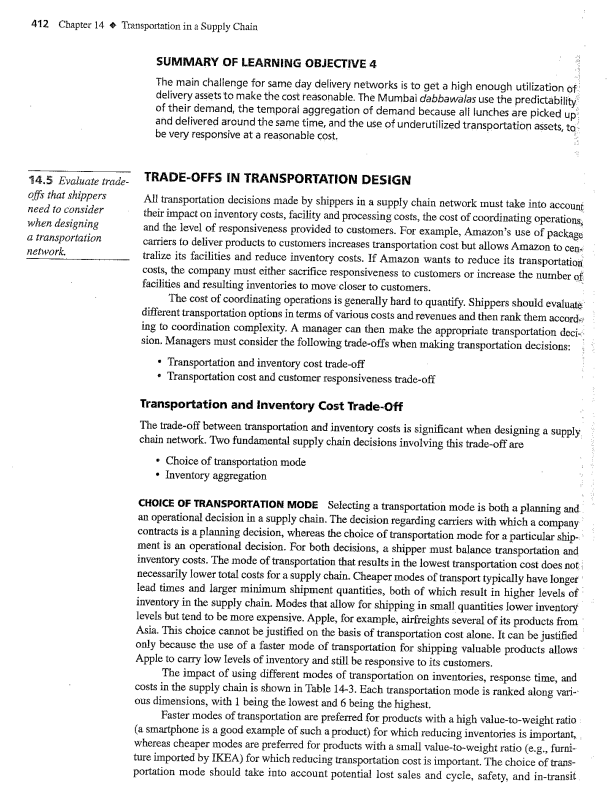

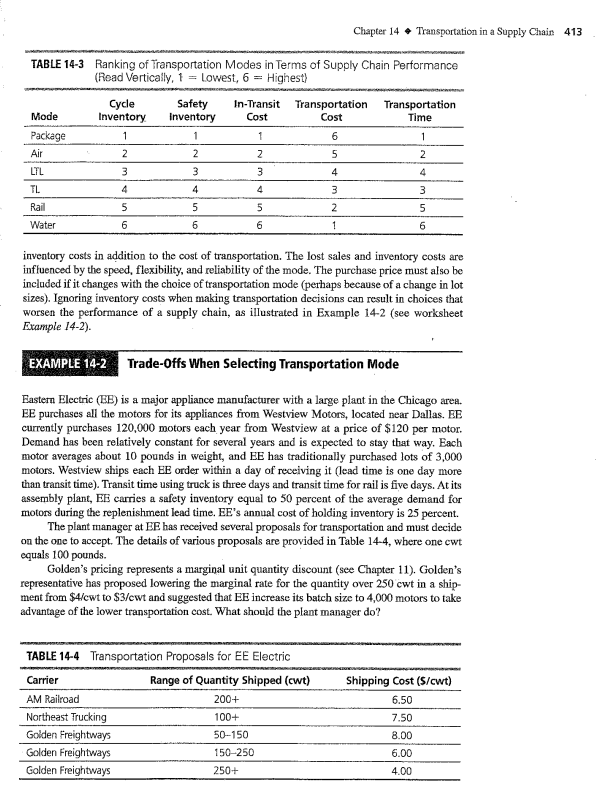

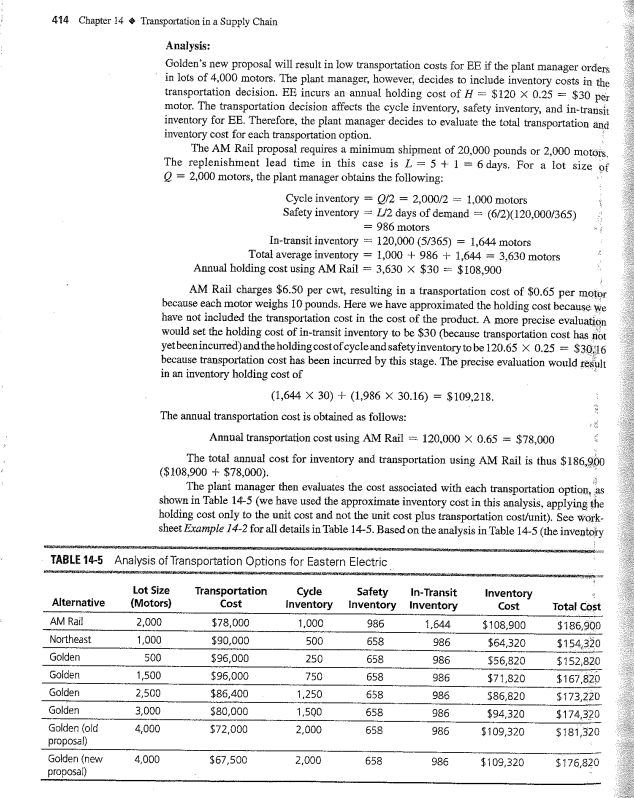

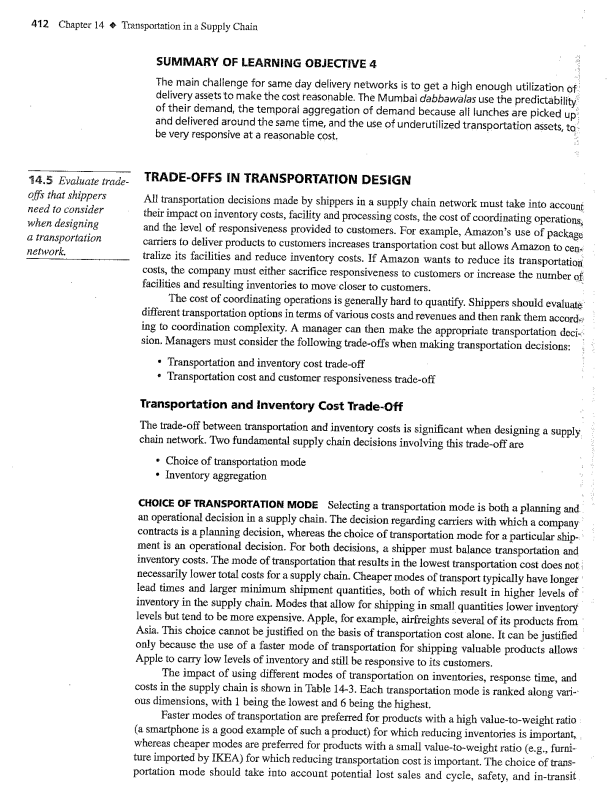

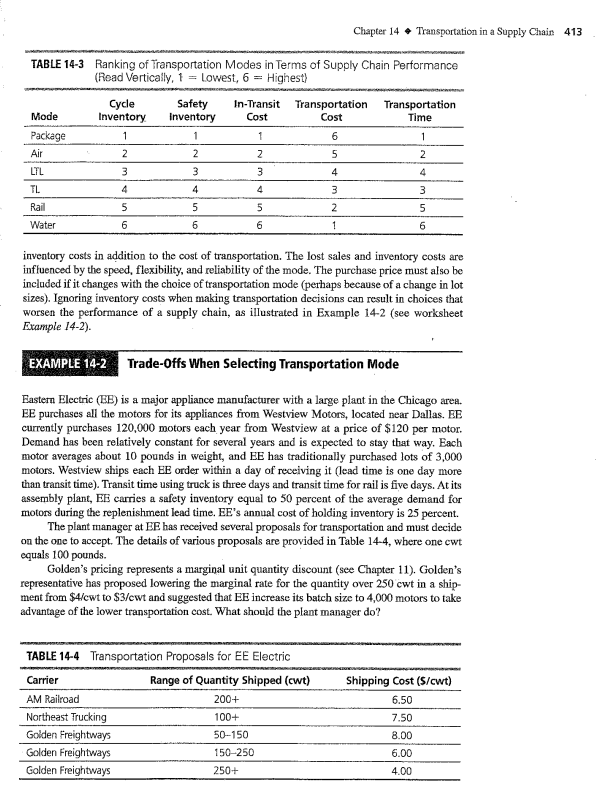

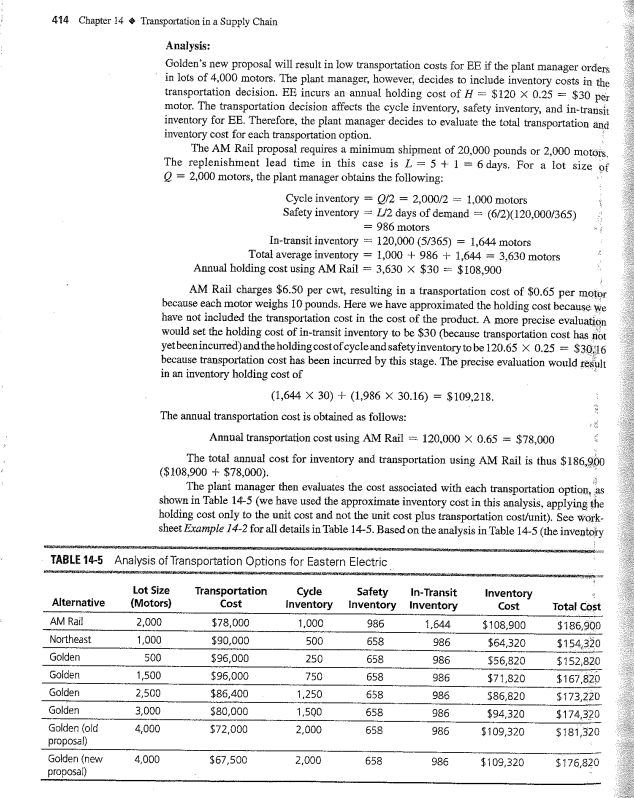

Read example 14-2 (pp. 413) from the textbook (picture below). The problem discusses how to select the mode of transportation based on cost. Cost elements include: transportation cost and cost of inventory. Cost of inventory includes: cost of holding cycle inventory, safety inventory and in-transit inventory. Review the Table 14-5 and the calculations for the AM Rail, 1st element in the Table. 14-5 page 414. (i) Recompute the total cost if the transit time is reduced to 2 days and the safety stock is set at 25% of average demand during the replenishment lead-time.. Comment on the cost associated with the in-transit inventory. (ii) Can you estimate the CSL form the data provided? Explain. (iii) Discuss the limitations of this approach? (iv) Can you combine the information provided in Table 14-3 with your cost model to select the best mode of transportation? Provide your comments. SUMMARY OF LEARNING OBJECTIVE 4 The main challenge for same day delivery networks is to get a high enough utilization of delivery assets to make the cost reasonable. The Mumbai dabbawalas use the predictability. of their demand, the temporai aggregation of demand because alf lunches are picked up: and delivered around the same time, and the use of underutilized transportation assets, to be very responsive at a reasonable cost. 14.5 Evaluate trade- TRADE-OFFS IN TRANSPORTATION DESIGN different transportation options in terms of various costs and revenues and then rank them accorder ing to coordination complexity. A manager can then make the appropriate transportation doci-: sion. Managers must consider the following trade-offs when making transportation decisions: - Transportation and inventory cost trade-off - Transportation cost and customer responsiveness trade-off Transportation and Inventory Cost Trade-Off The trade-off between transportation and inventory costs is significant when designing a supply: chain network. Two fundamental supply chain decisions involving this trade-off are - Choice of transpartation mode - Inventory aggregation CHOICE OF TRANSPORTATION MODE Selecting a transportation mode is both a planning and an operational decision in a supply chain. The decision regarding carriers with which a company contracts is a planning decision, whereas the choice of transportation mode for a particular shipment is an operational decision. For both decisions, a shipper must balance transportation and inventory costs. The mode of transportation that results in the lowest transportation cost does not necessarily lower total costs for a supply chain. Cheaper modes of transport typically have longer lead times and larger minimum shipment quantities, both of which result in higher levels of inventory in the supply chain. Modes that allow for shipping in small quantities lower inventory levels but tend to be more expensive. Apple, for example, airfreights