Hello, I'm currently in a Managerial economics MBA course and Case 6.3 -- Rescuing Nissan is really over my head. I tried the first problem but am not sure I am on the right track with the calculation.

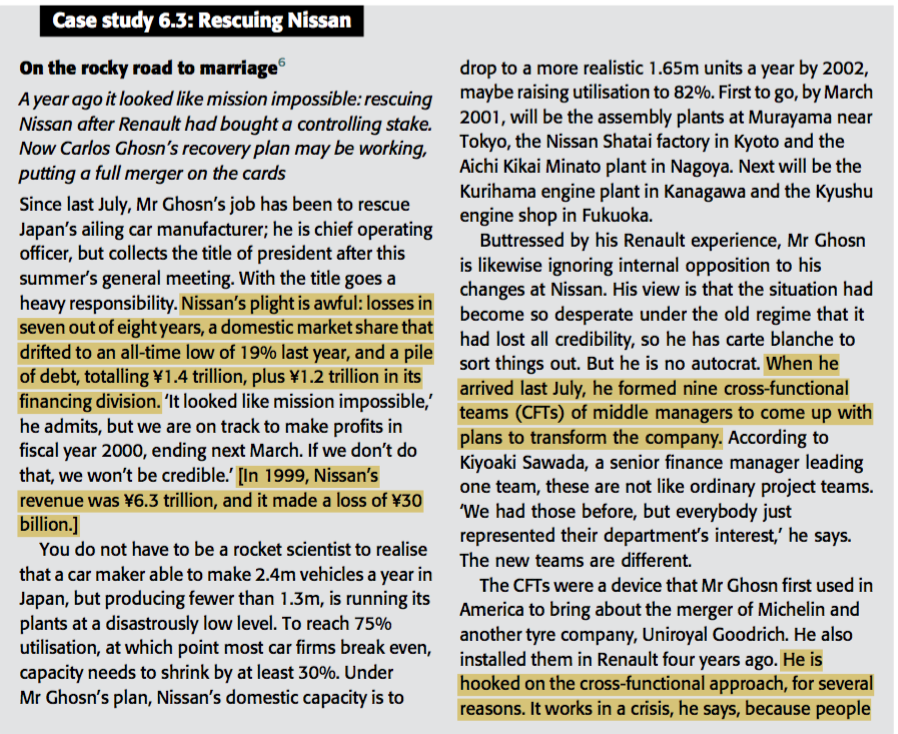

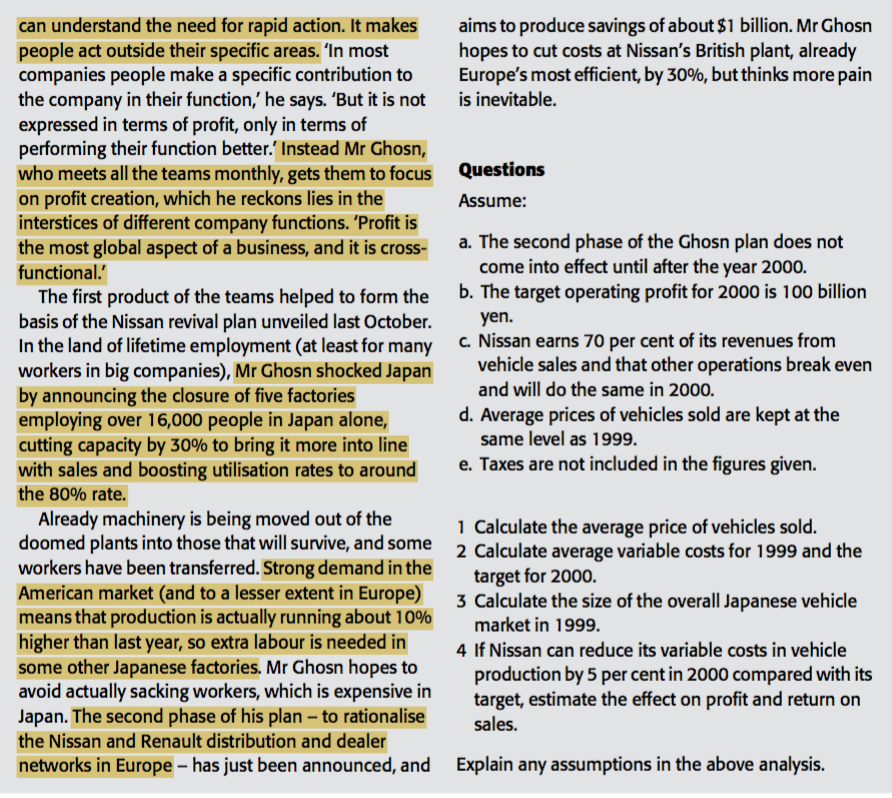

Case study 6.3: Rescuing Nissan On the rocky road to marriage drop to a more realistic 1.65m units a year by 2002, A year ago it looked like mission impossible: rescuing maybe raising utilisation to 82%. First to go, by March Nissan after Renault had bought a controlling stake. 2001, will be the assembly plants at Murayama near Now Carlos Ghosn's recovery plan may be working, Tokyo, the Nissan Shatai factory in Kyoto and the putting a full merger on the cards Aichi Kikai Minato plant in Nagoya. Next will be the Since last July, Mr Ghosn's job has been to rescue Kurihama engine plant in Kanagawa and the Kyushu Japan's ailing car manufacturer; he is chief operating engine shop in Fukuoka. officer, but collects the title of president after this Buttressed by his Renault experience, Mr Ghosn summer's general meeting. With the title goes a is likewise ignoring internal opposition to his heavy responsibility. Nissan's plight is awful: losses in changes at Nissan. His view is that the situation had seven out of eight years, a domestic market share that become so desperate under the old regime that it drifted to an all-time low of 19% last year, and a pile had lost all credibility, so he has carte blanche to of debt, totalling *1.4 trillion, plus *1.2 trillion in its sort things out. But he is no autocrat. When he financing division. 'It looked like mission impossible,' arrived last July, he formed nine cross-functional he admits, but we are on track to make profits in teams (CFTs) of middle managers to come up with fiscal year 2000, ending next March. If we don't do plans to transform the company. According to that, we won't be credible.' [In 1999, Nissan's Kiyoaki Sawada, a senior finance manager leading revenue was v6.3 trillion, and it made a loss of v30 one team, these are not like ordinary project teams. billion.] 'We had those before, but everybody just You do not have to be a rocket scientist to realise represented their department's interest,' he says. that a car maker able to make 2.4m vehicles a year in The new teams are different. Japan, but producing fewer than 1.3m, is running its The CFTs were a device that Mr Ghosn first used in plants at a disastrously low level. To reach 75% America to bring about the merger of Michelin and utilisation, at which point most car firms break even, another tyre company, Uniroyal Goodrich. He also capacity needs to shrink by at least 30%. Under installed them in Renault four years ago. He is Mr Ghosn's plan, Nissan's domestic capacity is to hooked on the cross-functional approach, for several reasons. It works in a crisis, he says, because peoplecan understand the need for rapid action. It makes aims to produce savings of about $1 billion. Mr Ghosn people act outside their specific areas. 