Question

He wondered if he used optimum inventory practises. EPM had already established its company operations, in my opinion is the proper moment we should evaluate

He wondered if he used optimum inventory practises. EPM had already established its company operations, in my opinion is the proper moment we should evaluate the inventory procedures of EPM, Mr. Tim said Ms. Mary the Eyewear Consultant. We also should evaluate on the efficiency and efficacy of the inventory system using the Point of Sales System (POS), Mr. Tim added. Yes, Mr. Tim, I agree with you boss, Ms. Mary replied. Inventory practises should be evaluated in these areas:

1. Inventory recording of eyeglass items, including value determination;

2. Inventory plan (holding level, reorder level, and safety stock);

3. Inventory software system to maintain inventory levels; and

4. Safety precautions, including company's physical inventory count methods.

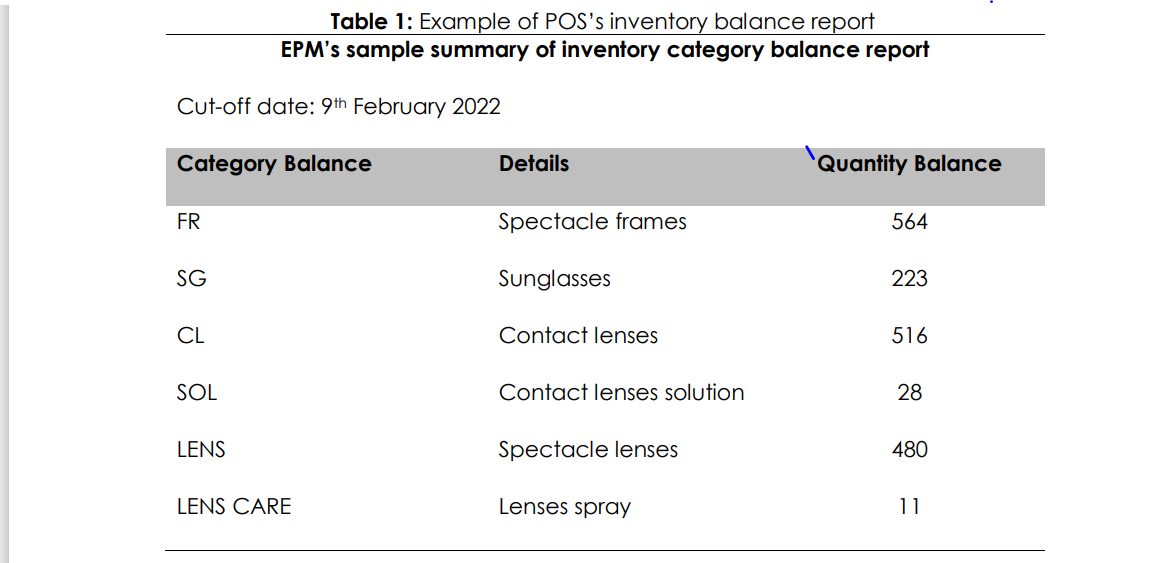

EPM must maintain a balanced inventory to stay competitive. Overstocking can hurt a company's cashflow, while understocking can drive customers away. Mr. Tim also knows that inventory management affects profit. Mr. Tim wants to implement the best inventory system to prevent improper inventory management from hurting the company's finances. Identification EPM keeps the most frames, sunglasses, lenses, and contacts. The company also stocks contact lens solutions and sprays. Brands are used to code inventories. The head office sells most eyeglasses, including frames, sunglasses, lenses, and contacts. Direct-ordered contact lenses Inventory is documented at the head office or supplier pricing and paid within 30 days of credit term. Mr. Tim visits the head office every month to choose high-end eyewear, but for other eyewear, he browses the database and orders online. EPM doesn't sell consignments. EPM inventories include eyewear purchased. In the POS, they'll enter product brands, descriptions, quantities, and values. The invoice from the vendor (head office or other suppliers) will be manually coded into POS as "stock-in" for each eyeglass product. POS is not linked to purchase order. According to accounting standards, the invoice price is inventory at cost. Customers pay a fair markup for this inventory. The POS generates a "stock-out" sales bill for eyewear transactions. This method shows inventory balance immediately. Before entering POS, the Manager approves all paperwork. Table 1 demonstrates an eyeglass inventory balance report based on POS cut-off dates. Table 1: Example of POSs inventory balance report EPMs sample summary of inventory category balance report Cut-off date: 9th February 2022