several of its products from Asia. This choice cannot be justified on the basis of transportation cost alone. It can be justified only because the use of a faster mode of transportation for shipping valuable products allows Apple to carry low levels of inventory and still be responsive to its customers. The impact of using different modes of transportation on inventories, response time, and costs in the supply chain is shown in Table 14-3. Each transportation mode is ranked along various dimensions, with 1 being the lowest and 6 being the highest. Faster modes of transportation are preferred for products with a high value-to-weight ratio (a smartphone is a good example of such a product) for which reducing inventories is important, whereas cheaper modes are preferred for products with a small value-to-weight ratio (e.g., furniture imported by IKEA) for which reducing transportation cost is important. The choice of transportation mode should take into account potential lost sales and cycle, safety, and in-transit. Chapter 14 Transportation in a Supply Chais 413 TABLE 14-3 Ranking of Transportation Modes in Terms of Supply Chain Performance (Read Vertically, 1= Lowest, 6= Highest? inventory costs in addition to the cost of transportation. The lost sales and inventory costs are inffuenced by the speed, flexibility, and reliability of the mode. The purchase price must also be incladed if it changes with the choice of transportation mode (perhaps because of a change in lot sizes). Ignoring inventory costs when making transportation decisions can result in choices that worsen the performance of a supply chain, as illustrated in Example 14-2 (see worksheet Example 14-2). EXAMPLE 14-2 Trade-0ffs When Selecting Transportation Mode Eastera Electric (EB) is a major appliance manufacturer with a large plant in the Chicago area. EE purchases all the motors for its appliances from Westview Motors, located near Dallas. EE currently purchases 120,000 motors each year from Westview at a price of $120 per motor. Demand has been relatively constant for several years and is expected to stay that way. Each motor averages about 10 pounds in weight, and EE has traditionally purchased lots of 3,000 motors. Westview ships each EE order within a day of receiving it (lead time is one day more than transit time). Transit time using truck is three days and transit time for rail is five days. At its assembly plant, EE carries a safety inventory equal to 50 percent of the average demand for motors during the replenishment lead time. EE's annual cost of holding inventory is 25 percent. The plant manager at EE has received several proposals for transportation and must decide on the one to accept. The details of various proposals are provided in Table 14-4, where one cwt equals 100 pounds. Golden's pricing represents a marginal unit quantity discount (see Chapter 11). Golden's representative has proposed lowering the marginal rate for the quantity over 250cwt in a shipment from $4/ cwt to $3/ cwt and suggested that EE increase its batch size to 4,000 motors to take advantage of the lower transportation