Hello,

Please help with this case study in its entirety. Including the full MRP plan

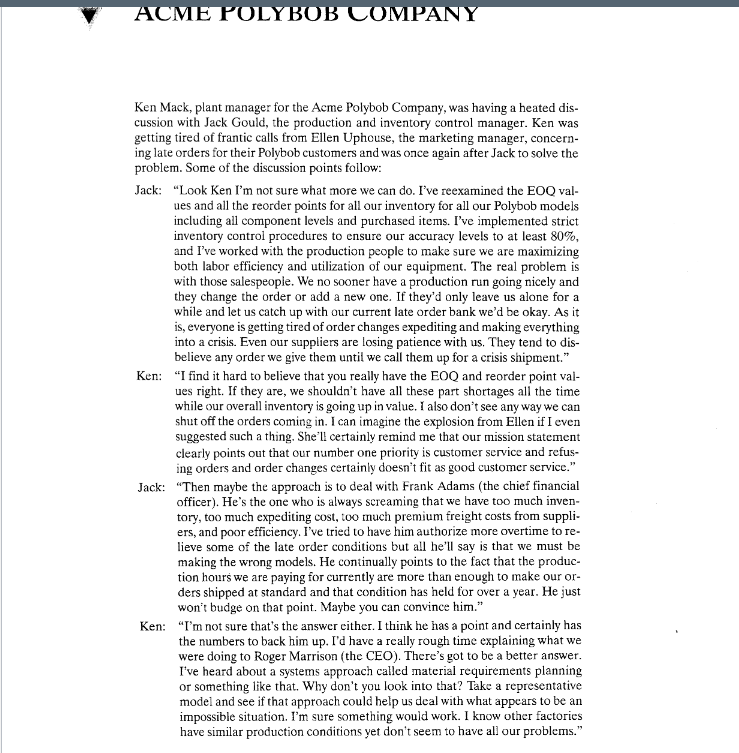

Ken Mach. plant manager for the Acme Polybob Company, was having a heated dis- cussion with Jack Gould, the production and inventory control manager. Ken was getting tired of frantic calls from Ellen Uphouse, the marketing manager, concerna ing late orders fortheirPolyboh customers andwas once again afteriack to solve the problem. Some of the discussion points follow: Jack: \"Look Ken I'm not sure what more we can do. I've reexamined the E00 val- ues and all the reorder points for all our inventory for all our Polyhob models including all component levels and purchased items. I've implemented strict inventory control procedures to ensure our aocmacy levels to at least 3.0%, and I've worked with the production people to make sure we are maximizing both labor efciency and utilization of our equipment. The real problem is with those salespeople. We no sooner have a production run going nicely and they change the order or add a new one. If they'd only leave us alone for a while and let us catch up with our etu-rent late order bank we'd be okay. As it is, everyoue is getting tired of order changes expeditingand making everything into a crisis. Even our suppliers are losing patience with us. They tend to dis belieye any order we give them until we call them up for a crisis shipment.\" Ken: \"I find it hard to believe that you really have the E00 and reorder point val ues right. If they are, we shrmldn't have all these part shortages all the time while :nlrrnrerall inventory isgoing up in value, I nlsodon't see anyway we can shut offdie orders coming in. I can imagine the explosion from Ellen ii I even suggested such a thing. She'll oertainly remind me that our mission statement clearly points out that our numher one priority is customer service and refus- ing orders and order changes certainly doesnit fit as good customer service." Jack: \"Then maybe the approach is to deal with Frank Adams {die chief nancial officer). He's the one who is always screaming thatwe have too much inven- tory, too much expediting oost. too much premium freight costs from suppli- ers, and poorefeiency. I've tried to have him authorize more overtime to re- Iierre some of the late order conditions but all he'll say is that we must be making the an-ong models. He continually points to the fact that the produc- tion hours we are paying for currently are more than enough to malt-e our or- der: shipped at standard and that condition has held for over a year. He just won't budge on that point. Maybe you can connes him.\" Ken: \"I'm not sure that's the answer either. I think he has a point and certainly has the numbers so back him up. I'd have a really rough time estplainingwhar we were doing to Roger Harrison (the CEO}. There's got to be a better answer. I've heard about a systems approach called material requirements planning or something like that Why don't you look into that? Take a representative model and see if that approach could help us deal with what appears to be an impossible situation. For sure something. would work. I know other factories have similar production conditions yet don't seem to have all our problems." \f