For the wrong items received, damaged or faulty eyewear products should be returned to the vendor (head office or other supplier) within the warranty period. Returning eyewear products to vendor is to cancel the purchase permanently due to wrong items received or to request for item replacement for correct and good condition eyewear products. Any outgoing eyewear products returned to vendor should be recorded as stock-out in POS with supported credit note given by the vendor. The new delivery for replaced item will be recorded as new purchase transactions in POS based on the invoice provided by the vendor. This way the inventory balance stated in the system will tally with the physical inventory balance at EPM premise.For the wrong items received, damaged or faulty eyewear products should be returned to the vendor (head office or other supplier) within the warranty period. Returning eyewear products to vendor is to cancel the purchase permanently due to wrong items received or to request for item replacement for correct and good condition eyewear products. Any outgoing eyewear products returned to vendor should be recorded as stock-out in POS with supported credit note given by the vendor. The new delivery for replaced item will be recorded as new purchase transactions in POS based on the invoice provided by the vendor. This way the inventory balance stated in the system will tally with the physical inventory balance at EPM premise.For the wrong items received, damaged or faulty eyewear products should be returned to the vendor (head office or other supplier) within the warranty period. Returning eyewear products to vendor is to cancel the purchase permanently due to wrong items received or to request for item replacement for correct and good condition eyewear products. Any outgoing eyewear products returned to vendor should be recorded as stock-out in POS with supported credit note given by the vendor. The new delivery for replaced item will be recorded as new purchase transactions in POS based on the invoice provided by the vendor. This way the inventory balance stated in the system will tally with the physical inventory balance at EPM premise.Return damaged or faulty eyewear to the vendor (head office or other source) within the warranty period for erroneous items received. Returning eyewear to the vendor cancels the purchase or requests a replacement for proper and good-condition items. POS should stock-out returned eyewear with vendor credit note. POS will record new purchase transactions for replaced items based on vendor invoices. Hence, the system's inventory balance will match EPM's.

Inventory Aging

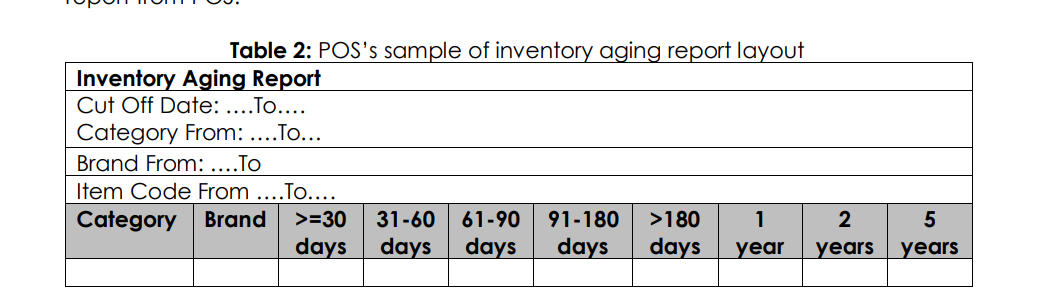

The POS generates a stock ageing report for sunglasses and glasses. After buying merchandise at a discount, EPM usually sells it all within two years. Sunglasses and sight frames have no obsolete inventory, hence there is no write-off inventory value after one year. Inventory stays at cost, not net realisable value. Table 2 shows the POS inventory ageing report sample.