'In most hopes to cut costs at Nissan's British plant, already companies people make a specific contribution to Europe's most efficient, by 30%, but thinks more pain the company in their function,' he says. 'But it is not is inevitable. expressed in terms of profit, only in terms of performing their function better.' Instead Mr Ghosn, who meets all the teams monthly, gets them to focus Questions on profit creation, which he reckons lies in the Assume: interstices of different company functions. 'Profit is the most global aspect of a business, and it is cross- a. The second phase of the Ghosn plan does not functional.' come into effect until after the year 2000. The first product of the teams helped to form the b. The target operating profit for 2000 is 100 billion basis of the Nissan revival plan unveiled last October. yen. In the land of lifetime employment (at least for many C. Nissan earns 70 per cent of its revenues from workers in big companies), Mr Ghosn shocked Japan vehicle sales and that other operations break even by announcing the closure of five factories and will do the same in 2000. employing over 16,000 people in Japan alone, d. Average prices of vehicles sold are kept at the cutting capacity by 30% to bring it more into line same level as 1999. with sales and boosting utilisation rates to around e. Taxes are not included in the figures given. the 80% rate. Already machinery is being moved out of the doomed plants into those that will survive, and some 1 Calculate the average price of vehicles sold. workers have been transferred. Strong demand in the 2 Calculate average variable costs for 1999 and the American market (and to a lesser extent in Europe) target for 2000. means that production is actually running about 10% 3 Calculate the size of the overall Japanese vehicle higher than last year, so extra labour is needed in market in 1999. some other Japanese factories. Mr Ghosn hopes to 4 If Nissan can reduce its variable costs in vehicle avoid actually sacking workers, which is expensive in production by 5 per cent in 2000 compared with its Japan. The second phase of his plan - to rationalise target, estimate the effect on profit and return on the Nissan and Renault distribution and dealer sales. networks in Europe - has just been announced, and Explain any assumptions in the above analysis