Question

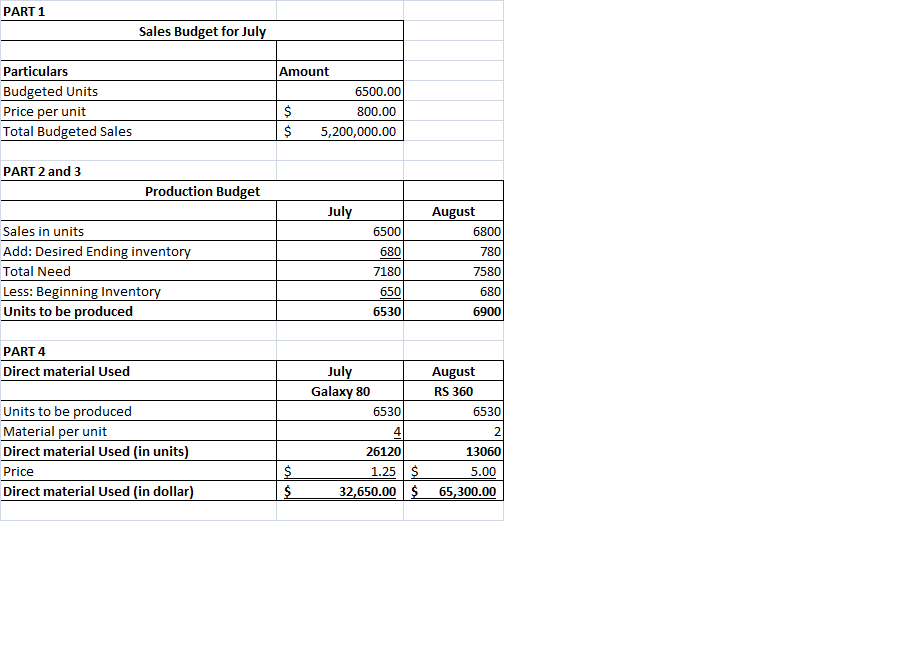

Hawkins Engineerings management wants to prepare budgets for one of its products, GalaxyRS, for July 2019. The firm sells the product for $800 per unit

Hawkins Engineerings management wants to prepare budgets for one of its products, GalaxyRS, for July 2019. The firm sells the product for $800 per unit and has the following expected sales (in units) for these months in 2019:

April May June July August September

6,000 4,000 5,600 6,500 6,800 7,800

Typically, cash sales for Hawkins represent 20% of sales while credit sales represent 80%. Hawkins bills customers on the first day of the month following the month of sale. Experience has shown that 85% of the companys billings will be collected during the month of sale, 10% by the end of the month after the sale and 5% will ultimately be uncollectible.

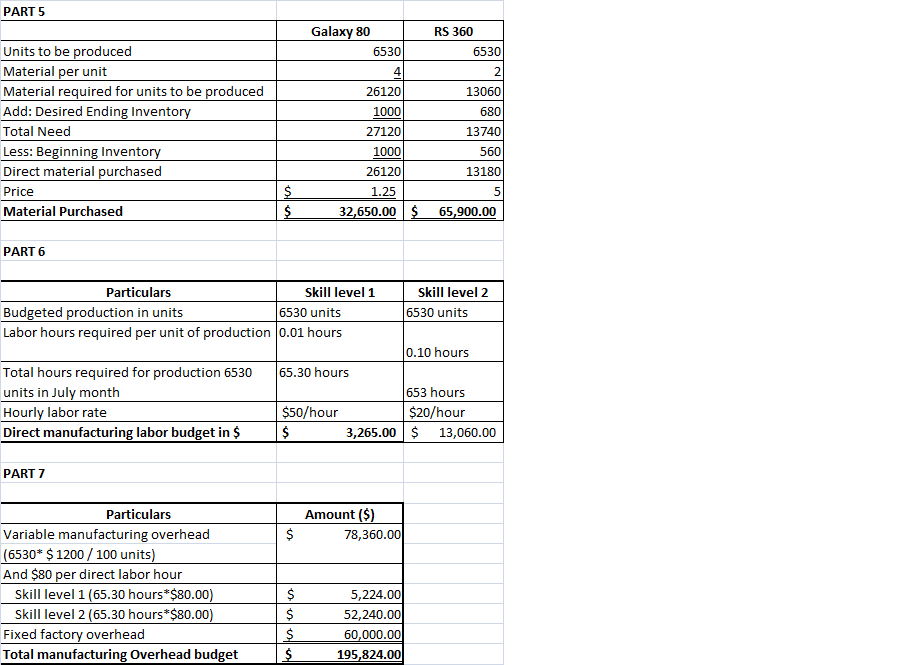

The production process requires the following:

Standard Costs:

Galaxy-80 4 lbs $1.25/lb

RS-360 2 lbs $5.00/lb

Direct labor

Skill level 1 0.01 hours $50/hour

Skill level 2 0.10 hours $20/hour

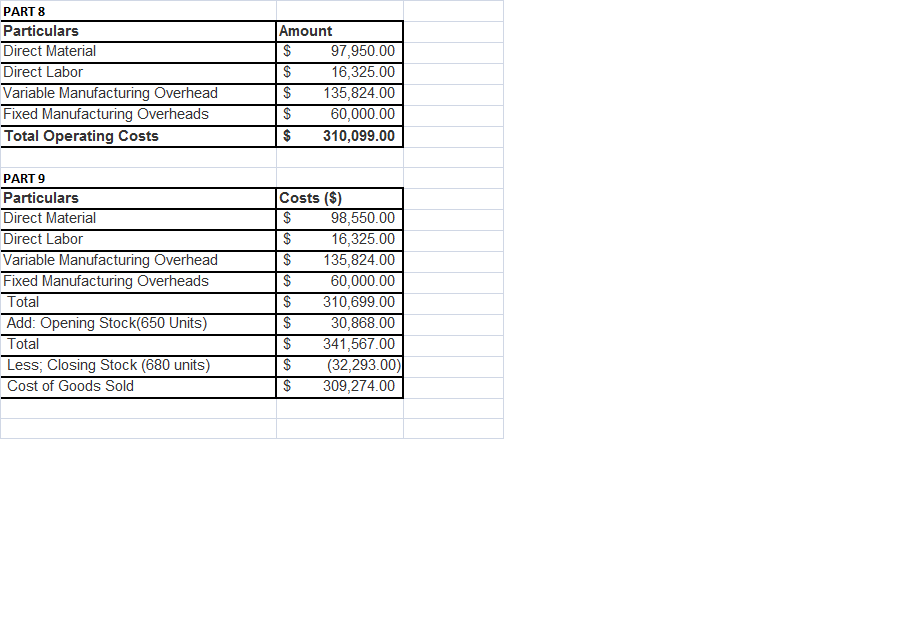

Variable manufacturing overhead is budgeted at $1,200 per batch (of 100 units) plus $80 per direct labor hour. In addition to variable overhead, the firm has a monthly fixed factory overhead of $60,000, of which $25,000 is depreciation expense. The firm pays all manufacturing labor and factory overhead when incurred.

The firms policy is to maintain an ending finished goods inventory each month equal to 10% of the following months budgeted sales, but in no case less than 500 units. All materials inventories are to be maintained at 5% of the production needs for the next month, but not to exceed 1,000 pounds. The firm expects all inventories at the end of June to be within the guidelines.

The purchase terms for materials are 3/10, n/30. Hawkings makes all payments within the discount period. Experience has shown that 80% of the purchases are paid in the month of the purchase and the remainder are paid in the month immediately following. In June 2019, the firm budgeted purchases of $30,000 for Galaxy-80 and $20,000 for RS-360.

Total budgeted marketing, distribution, customer service and administrative costs for 2019 are 1,850,000. Of this amount, $1,200,000 is considered fixed and includes depreciation expense of $150,000. The remainder varies with sales. The budgeted total sales for 2019 are $4 million. All marketing and administrative costs are paid in the month incurred.

Additional information follows:

Cash balance $40,000

Management desires to maintain an end-of-month minimum cash balance of $40,000. The firm has an agreement with a local bank to borrow its short-term needs in multiples of $1,000 up to $100,000 at an annual interest rate of 12%. Borrowings are assumed to occur at the end of the month. Bank borrowing at July 1 is $0.

Required:

On the basis of the preceding data and projections, prepare the following budgets:

- Budgeted income statement for July

- Cash budget for July

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started