Table 2: POSs sample of inventory aging report layout

Next, external suppliers will replace unsold contact lenses of 16-month expiry date with new ones. The expired contact lenses will be returned to the suppliers with credit note provided by the suppliers. The credit note will then be keyed into POS as outgoing (stock-out) to reduce the inventory balance while the replaced contact lenses will be keyed into POS as incoming (stock-in) inventory based on the invoices provided by the suppliers. Meanwhile, spectacle lenses do not have expiry date

Inventory Safety Measures

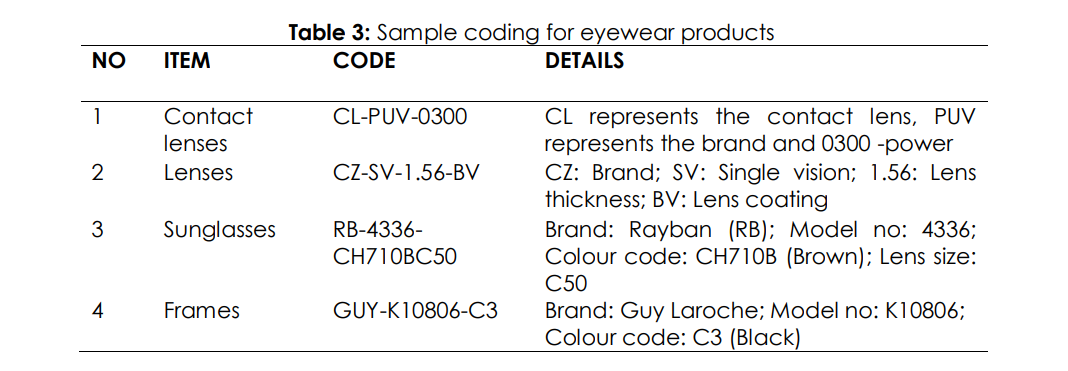

EPM displays their branded eyewear in lockable glass showcases. Instead, low-end spectacle frames are displayed on open shelving cabinets along the walkway for clients to try on. The employees will watch open shelves while clients try out products. The shop corner also has a security camera. Showcase glass cases with locks near the cashier desk hold boxed contact lenses. The cashier counter cabinets usually hold the lenses. Then, EPM workers manually code serial numbers into POS to identify eyewear products. Table 3 shows how brands and eyewear features are coded.