cost. What should the plant manager do? transportation decision. EE incurs an annual holding cost of H=$1200.25=$30 peir motor. The transportation decision affects the cycle inventory, safety inventory, and in-transit inventory for EE. Therefore, the plant manager decides to evaluate the total transportation and inventory cost for each transportation option. The AM Rail proposal requires a minimum shipment of 20,000 pounds or 2,000 motois. The replenishment lead time in this case is L=5+1=6 days. For a lot size of Q=2,000 motors, the plant manager obtains the following: Cycle inventory =Q/2=2,000/2=1,000 motors Safety inventory =L/2 days of demand =(6/2)(120,000/365) =986 motors In-transit inventory =120,000(5/365)=1,644 motors Total average inventory =1,000+986+1,644=3,630 motors Annual holding cost using AM Rail =3,630$30=$108,900 AM Rail charges $6.50 per cwt, resulting in a transportation cost of $0.65 per motor because each motor weighs 10 pounds. Here we have approximated the holding cost because we have not included the transportation cost in the cost of the product. A more precise evaluation would set the holding cost of in-transit inventory to be $30 (because transportation cost has not yet been incurred) and the holding cost of cycle and safetyinventory to be 120.650.25=$30.16 because transportation cost has been incurred by this stage. The precise evaluation would result in an inventory holding cost of (1,64430)+(1,98630.16)=$109,218. The annual transportation cost is obtained as follows: Annual transportation cost using AM Rail =120,0000.65=$78,000 The total annual cost for inventory and transportation using AM Rail is thus $186,900 ($108,900+$78,000). Read example 14-2 (pp. 413) from the textbook (picture below). The problem discusses how to select the mode of transportation based on cost. Cost elements include: transportation cost and cost of inventory. Cost of inventory includes: cost of holding cycle inventory, safety inventory and in-transit inventory. Review the Table 14-5 and the calculations for the AM Rail, 1st element in the Table. 14-5 page 414. (i) Recompute the total cost if the transit time is reduced to 2 days and the safety stock is set at 25% of average demand during the replenishment lead-time.. Comment on the cost associated with the in-transit inventory. (ii) Can you estimate the CSL form the data provided? Explain. (iii) Discuss the limitations of this approach? (iv) Can you combine the information provided in Table 14-3 with your cost model to select the best mode of transportation? Provide your comments. SUMMARY OF LEARNING OBJECTIVE 4 The main challenge for same day delivery networks is to get a high enough utilization of delivery assets to make the cost reasonable. The Mumbai dabbawalas use the predictability. of their demand, the temporai aggregation of demand because alf lunches are picked up: and delivered around the same time, and the use of underutilized transportation assets, to be very responsive at a reasonable cost. 14.5 Evaluate trade- TRADE-OFFS IN TRANSPORTATION DESIGN different transportation options in terms of various costs