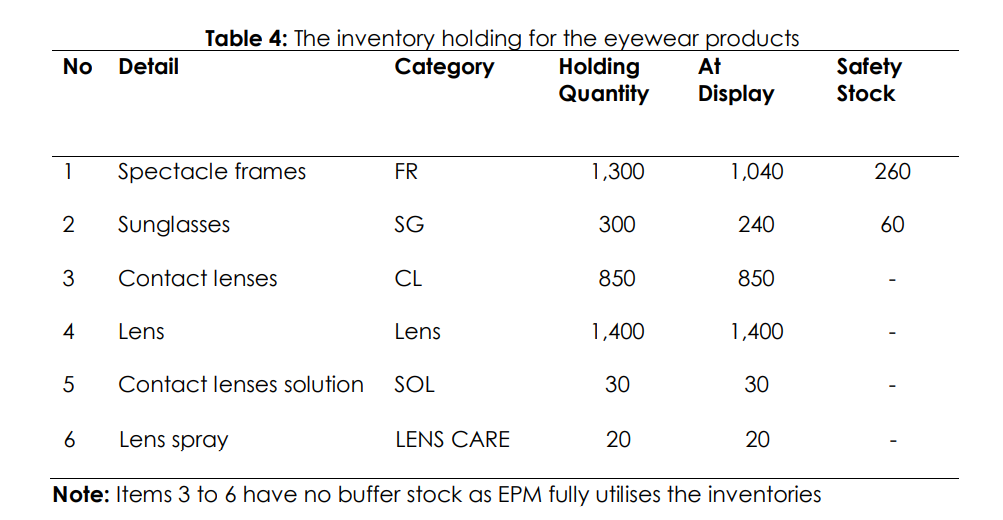

The Inventory Plan Holding Level The holding level eyewear products at EPM are based on historical sales data derived from 80-20 rule. The inventory concept is to display 80% of the total merchandise for customers easy accessible while the remaining 20% is kept as buffer stock or also known as safety stock. In this case, Mr Tim runs through the inventory holding level on monthly basis particularly during the second or third week of the month. If the inventory level falls below the holding level, Mr Tim will proceed for ordering the respective eyewear products so that new inventory products will be received by end of the month. For example, if the spectacle frames inventory balance is 800 (holding level quantity 1,300) by second or third week, Mr Tim should place order for 500 spectacle frames by end of the month. Table 4 shows the details of inventory holding for the eyewear products.

Table 4: The inventory holding for the eyewear products

Note: Items 3 to 6 have no buffer stock as EPM fully utilises the inventories EPM is relatively more concern with the value (RM) rather the volume of inventories. The item categories for branded eyewear products with significantly high values automatically fall under low-volume inventory balance for an effective control of low-inventory and the cost. Therefore, the inventory holding pattern negatively correlates with the value and volume of EPMs eyewear products. For example, high value branded eyewear products will have low-volume inventory level while low[1]value ordinary brands will have high-volume inventory level as they have higher demand from customers. This is the current inventory practices at EPM to manage the inventory based on product categories. Table 5 presents the examples of branded and ordinary brand eyewear products at EPM.

Table 5: The branded and ordinary brand eyewear products

| No | Product | Branded | Ordinary Brand |

| 1 | Spectacle frames and sunglasses | Rayban, Bonia, Oakley and French Connection | Polo exchange, KVE and Aviator |

| 2 | Contact lenses | Biofinity, Air-Optix, Acuvue and Medic Soft | Fresh Kon and ProVision |

| 3 | Lenses | Hoya and Carl Zeiss | Platinum, HD Pro and Medic care

|

Reorder Level

EPM orders inventory monthly based on purchase histories and sales cycles, which vary each eyewear product. Mr. Tim does not use any precise methods to determine the eyewear reorder level. EPM orders monthly stocks based on sales cycles throughout peak and non-peak seasons. Depending on monthly purchase activity, the best reorder level is every second or third week. The prefix inventory level is always the leftover quantity plus the new reorder quantity. Monthly buying activity affects reorder quantity. Holding level remains fixed until management adjusts it depending on demand pattern or sales cycle.

Physical Inventory Count

EPM counts its inventory twice a year, in March and September, on weekdays. The branches follow the main office's physical inventory count instructions and are audited annually by the 2 Audit Officers. The head office manages branch inventory counts. EPM notifies head office and external auditor of the physical inventory count date.

To simplify inventory counts and eliminate discrepancies, vendor invoices will be entered into POS. The head office will then advise each outlet to conduct an internal inventory count before making any inventory adjustments to reconcile the physical and system inventory balances. Two or three days before the physical inventory count, do this. Checking and rectifying disparities between physical and system inventory balances, such as owing to input errors or late invoicing, must be done immediately. Any eyeglasses product disparity should be notified to head office and the workers concerned should compensate for the inventory loss.

QUESTIONS

1. Solve the EOQ & POQ of this Case

2. Find the Safety Stock and reorder point

3. Develop the MRP table using this case study

Pls attach the calculations methods

I need this urgently please help me

At least solve one of the problem

Table 1: Example of POS's inventory balance report EPM's sample summary of inventory category balance report Cut-off date: 9th February 2022 \begin{tabular}{llc} Category Balance & Details & 'Quantity Balance \\ FR & Spectacle frames & 564 \\ SG & Sunglasses & 223 \\ CL & Contactlenses & 516 \\ SOL & Contactlenses solution & 28 \\ LENS & Spectacle lenses & 480 \\ LENS CARE & Lenses spray & 11 \\ \hline \end{tabular} Table 2: POS's sample of inventory aging report layout Table 3: Sample coding for eyewear products Note: Items 3 to 6 have no buffer stock as EPM fully utilises the inventoriesStep by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started