and revenues and then rank them accorder ing to coordination complexity. A manager can then make the appropriate transportation doci-: sion. Managers must consider the following trade-offs when making transportation decisions: - Transportation and inventory cost trade-off - Transportation cost and customer responsiveness trade-off Transportation and Inventory Cost Trade-Off The trade-off between transportation and inventory costs is significant when designing a supply: chain network. Two fundamental supply chain decisions involving this trade-off are - Choice of transpartation mode - Inventory aggregation CHOICE OF TRANSPORTATION MODE Selecting a transportation mode is both a planning and an operational decision in a supply chain. The decision regarding carriers with which a company contracts is a planning decision, whereas the choice of transportation mode for a particular shipment is an operational decision. For both decisions, a shipper must balance transportation and inventory costs. The mode of transportation that results in the lowest transportation cost does not necessarily lower total costs for a supply chain. Cheaper modes of transport typically have longer lead times and larger minimum shipment quantities, both of which result in higher levels of inventory in the supply chain. Modes that allow for shipping in small quantities lower inventory levels but tend to be more expensive. Apple, for example, airfreights several of its products from Asia. This choice cannot be justified on the basis of transportation cost alone. It can be justified only because the use of a faster mode of transportation for shipping valuable products allows Apple to carry low levels of inventory and still be responsive to its customers. The impact of using different modes of transportation on inventories, response time, and costs in the supply chain is shown in Table 14-3. Each transportation mode is ranked along various dimensions, with 1 being the lowest and 6 being the highest. Faster modes of transportation are preferred for products with a high value-to-weight ratio (a smartphone is a good example of such a product) for which reducing inventories is important, whereas cheaper modes are preferred for products with a small value-to-weight ratio (e.g., furniture imported by IKEA) for which reducing transportation cost is important. The choice of transportation mode should take into account potential lost sales and cycle, safety, and in-transit. Chapter 14 Transportation in a Supply Chais 413 TABLE 14-3 Ranking of Transportation Modes in Terms of Supply Chain Performance (Read Vertically, 1= Lowest, 6= Highest? inventory costs in addition to the cost of transportation. The lost sales and inventory costs are inffuenced by the speed, flexibility, and reliability of the mode. The purchase price must also be incladed if it changes with the choice of transportation mode (perhaps because of a change in lot sizes). Ignoring inventory costs when making transportation decisions can result in choices that worsen the performance of a supply chain, as illustrated in Example 14-2 (see worksheet Example 14-2). EXAMPLE 14-2 Trade-0ffs When Selecting Transportation Mode Eastera Electric (EB) is a major appliance manufacturer with a large plant in the Chicago area. EE purchases all the motors for its appliances from Westview Motors, located near Dallas. EE currently purchases 120,000 motors each year from Westview at a price of $120 per motor. Demand has been relatively constant for several years and is expected to stay that way. Each motor averages about 10 pounds in weight, and EE has traditionally purchased lots of 3,000 motors. Westview ships each EE order within a day of receiving it (lead time is one day more than transit time). Transit time using truck is three days and transit time for rail is five days. At its assembly plant, EE carries a safety inventory equal to 50 percent of the average demand for motors during the replenishment lead time. EE's annual cost of holding inventory is 25 percent. The plant manager at EE has received several proposals for transportation and must decide on the one to accept. The details of various proposals are provided in Table 14-4, where one cwt equals 100 pounds. Golden's pricing represents a marginal unit quantity discount (see Chapter 11). Golden's representative has proposed lowering the marginal rate for the quantity over 250cwt in a shipment from $4/ cwt to $3/ cwt and suggested that EE increase its batch size to 4,000 motors to take advantage of the lower transportation cost. What should the plant manager do? transportation decision. EE incurs an annual holding cost of H=$1200.25=$30 peir motor. The transportation decision affects the cycle inventory, safety inventory, and in-transit inventory for EE. Therefore, the plant manager decides to evaluate the total transportation and inventory cost for each transportation option. The AM Rail proposal requires a minimum shipment of 20,000 pounds or 2,000 motois. The replenishment lead time in this case is L=5+1=6 days. For a lot size of Q=2,000 motors, the plant manager obtains the following: Cycle inventory =Q/2=2,000/2=1,000 motors Safety inventory =L/2 days of demand =(6/2)(120,000/365) =986 motors In-transit inventory =120,000(5/365)=1,644 motors Total average inventory =1,000+986+1,644=3,630 motors Annual holding cost using AM Rail =3,630$30=$108,900 AM Rail charges $6.50 per cwt, resulting in a transportation cost of $0.65 per motor because each motor weighs 10 pounds. Here we have approximated the holding cost because we have not included the transportation cost in the cost of the product. A more precise evaluation would set the holding cost of in-transit inventory to be $30 (because transportation cost has not yet been incurred) and the holding cost of cycle and safetyinventory to be 120.650.25=$30.16 because transportation cost has been incurred by this stage. The precise evaluation would result in an inventory holding cost of (1,64430)+(1,98630.16)=$109,218. The annual transportation cost is obtained as follows: Annual transportation cost using AM Rail =120,0000.65=$78,000 The total annual cost for inventory and transportation using AM Rail is thus $186,900 ($108,900+$78,000)